Bill of Materials (BOM)

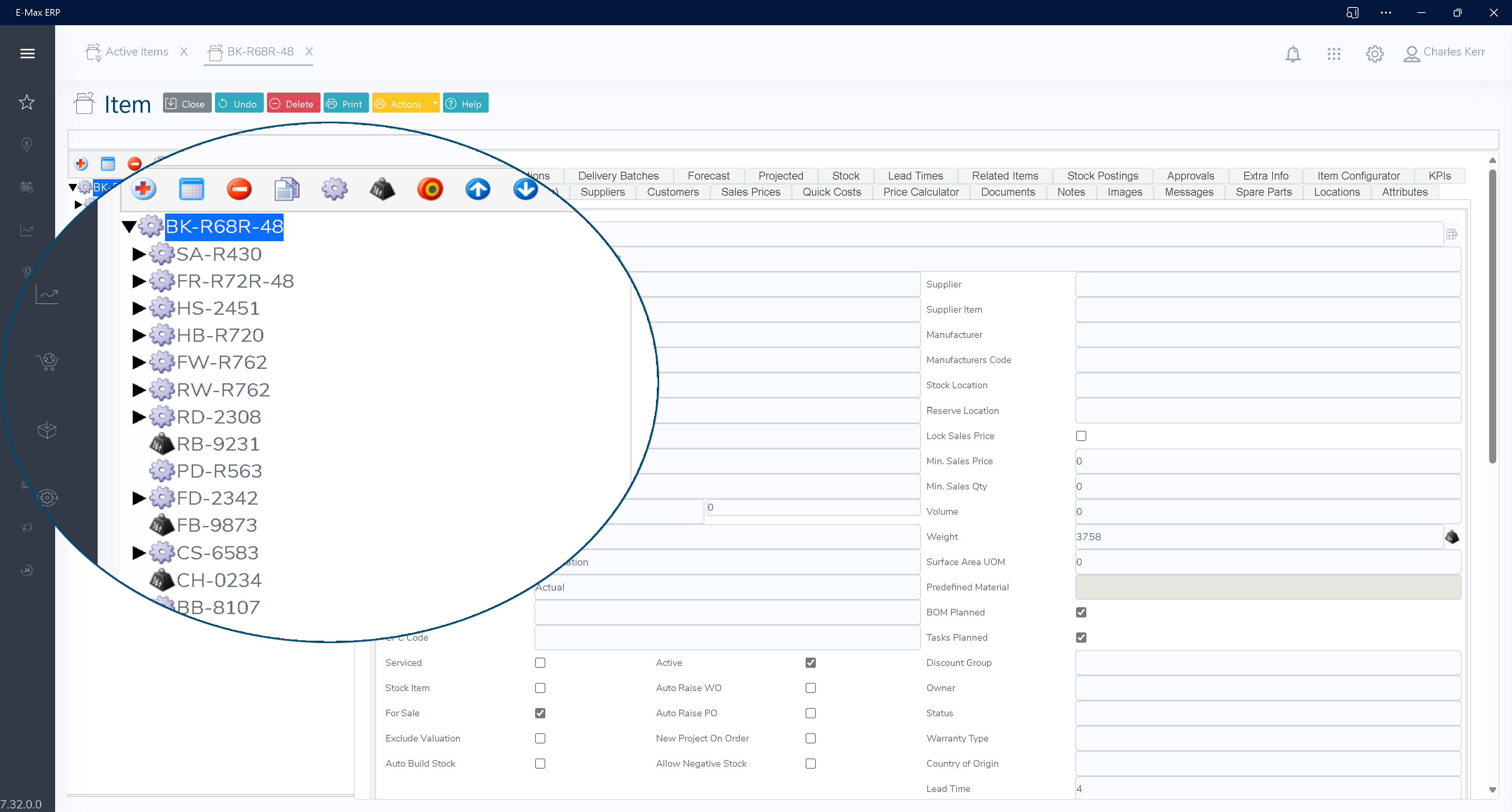

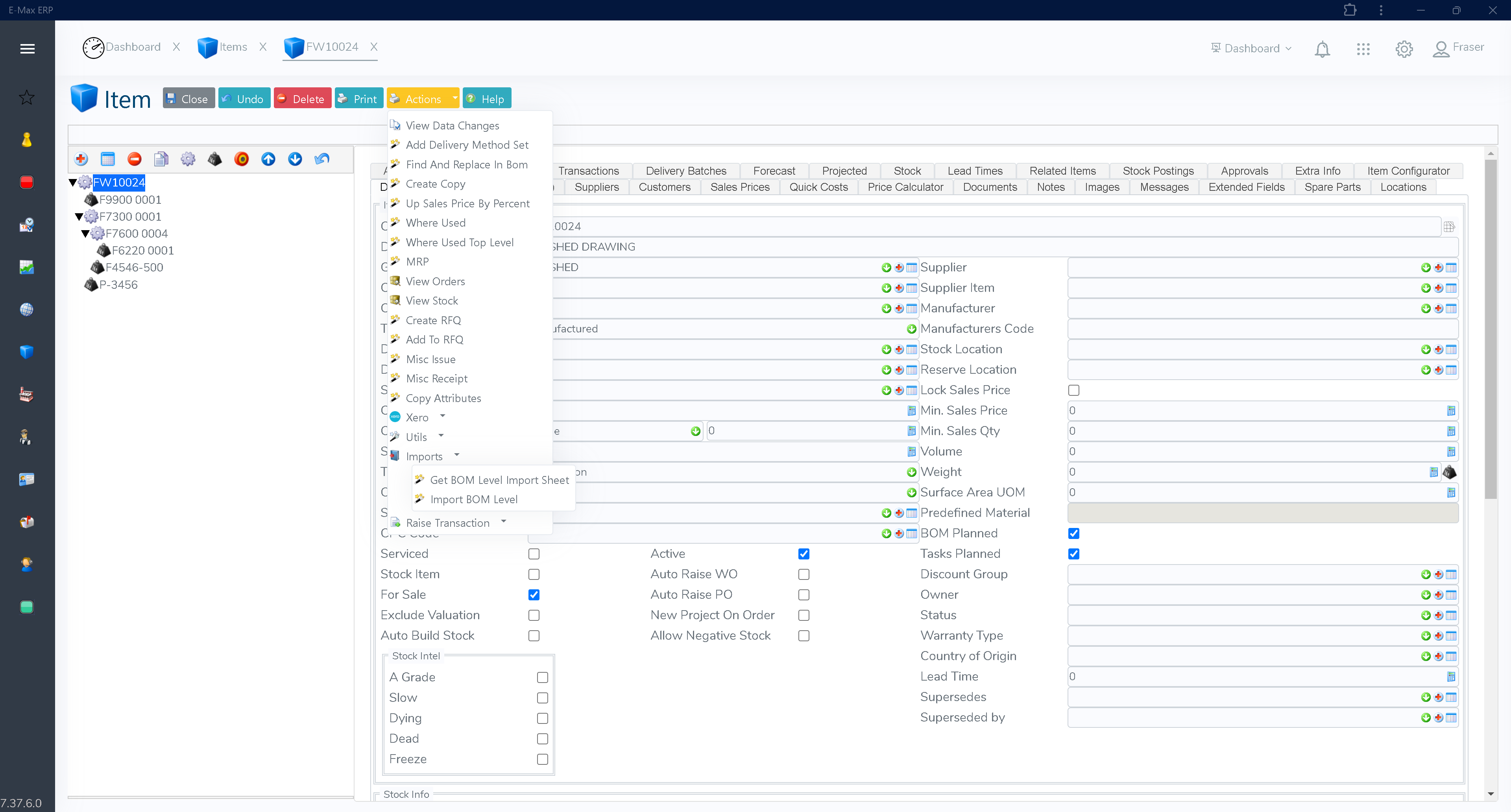

E-Max’s bill of materials allows you to accurately define all the components, materials, parts, subassemblies and quantities required to manufacture a finished product. Starting with the finished product at the top, its hierarchical structure allows infinite multi-level BOMs of unlimited size. Save time by duplicating existing BOMs, use the tracking history to record revisions (ideal for audit purposes), and import BOMs from other software packages, including Excel and CAD packages. Included in E-Max ERP’s BOM is a standard item configurator.BOM Imports

Avoid manual errors and save time by transferring data to E-Max ERP quickly and conveniently from multiple software packages, including CAD and CSV formats. Data can also be extracted from E-Max and fed into CAD packages.BOM Control

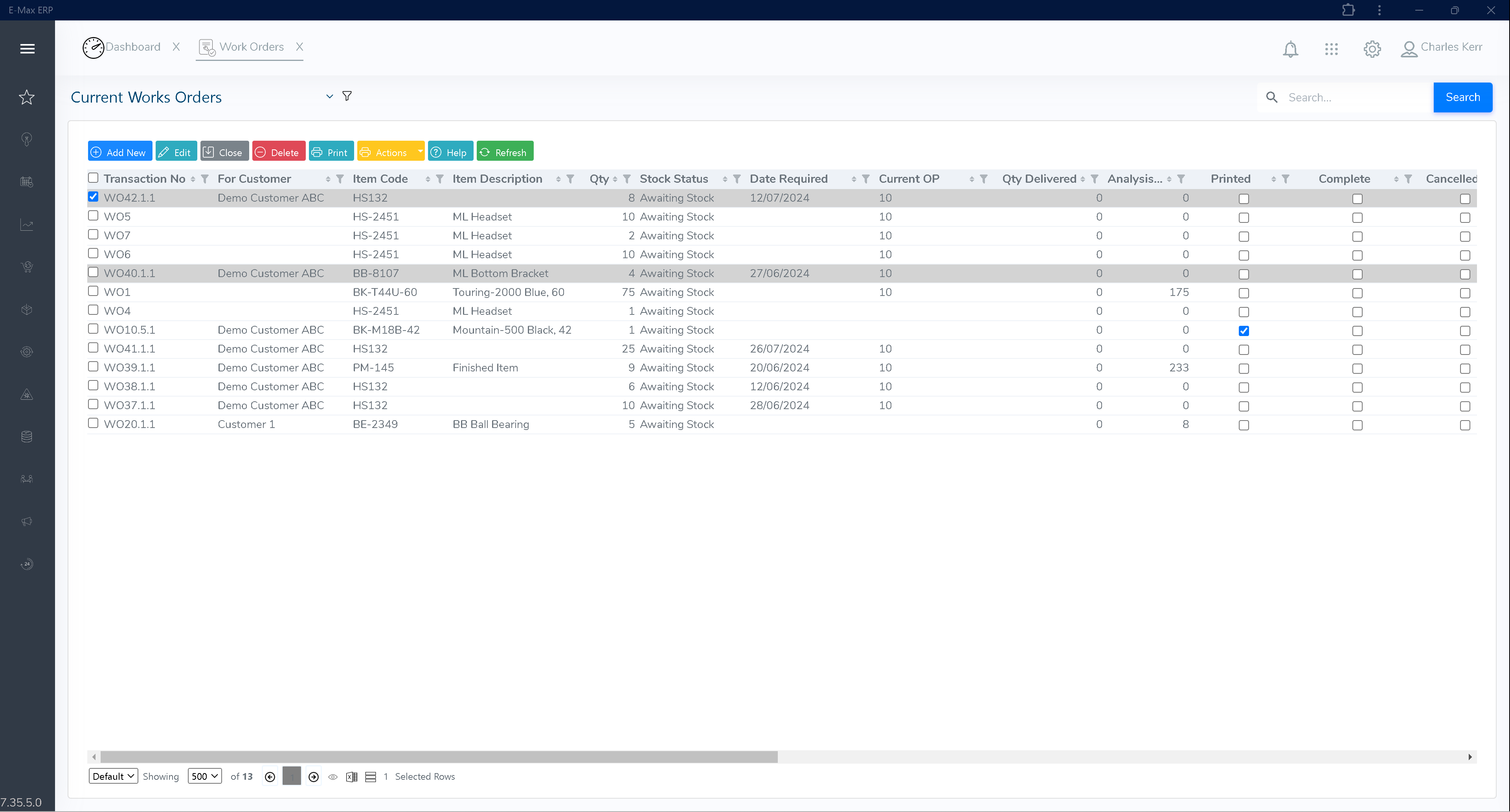

Manage every change or update to your BOM across components, sub-assemblies and materials with E-Max’s BOM control. Once approved, our Version Control records and stores the full history of BOM revisions.Works Order Management

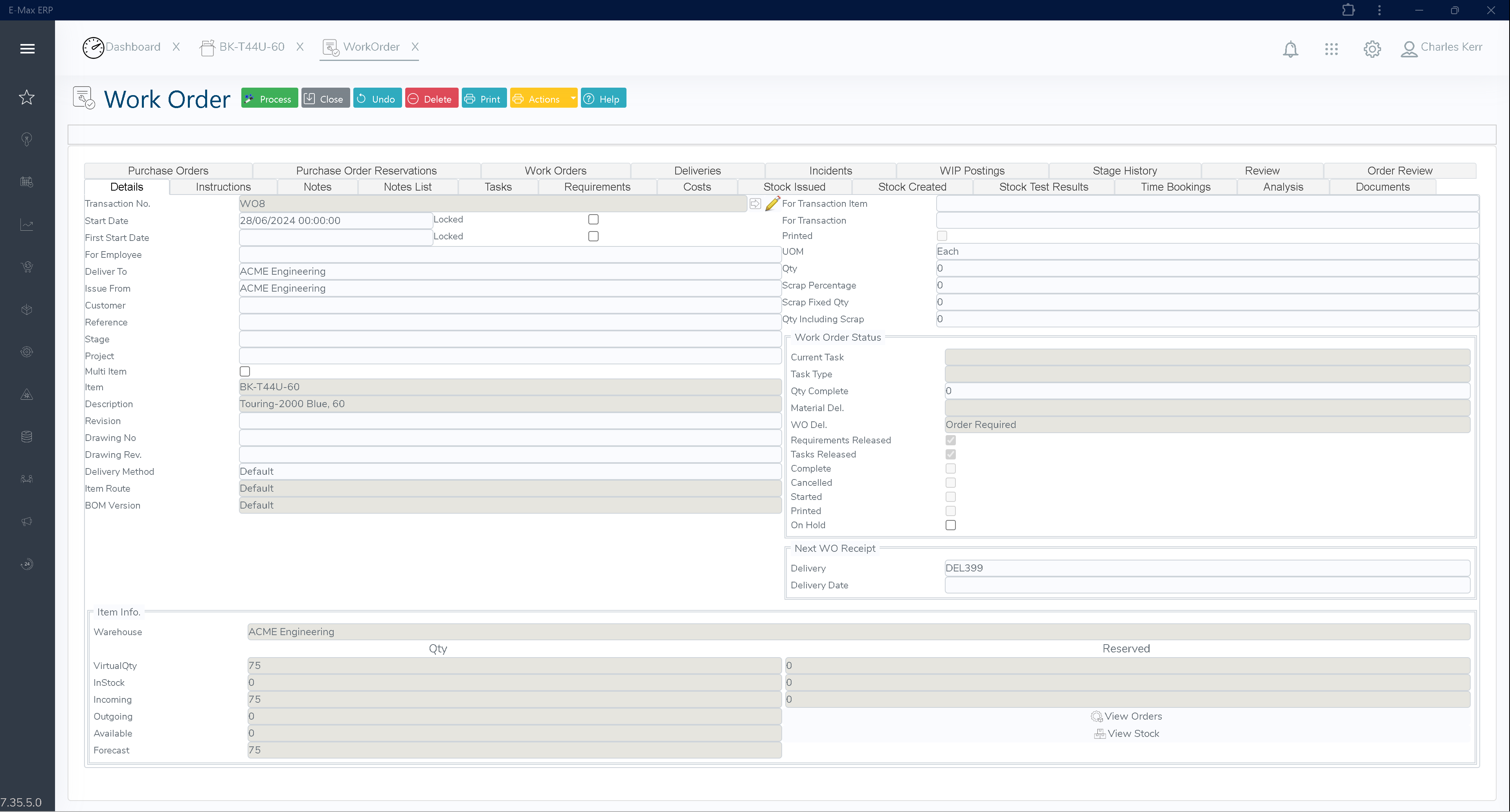

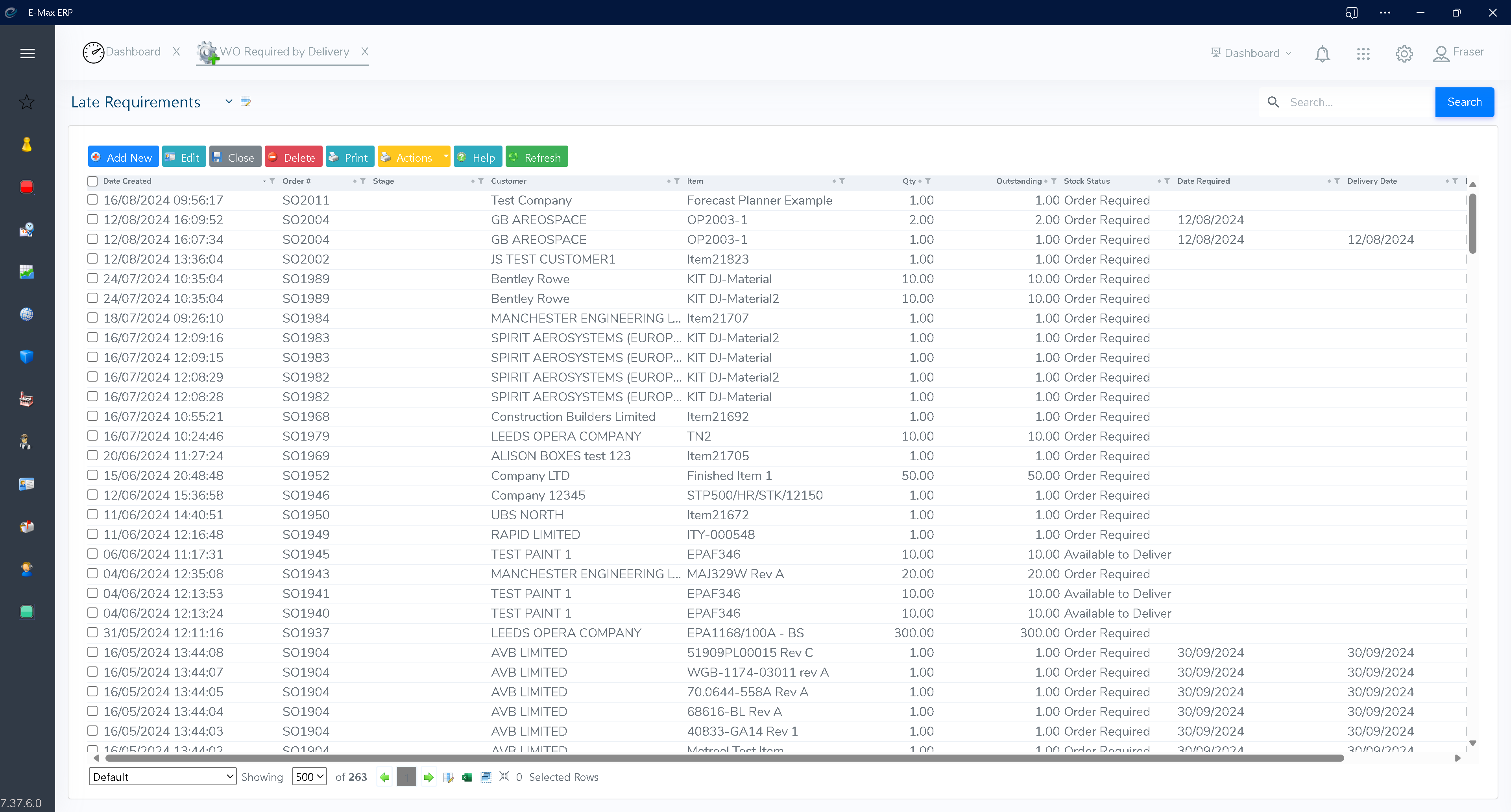

Generate works orders in a single click with E-Max ERP and keep your production moving. Guide your production team, coordinate your resources and ensure every job is manufactured to a quality standard and schedule. E-Max ERP supports multi-item works orders, allowing for nesting and by-products being returned to stock.Used and Trusted by Metal Fabricators

Stock Management

Accurately track inventory levels and ensure you have the necessary materials to complete each job. The most cost-effective materials for each job are easily identified. With E-Max you can also minimise waste by optimising use of raw materials, saving time, material, and cost by using the use the same piece of raw material across different jobs. These split costs can then be allocated to the relevant job. Our Warehouse Management ensures that stock can be easily identified and located.Multiple Unit of Measure (UOM) & Conversions

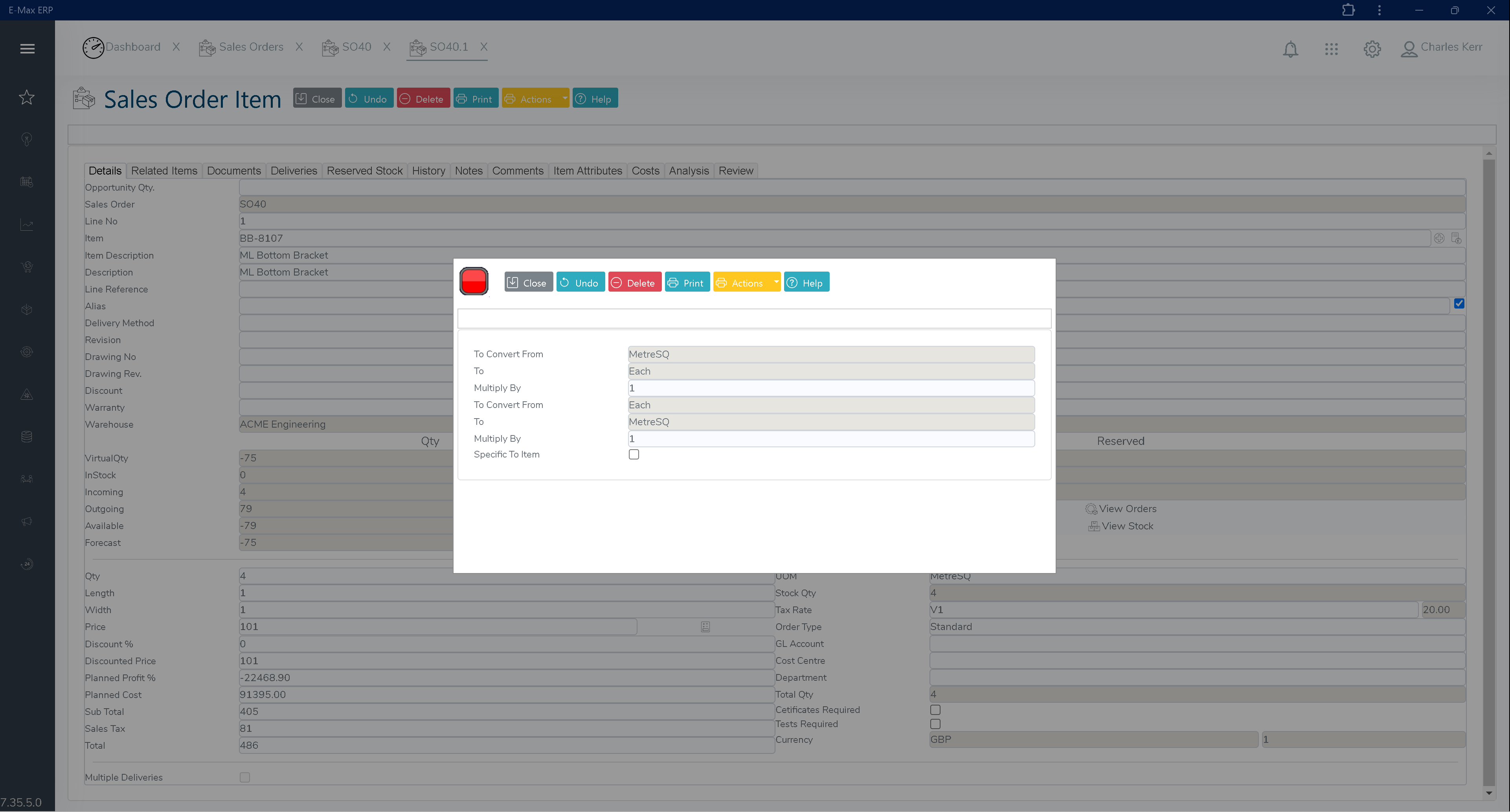

E-Max ERP gives you the ability to measure materials precisely, based on your preferences. Stay in control of various units of measurement for your inventory. Establish conversion ratios directly within the system, ensuring seamless management of sales, purchases, and stock transactions. The system will seamlessly manage all conversions on your behalf.Manage Scrap

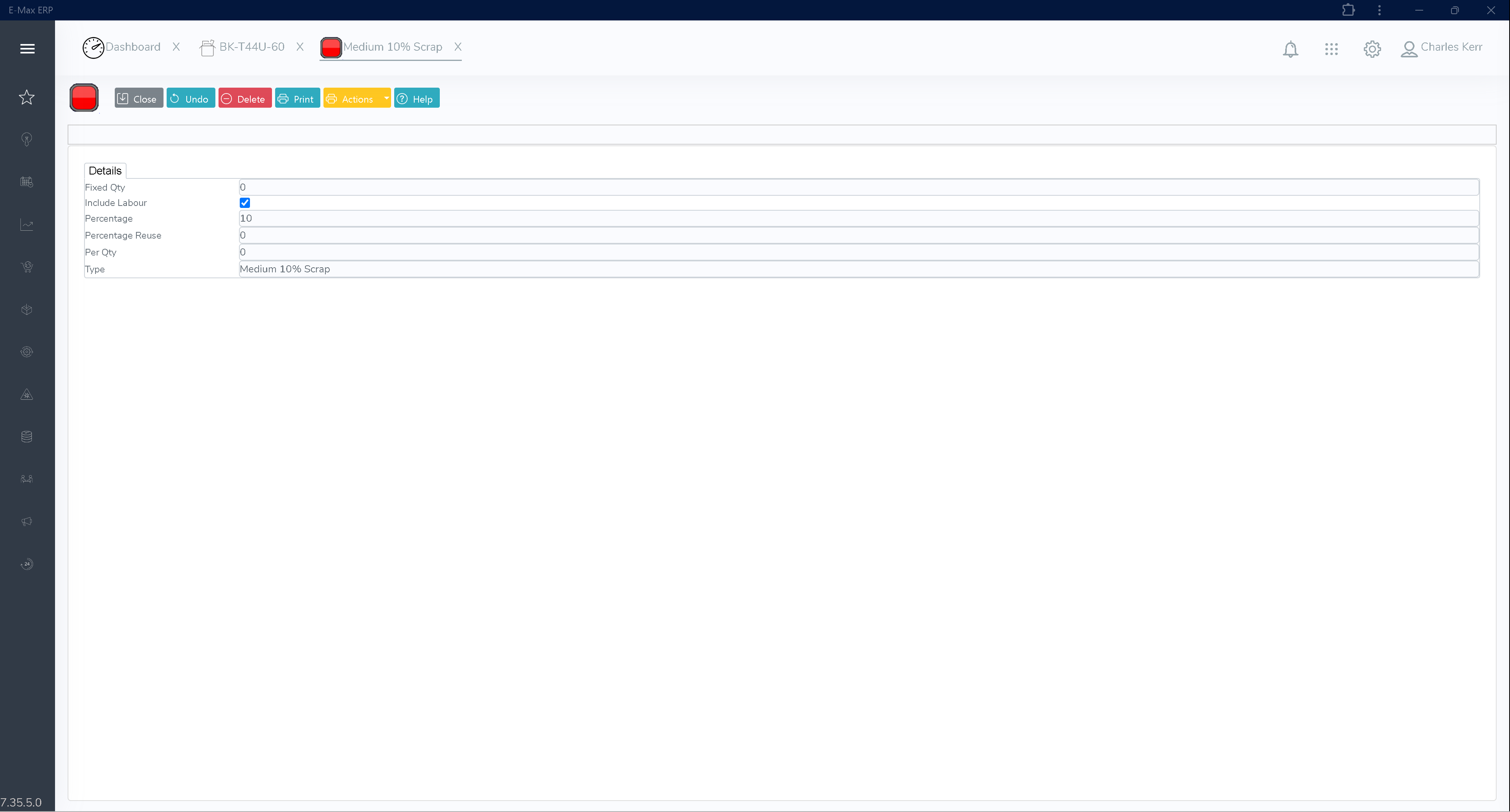

Avoid material shortages and account for all material costs by recording scrap or wastage information. E-Max ERP allows you to apply a fixed quantity and/or percentage to all items, either purchased or manufactured, for accurate materials management. Fixed and percentage scrap is also handled at every level in our BOM.Full Traceability

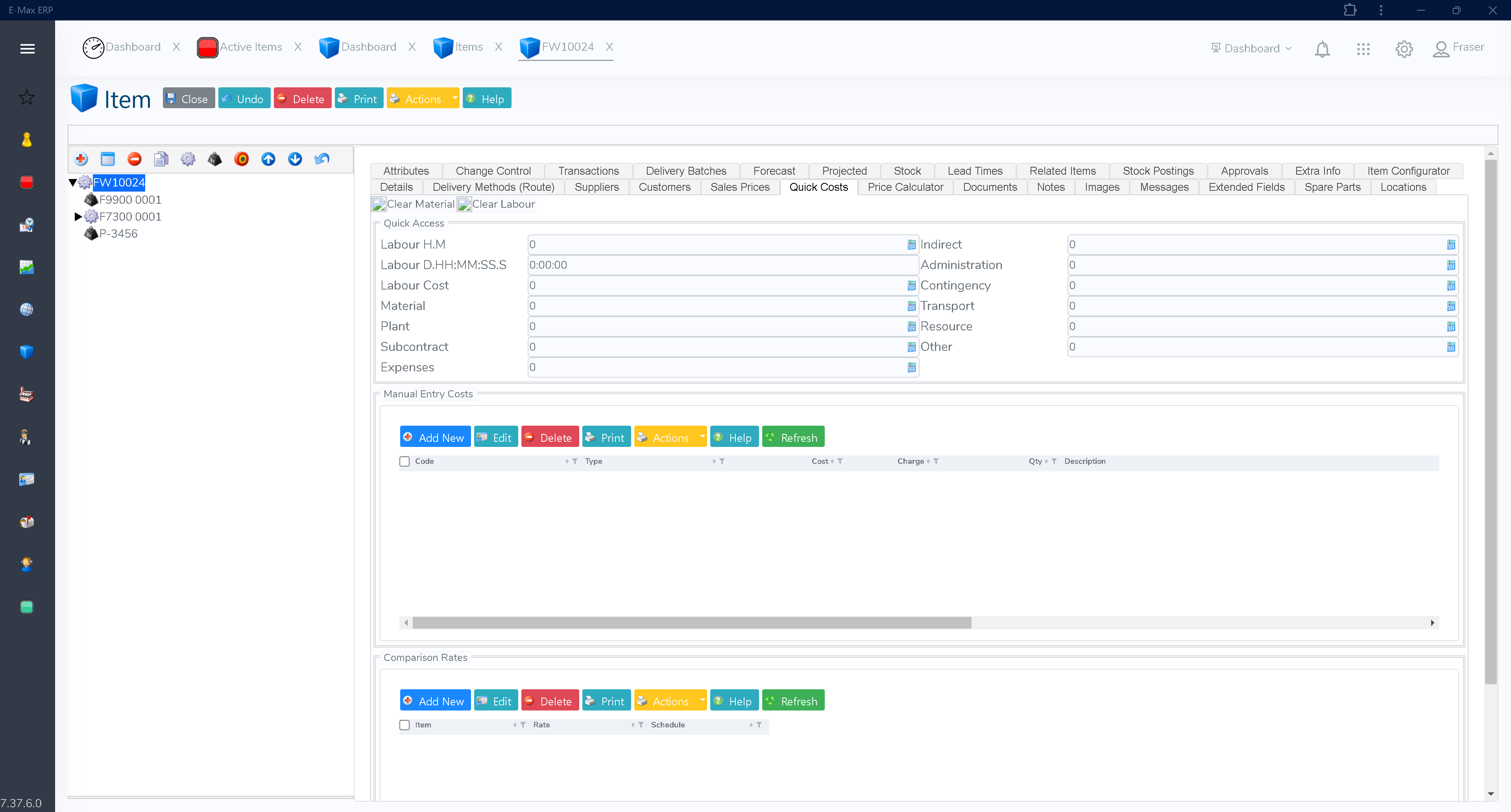

E-Max ERP tracks materials in real time across your operations, not just in the warehouse. Track by batch, serial or lot numbers, or by date, including First In First Out (FIFO), Last In First Out (LIFO), and Use By.Accurately Track Job Costs

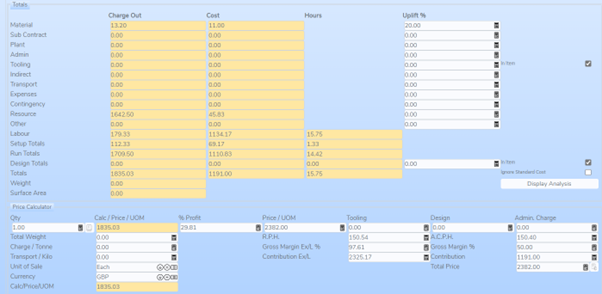

Assign different labour rates to individuals and calculate the time they spent on each job. E-Max ERP also calculates the total weight and cost per tonne of the fabrication.Manage Your Resources Effectively

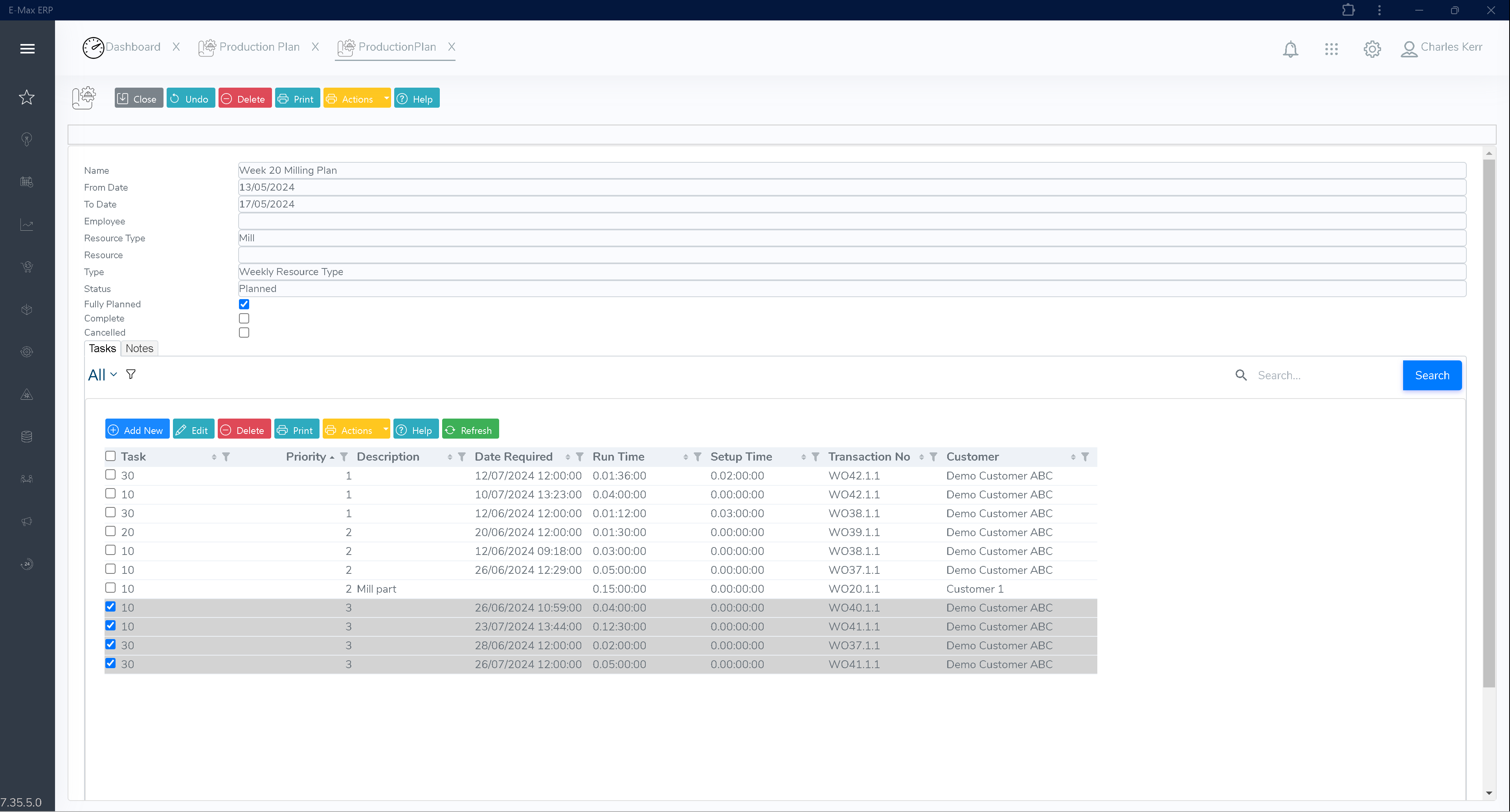

Take your MRP to the next level with E-Max ERP as you plan, monitor and organise your resources to meet customer deadlines. E-Max ERP allows you to schedule activities, taking into account availability of labour, including specific skill levels, machinery, tools, and workstations to create optimal production plans. In addition to daily, weekly, and monthly planning, our MRP functionality can be used for long term planning and forecasting.Key Analytics and Reporting for Metal Fabrication

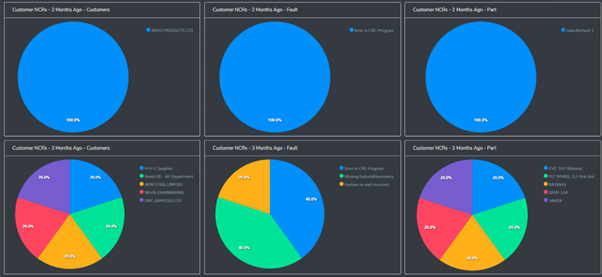

View the KPIs that matter to you on E-Max's customisable dashboards. Track work orders, stock levels, quality, production targets, waste and costs and understand exactly how your metal fabrication business is performing.Revision Control

Manage product updates, design modifications or improvements with E-Max’s Revision control. Once approved, our Version Control records a full history of revisions with every drawing change stored in E-Max's Drawing Register.Improve Supply Chain Management

Get real time insights into your operations and manage the flow of materials through your business. E-Max uses current and historical data to analyse and forecast future demand and calculate stock requirements, source materials and plan production activities and end delivery. Bringing all your data together provides a holistic view and allows leaders to spot opportunities for efficiency improvements.Shopfloor Management

Schedule and monitor your production activities on the shop floor. E-Max ERP tracks the progress of work orders, manages work-in-progress, and ensures that production processes are performed efficiently.Workflow Automation

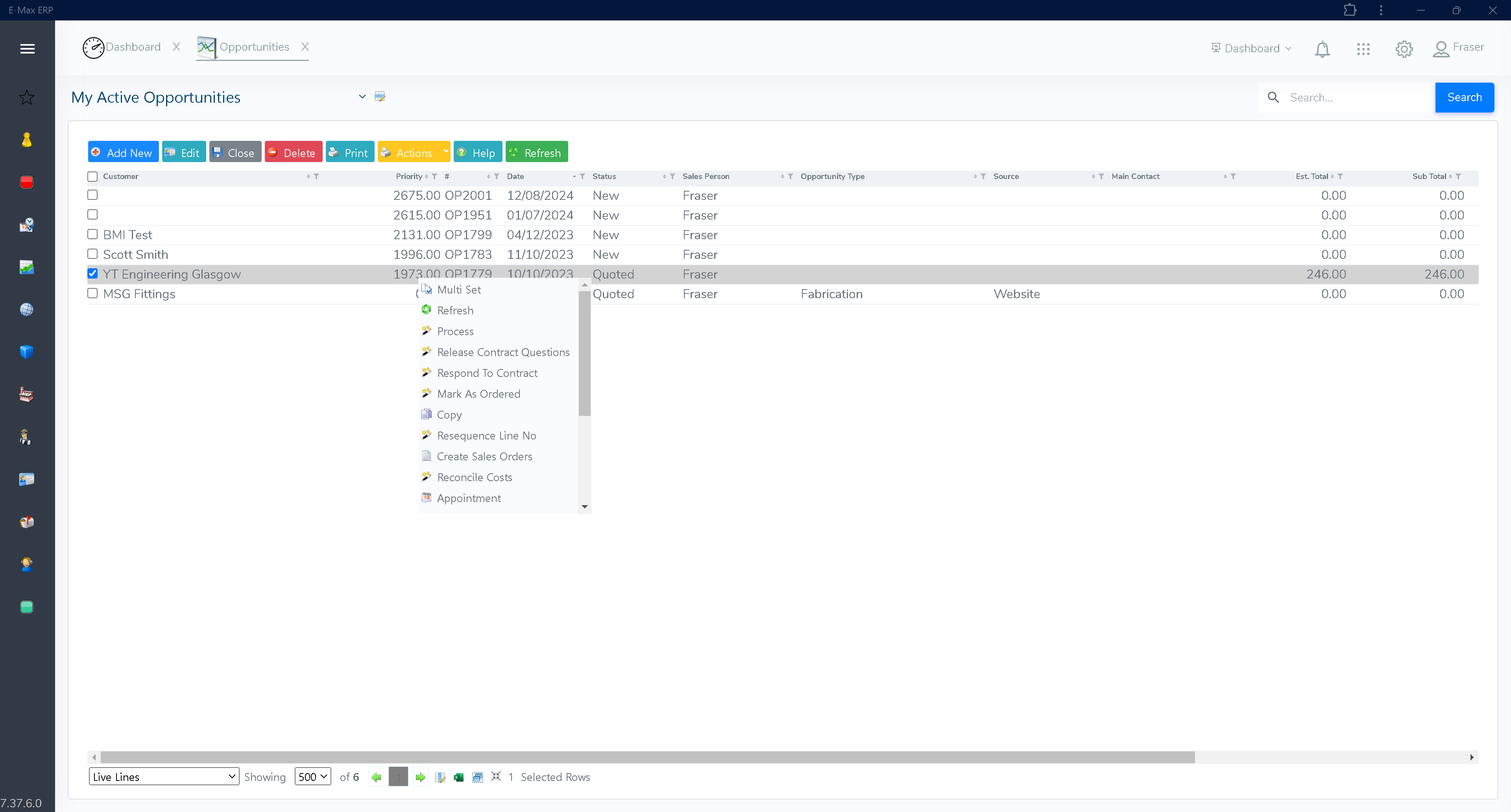

Instantly convert sales quotes to orders, raise purchase orders from works orders and create production schedules. By integrating sales, purchasing, inventory and production, jobs flow seamlessly through the system without any duplication or manual error.Quick Quotes

Generate quick quotes for prospective or existing customers. Include images and descriptions in a clear easy to read format and send electronically in just a few clicks. Leverage the data within E-Max ERP to provide fast, accurate and efficient responses to RFQs and win more business.Optimise Your Routing

Specify the tasks or operations and resources required for each job and the order in which these should be performed. With E-Max ERP you can create multiple route versions and add clear instructions and operator instructions on each route. Easily copy standard operations and routes from other parts. Store template routes and add different operations when required. Tests can also be assigned behind operations. Calculate planned labour costs and track set up times and run times, including cycle quantities and cycle time.Comprehensive Quality System

Ensure your products meet specified standards. E-Max ERP handles inspections, testing and documents all results during the project, guaranteeing quality and durability. Material & test certificates can also be scanned in and printed with delivery notes.E-Max ERP Software

offers all of this and more:

.png)

.png)

.png)

.png)

.png)

.png)