Unparalleled BOM Management

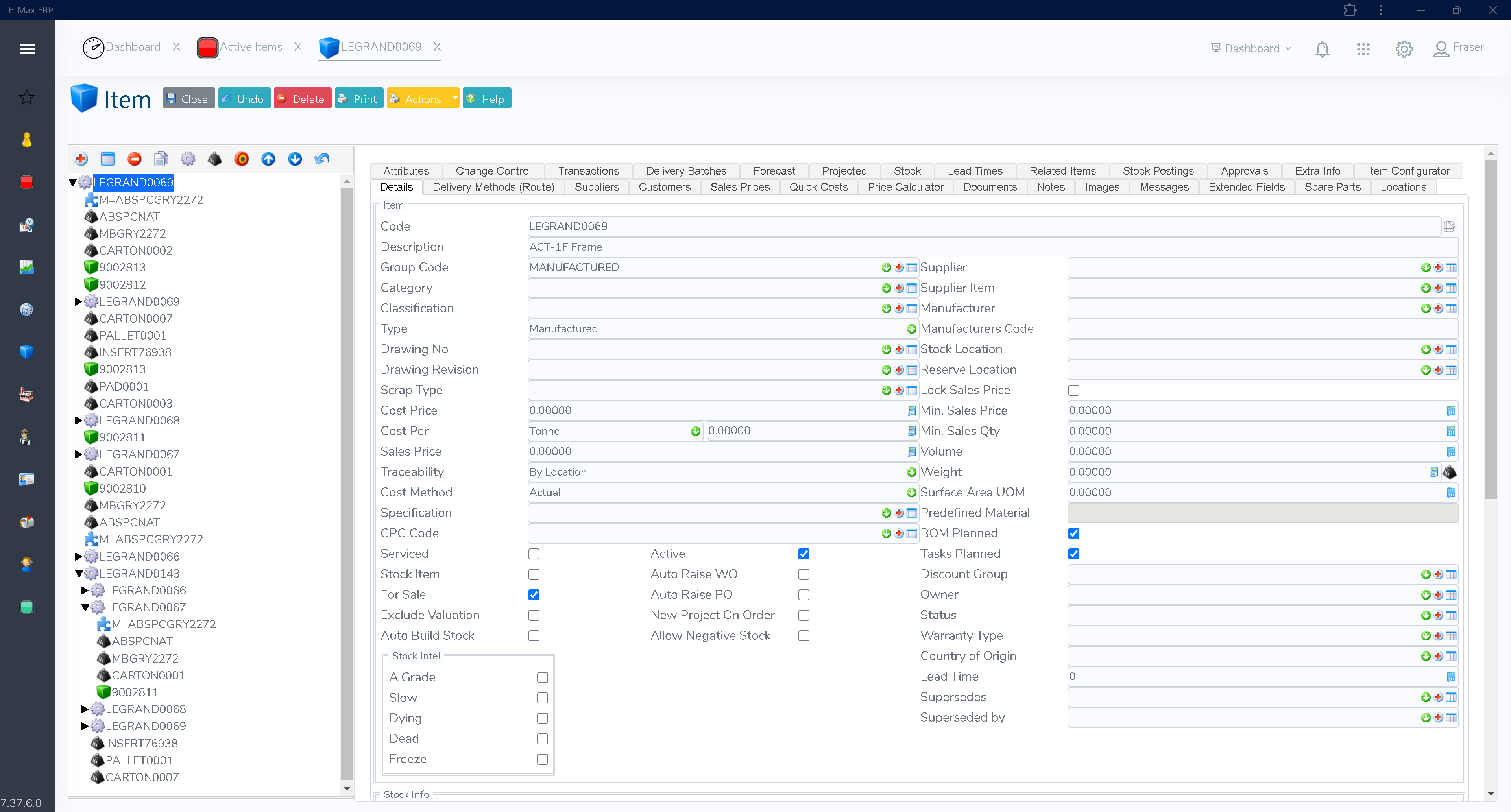

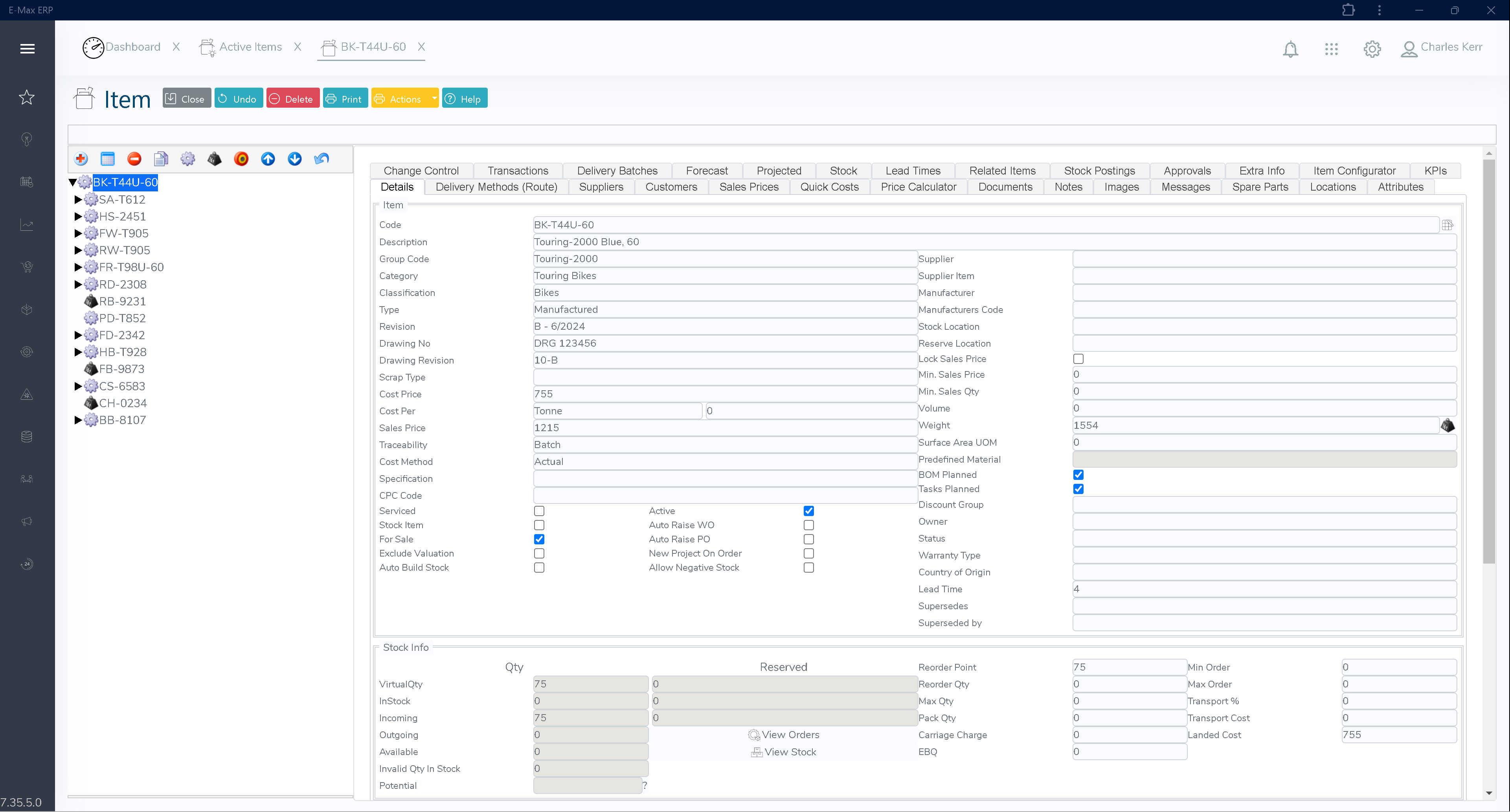

Make managing large BOMs much easier. E-Max ERP is designed to capture and manage large volumes of data, effectively handling even the most complex multi-level BOM. Whether it’s specifying which supplier or manufacturer (and permitted alternatives to each) can be used in that BOM or structuring multiple sub-assemblies for easier management of staged production, E-Max will streamline and speed up your BOM management process for even the most complex manufactured electronic products.Import Multiple File & BOM Formats

Using alternative software solutions to design products? Data from these can be quickly and smoothly imported directly into E-Max ERP, saving time and reducing the risk of manual errors. Existing BOMs can be copied and edited for new or updated products.Item Revisions and Version Control

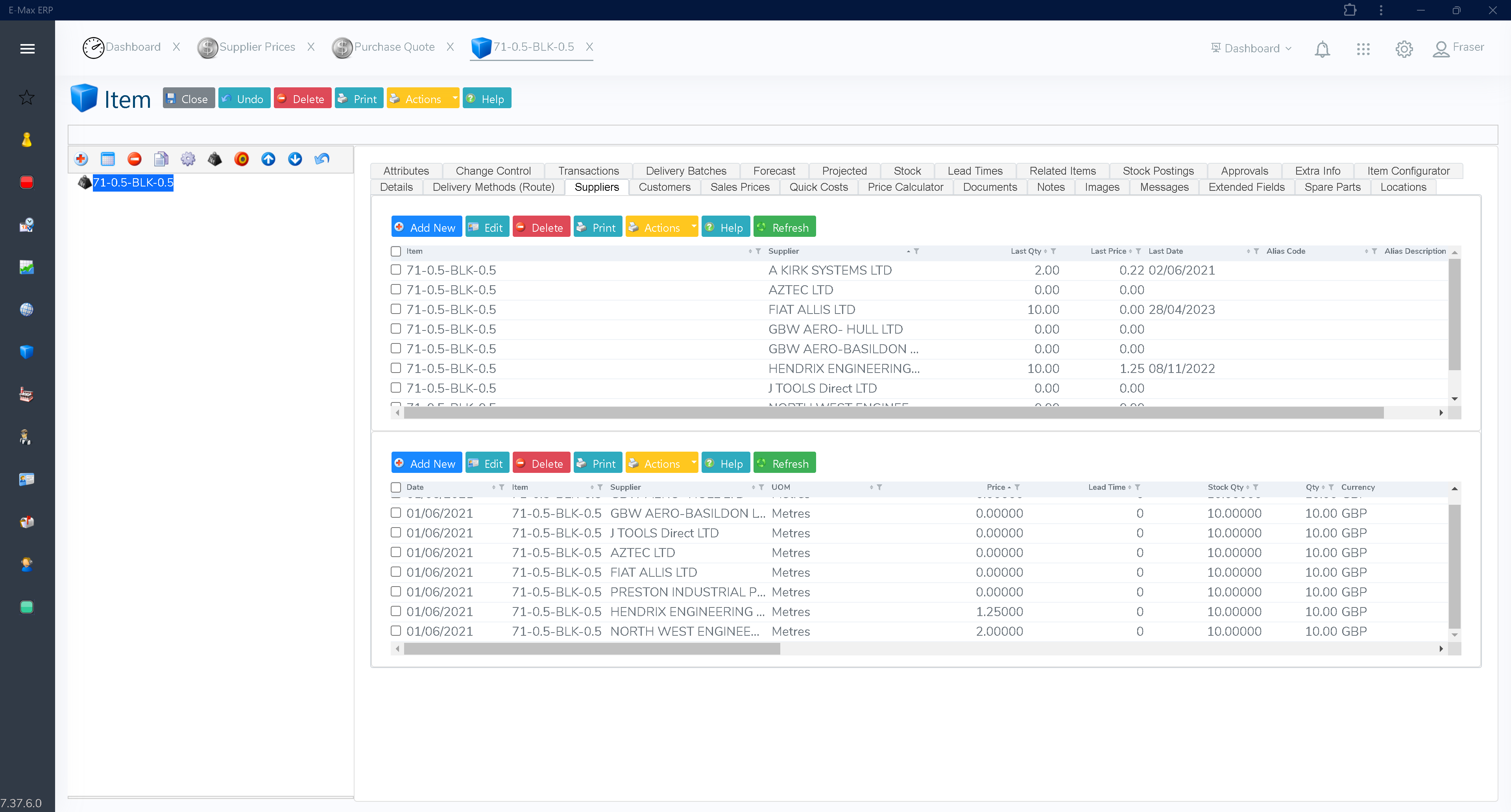

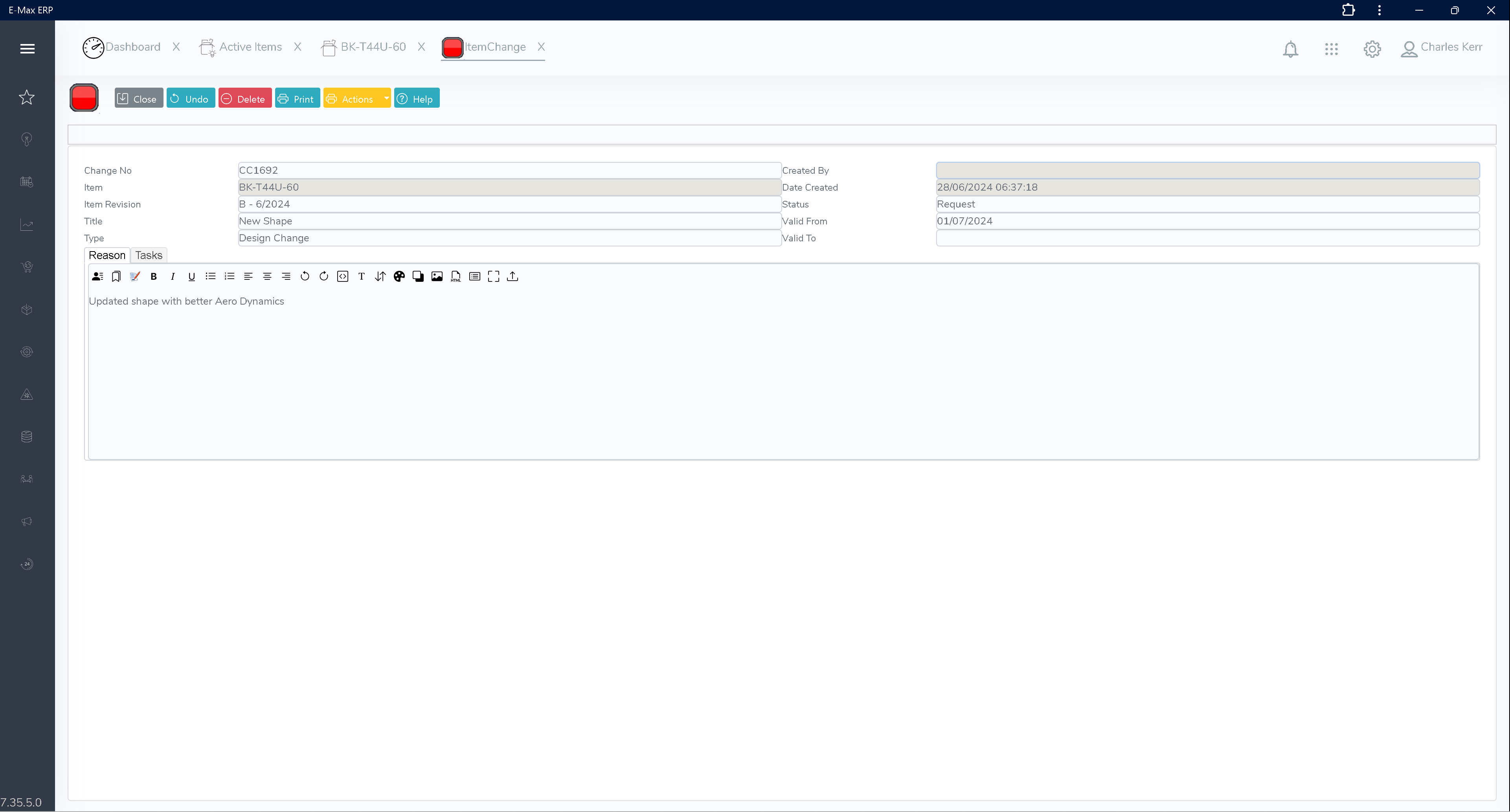

Achieve clear visibility and control of each different version of a BOM or route. Manage product updates, design modifications or improvements, and track all revisions with E-Max’s product lifecycle management.Apply Multiple Part Numbers

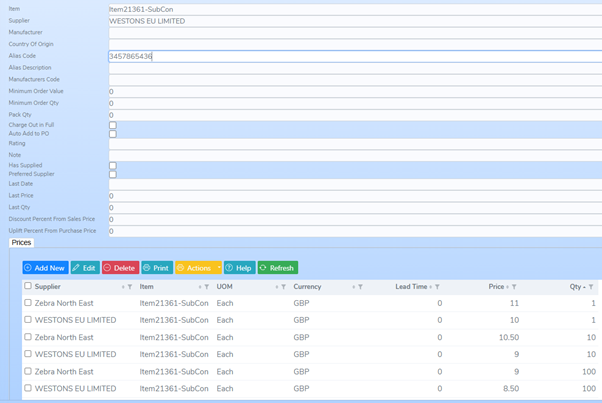

Each part can be allocated unlimited alias codes per supplier and per customer.Comprehensive Supplier Management

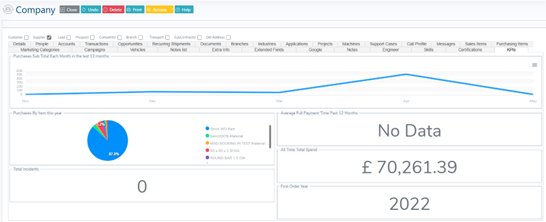

E-Max ERP keeps your supply chain moving smoothly by allowing you to effectively manage your supplier relationships. Set supplier ratings, approval status and credit limits and easily identify reliable and efficient suppliers. View the full history of transactions with each supplier.Manage Supplier Prices

Automatically apply supplier pricelists, including quantity break prices and lead times, and make the most effective, informed purchasing decisions. Pricelists are updated automatically as responses to RFQs are received or can be updated in bulk when new pricelists are received.Full Traceability

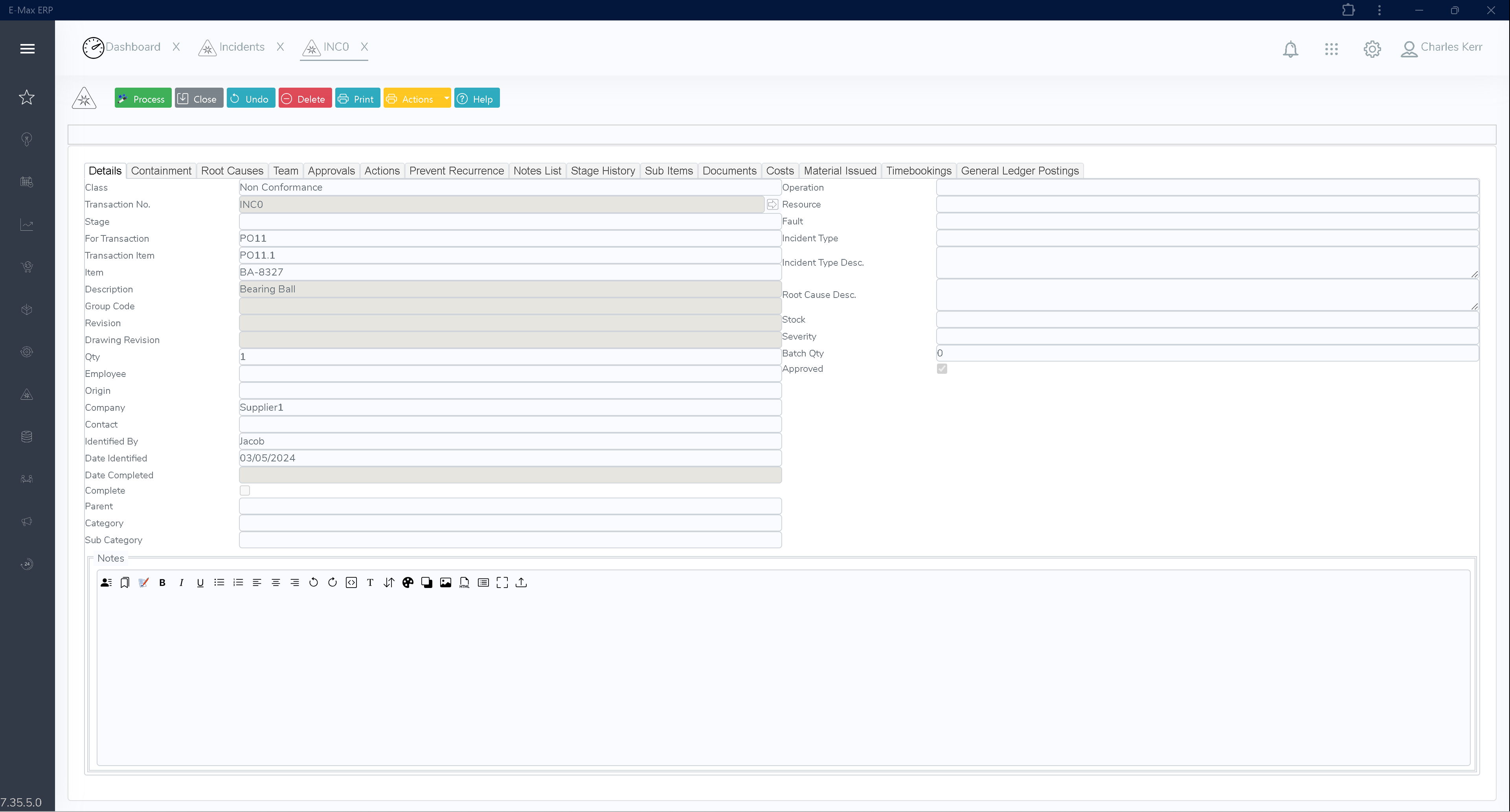

Easily track and manage raw materials, components, and finished products from supplier, through the production process, and onto the end customer. E-Max ERP’s traceability functionality automatically records and archives all data, including materials in and finished items, producing appropriate documentation, such as certificates of conformance, non-conformance or incident reports, and test certificates. Track by batch, serial or lot numbers, or by date, including First In First Out (FIFO), Last In First Out (LIFO), and Use By.Optimal Production Planning

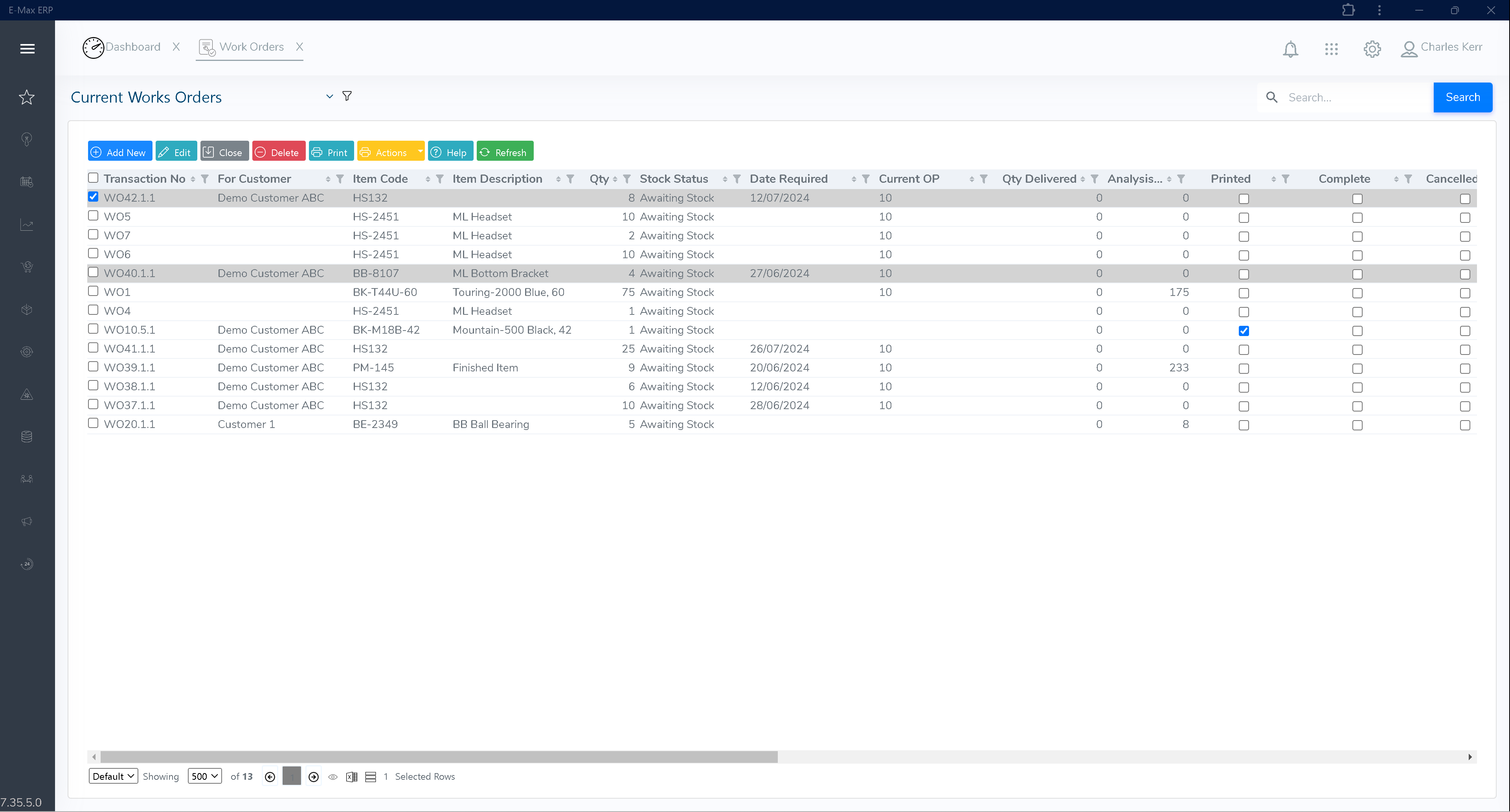

Take your MRP to the next level with E-Max ERP as you plan, monitor and organise your resources to meet customer deadlines. E-Max ERP allows you to schedule activities, taking into account availability of labour, including specific skill levels, machinery, tools, and workstations to create optimal production plans. In addition to daily, weekly, and monthly planning, our MRP functionality can be used for long term planning and forecasting.Item Variants

With E-Max ERP you can store multiple manufacturing versions and routes for an item. Ideal for companies that offer customisable or configurable products to meet diverse customer needs. E-Max also offers ECN and change control options.Kitting

Streamline your picking and packing process further by creating kits. Use E-Max’s BOM to specify components and quantities and store them in easily accessible locations under a separate SKU or item number.Used and Trusted by Electronics Manufacturers

View Key Analytics and Reporting for Electronics Manufacturing

See the KPIs that matter to you on E-Max's customisable dashboards. Track work orders, stock levels, quality, production targets, waste and costs and understand exactly how your electronics manufacturing business is performing.Comprehensive CRM

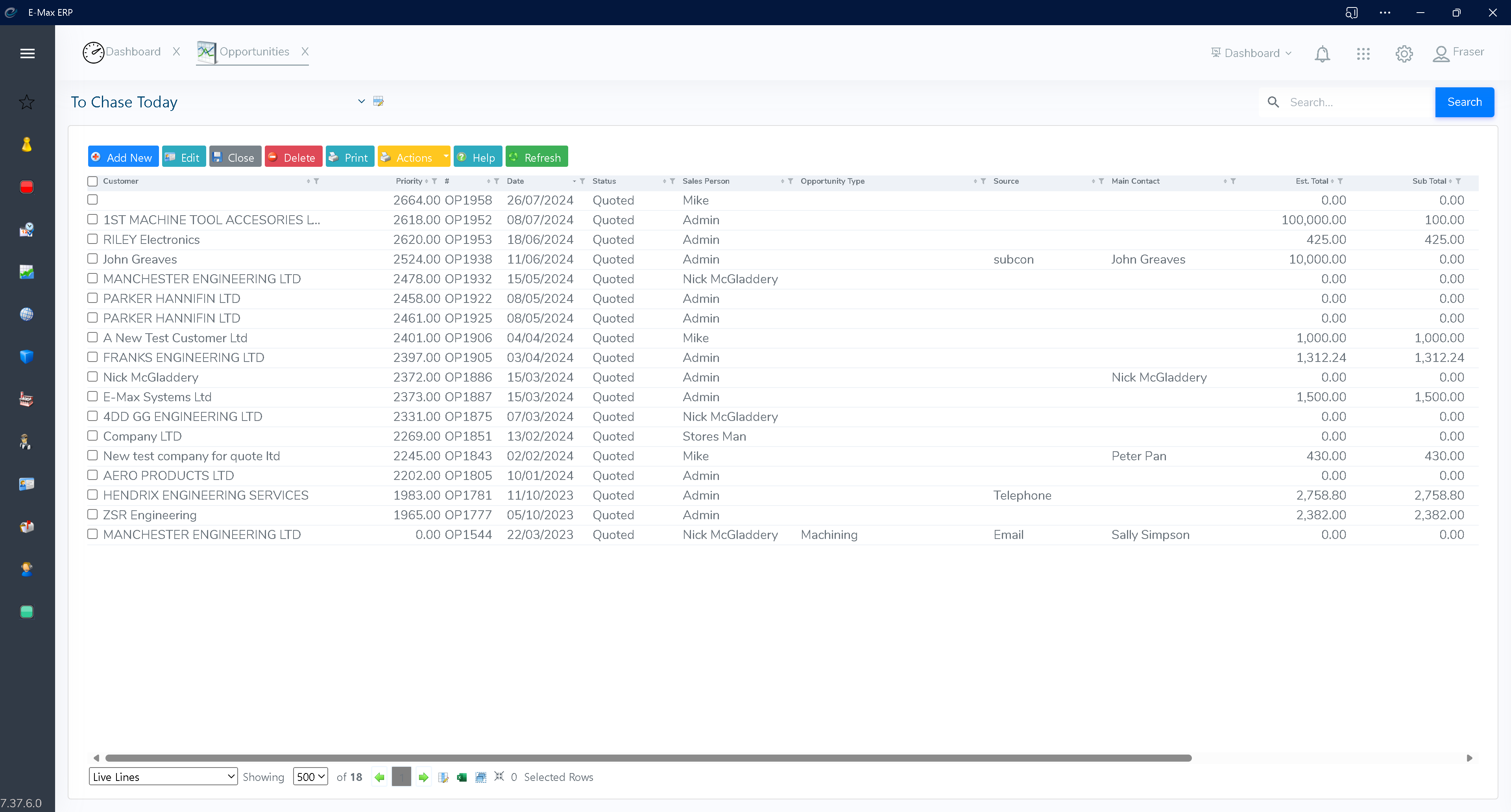

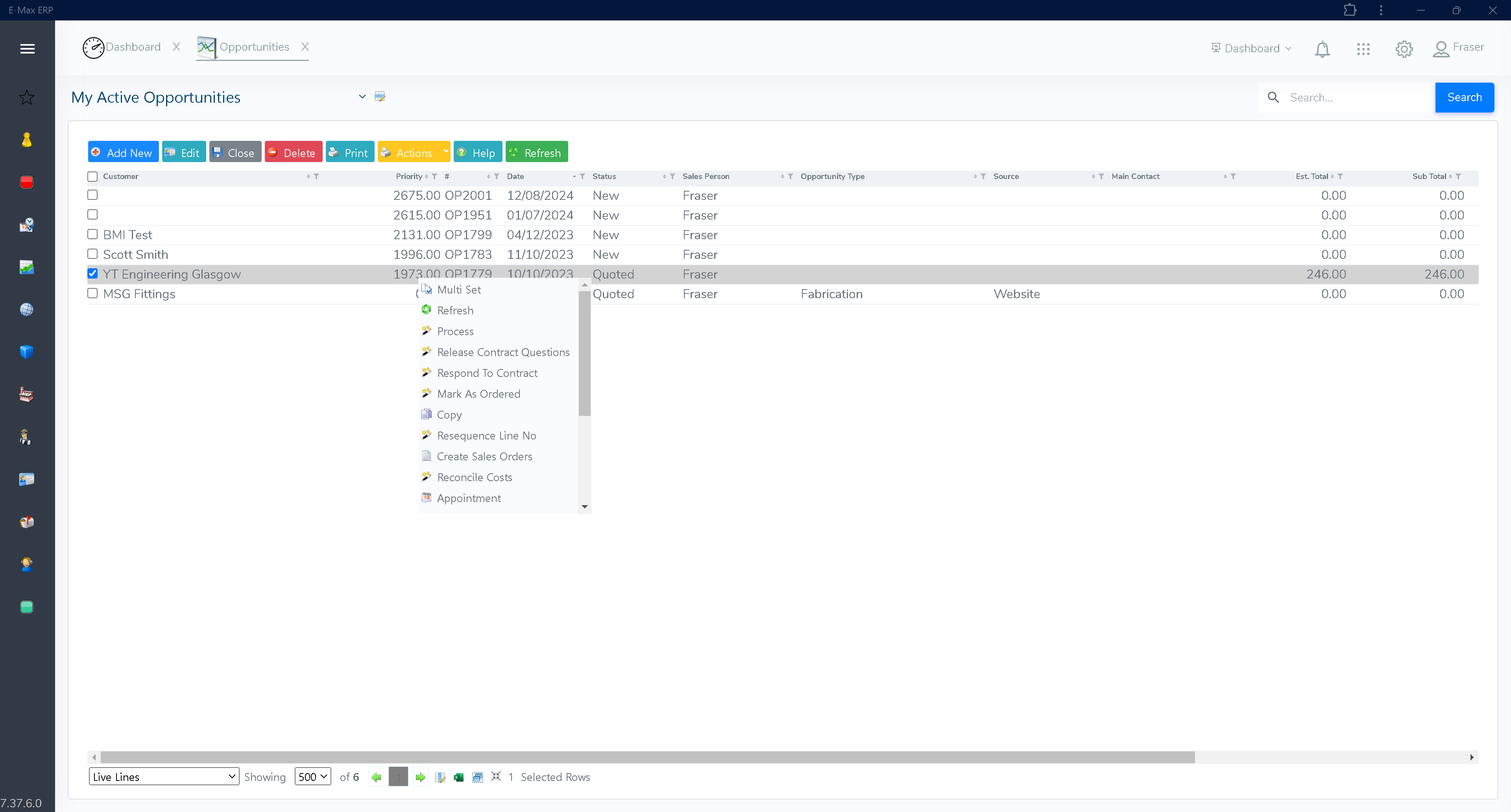

Our CRM module enables you to efficiently manage your leads, track opportunities, and convert these into sales. Generate quick quotes and leverage the data in E-Max to provide fast, accurate and efficient responses to RFQs and manage existing customer relationships.Workflow Automation

Instantly convert sales quotes to orders, raise purchase orders from works orders and create production schedules. By integrating sales, purchasing, inventory and production, jobs flow seamlessly through the system without any duplication or manual error.Document Management

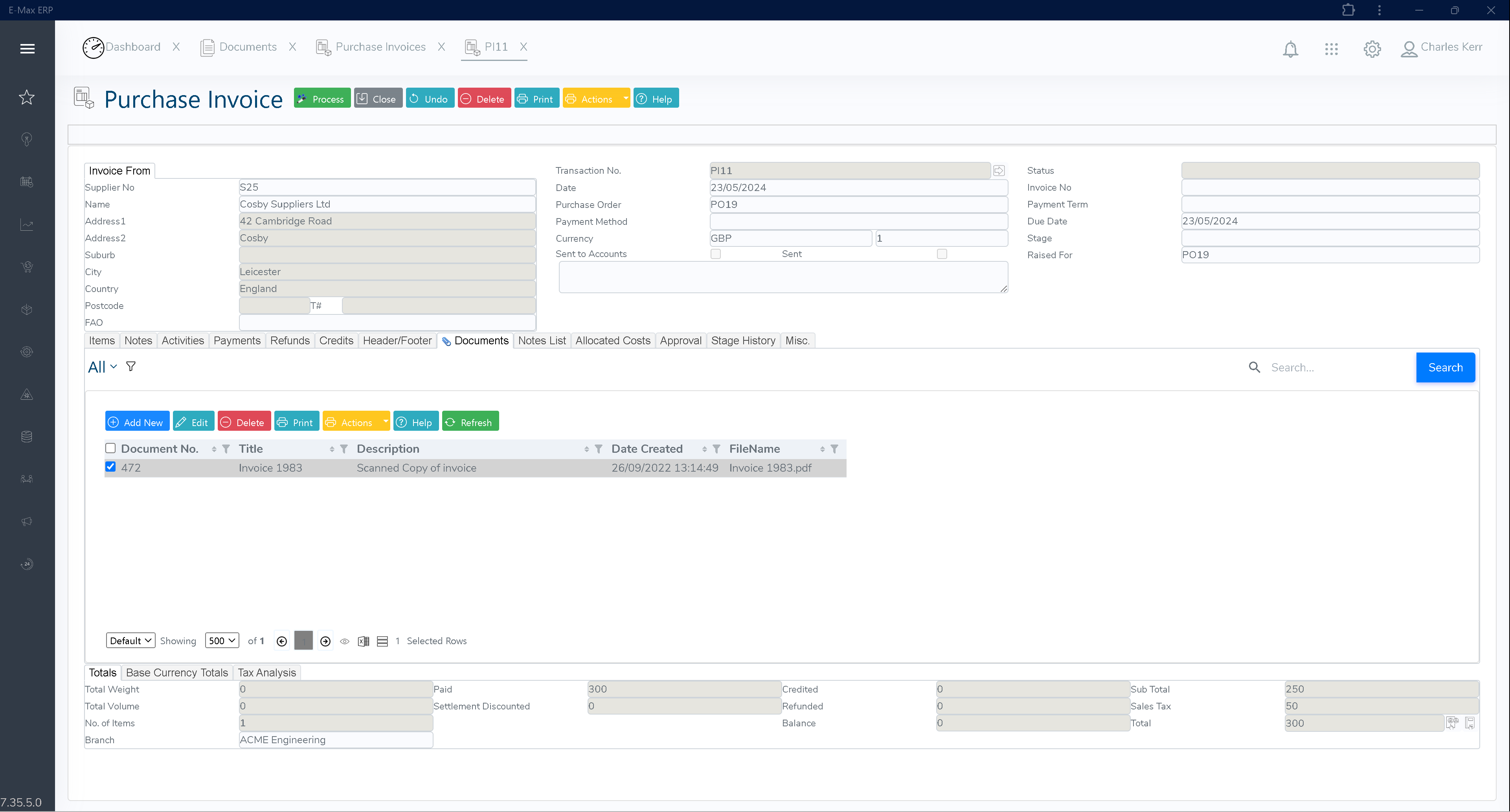

Use the flexibility of E-Max ERP to link any type of document against any transactions in E-Max, including sales orders, works orders, invoices, expenses, etc. Link critical documents like drawings, test results, procedures, images, instructions, and even chemical analysis to any job or operation and access every related document easily and quickly from anywhere within E-Max.Effective Stock Management

Track your inventory in real-time, send automated alerts when stock levels fall below a certain threshold, and use barcodes to quickly and accurately identify, locate and update your inventory levels. E-Max ERP enables you to fulfil all your stock requirements, reduces excess inventory held, and improves your overall inventory accuracy.Integrated Quality System

E-Max ERP includes a robust quality system designed to monitor, control and improve the quality of production. Record non-conformances, identify root causes and make improvements. Find out more: link to actual quality page.Stay Compliant and Manage Accreditations

E-Max ERP makes it easy to create and follow processes to ensure your team is compliant with current regulations, including RoHS and CoSHH. E-Max ERP can also be used to achieve and retain industry accreditations such as ISO 9001 and offers a full audit trail to demonstrate compliance with the required standards. The system will also generate reports and documentation required for regulatory purposes.Shopfloor Management

Schedule and monitor your production activities on the shop floor. E-Max ERP tracks the progress of work orders, manages work-in-progress, and ensures that production processes are performed efficiently.E-Max ERP Software

offers all of this and more:

.png)

.png)

.png)

.png)

.png)

.png)

.png)