Elevate Your Sales & Marketing Results

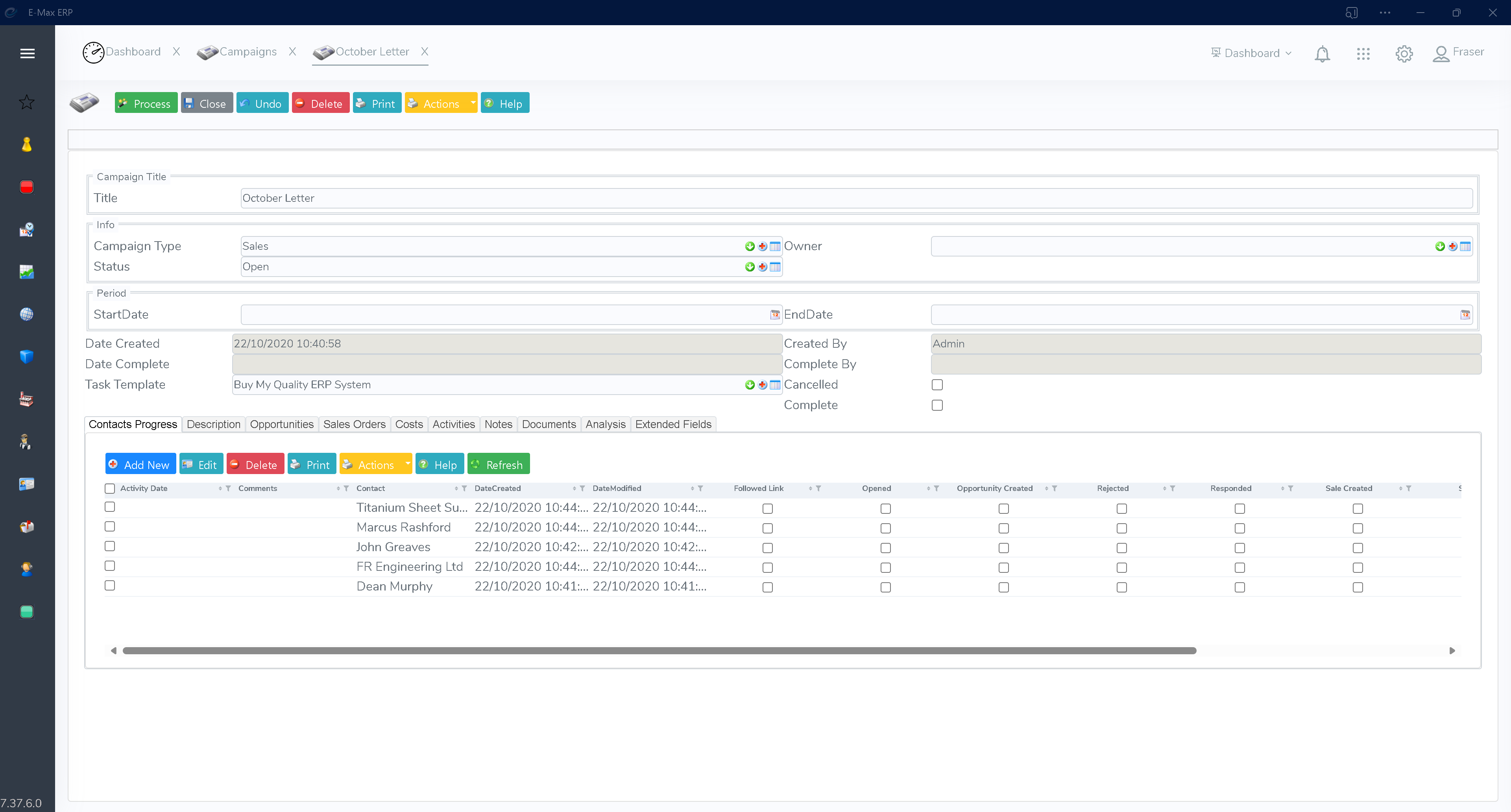

Use our powerful CRM features to drive your marketing activities and record campaign results. Efficiently manage your leads, track opportunities, and convert these into sales with E-Max workflows. Generate quick quotes and leverage the data in E-Max to provide fast, accurate and efficient responses to RFQs and manage existing customer relationships.Manage Multiple Customisation Options

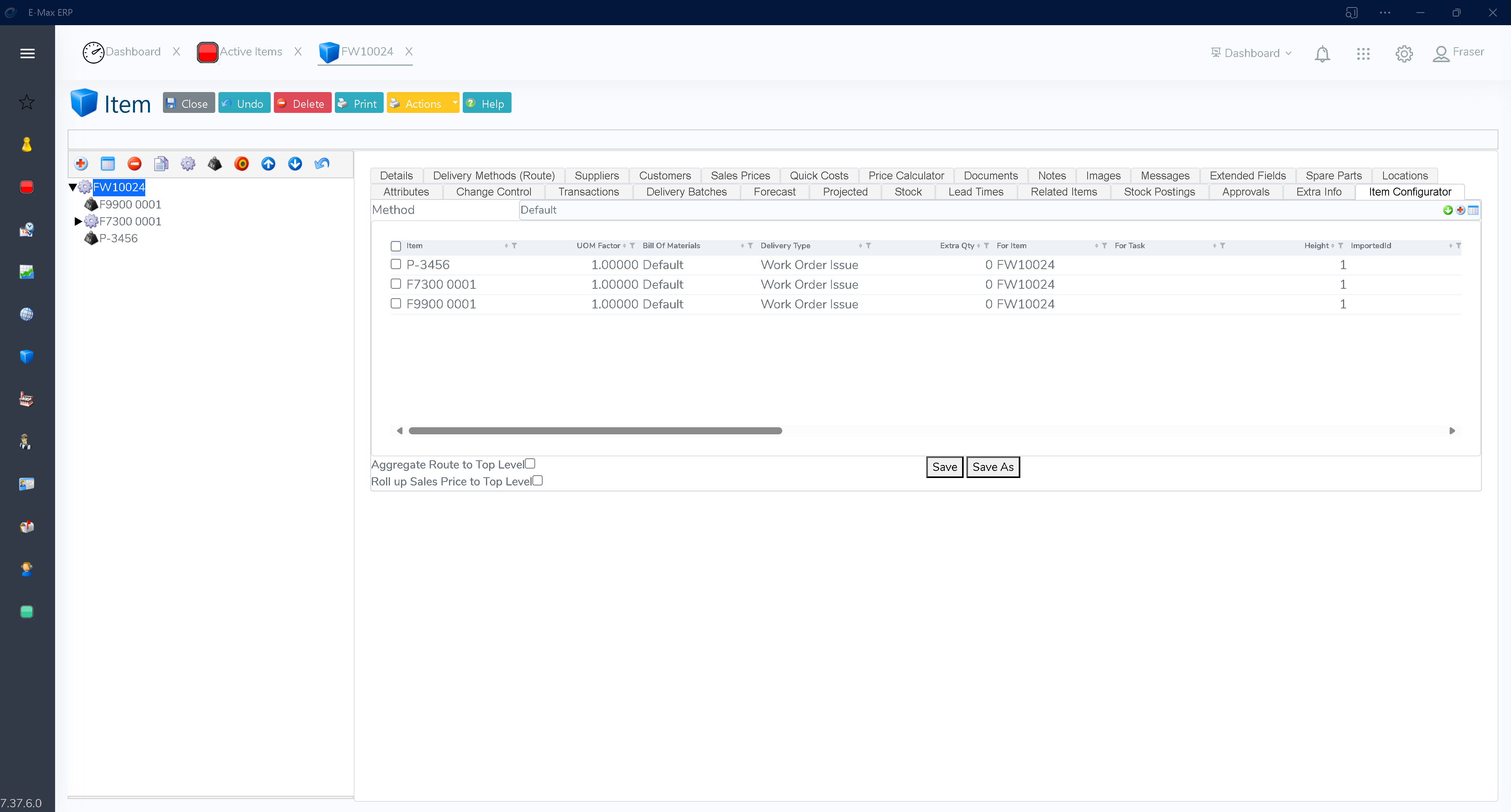

With our product configurator functionality, you can provide your customers with an almost unlimited range of options, yet quickly and easily cost these up.Quickly Raise Custom Quotes

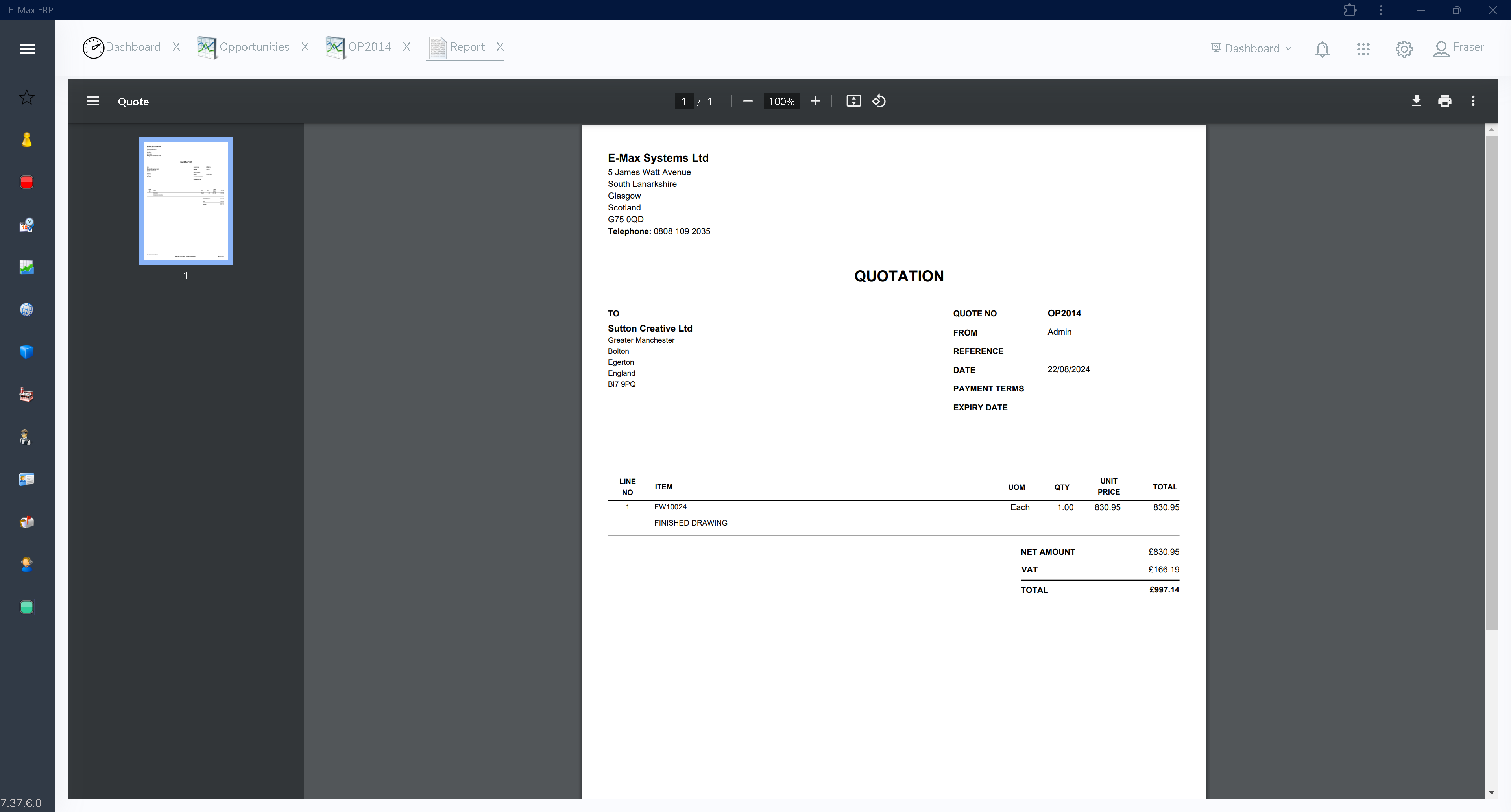

Generating attractive bespoke quotations is fast and simple in E-Max ERP. Include images and descriptions in a clear easy to read format and send electronically in just a few clicks.Item Variants

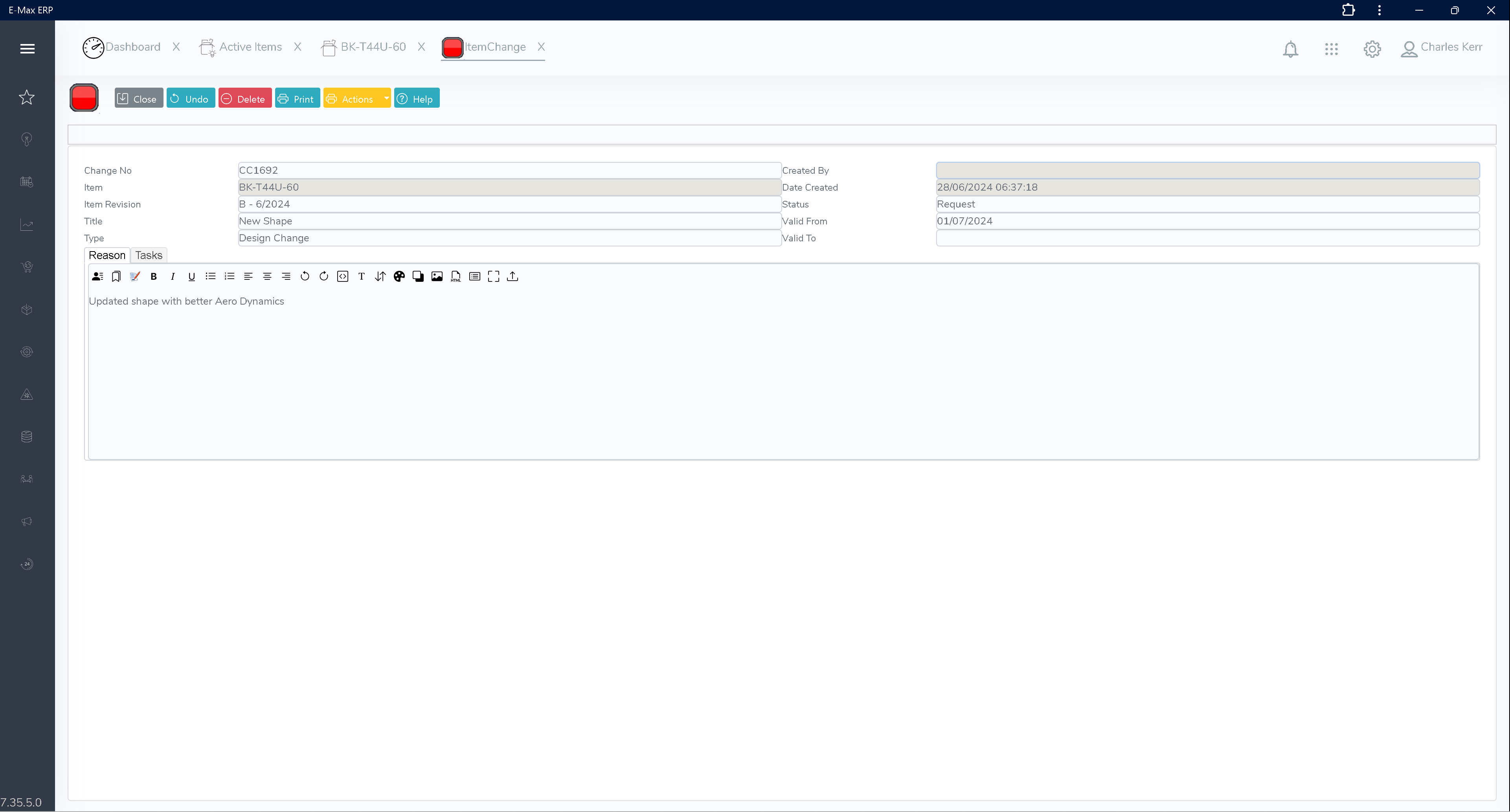

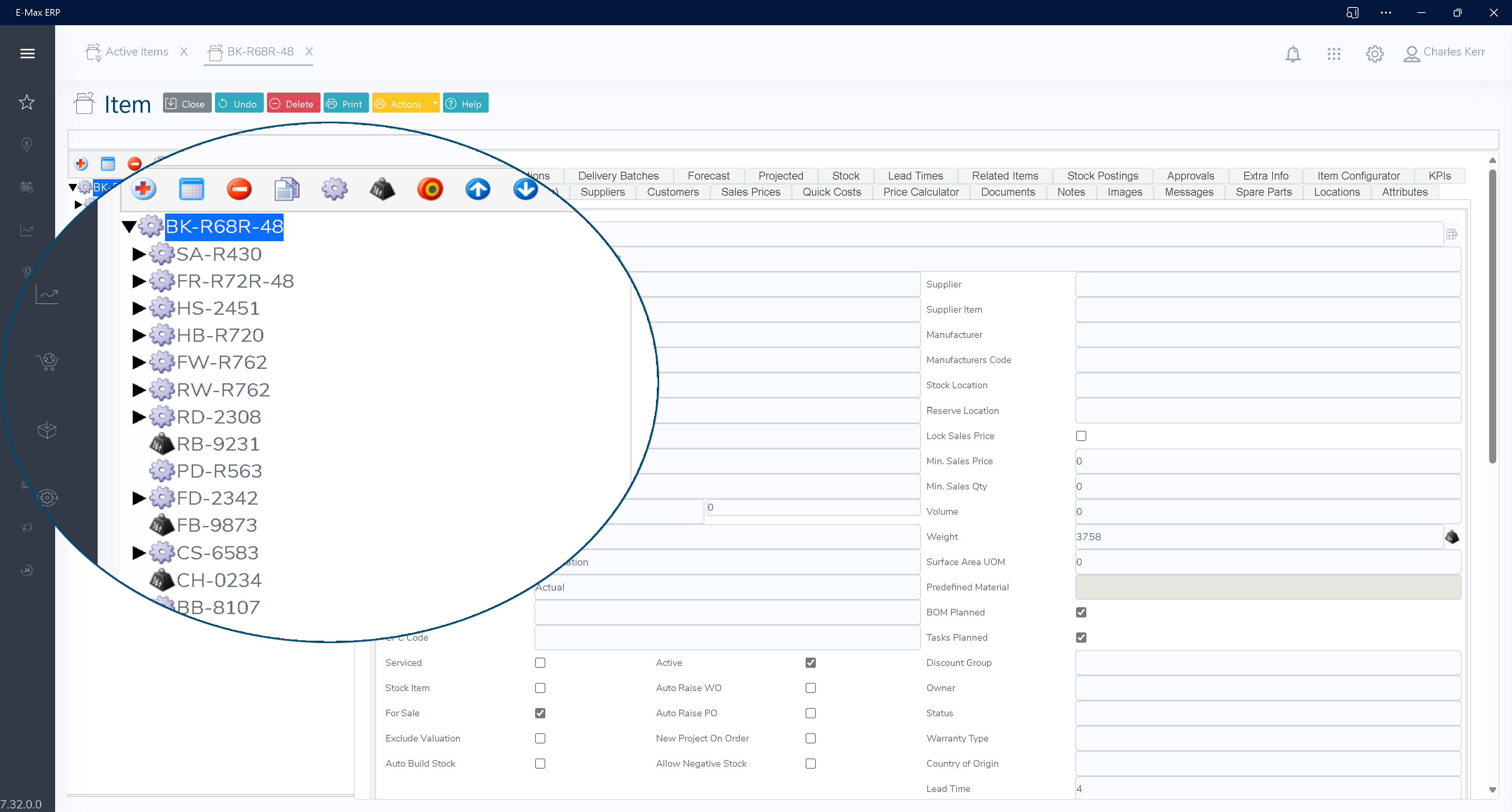

With E-Max ERP you can store multiple manufacturing versions and routes for an item. Ideal for companies that offer customisable or configurable products to meet diverse customer needs. E-Max also offers ECN and change control options.Bill of Materials (BOM)

E-Max’s bill of materials allows you to accurately define all the components, materials, parts, subassemblies and quantities required to manufacture a finished product. Starting with the finished product at the top, its hierarchical structure allows infinite multi-level BOMs of unlimited size. Save time by duplicating existing BOMs, use the tracking history to record revisions (ideal for audit purposes), and import BOMs from other software packages, including Excel and CAD packages. Included in E-Max ERP’s BOM is a standard item configurator.BOM Control

Manage every change or update to your BOM across components, sub-assemblies and materials with E-Max’s BOM control. Once approved, our Version Control records and stores the full history of BOM revisions.Inventory Tracking

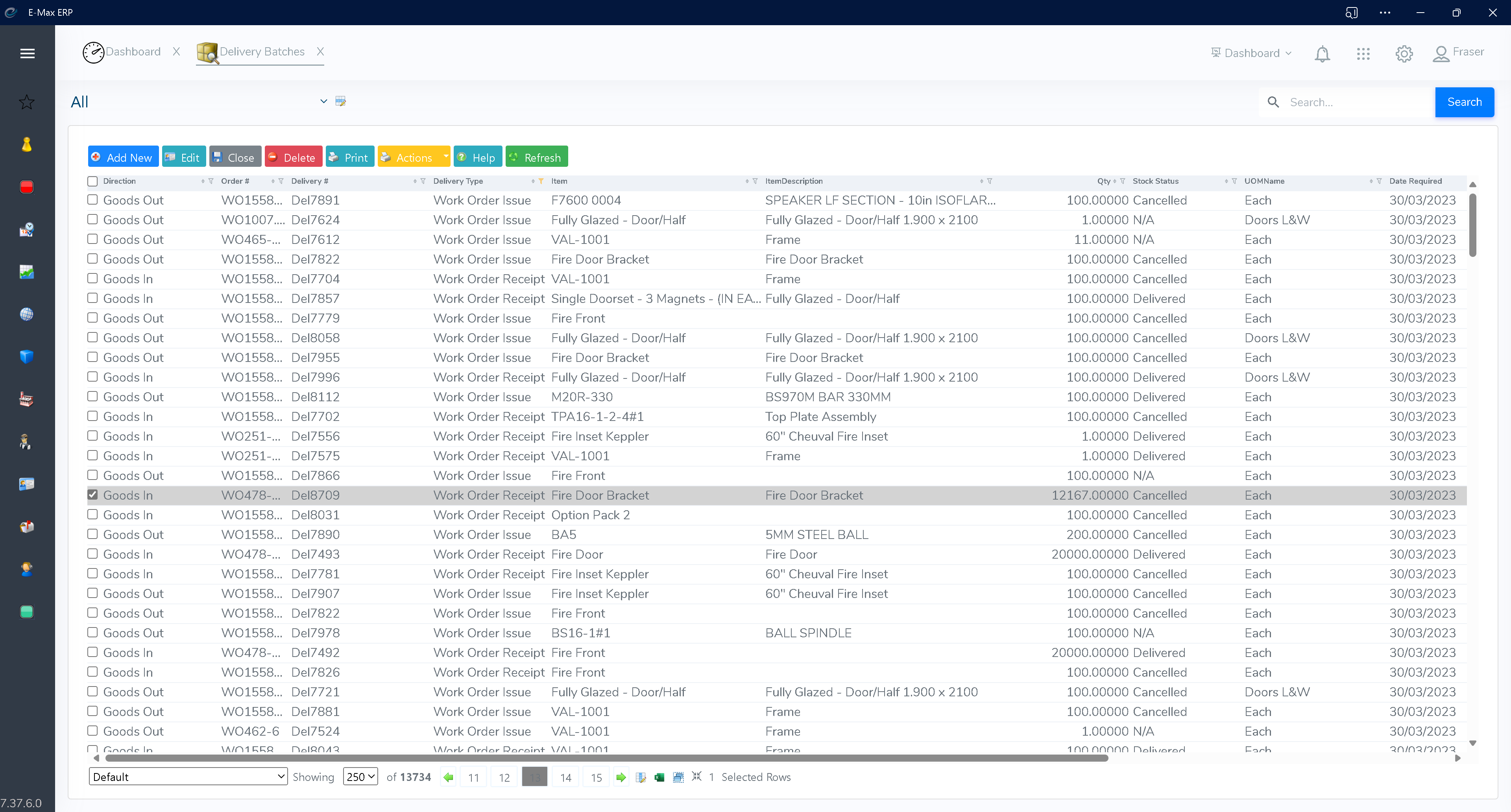

Monitor the flow of goods in and out of the warehouse with E-Max’s stock control system. Track what materials you have, the quantity of each, location within the warehouse, and any changes in stock levels due to sales, returns, or new arrivals, all in real time and visible from any area of E-Max ERP.Kitting

Streamline your picking and packing process further by creating kits. Use E-Max’s BOM to specify components and quantities and store them in easily accessible locations under a separate SKU or item number.Free Issue

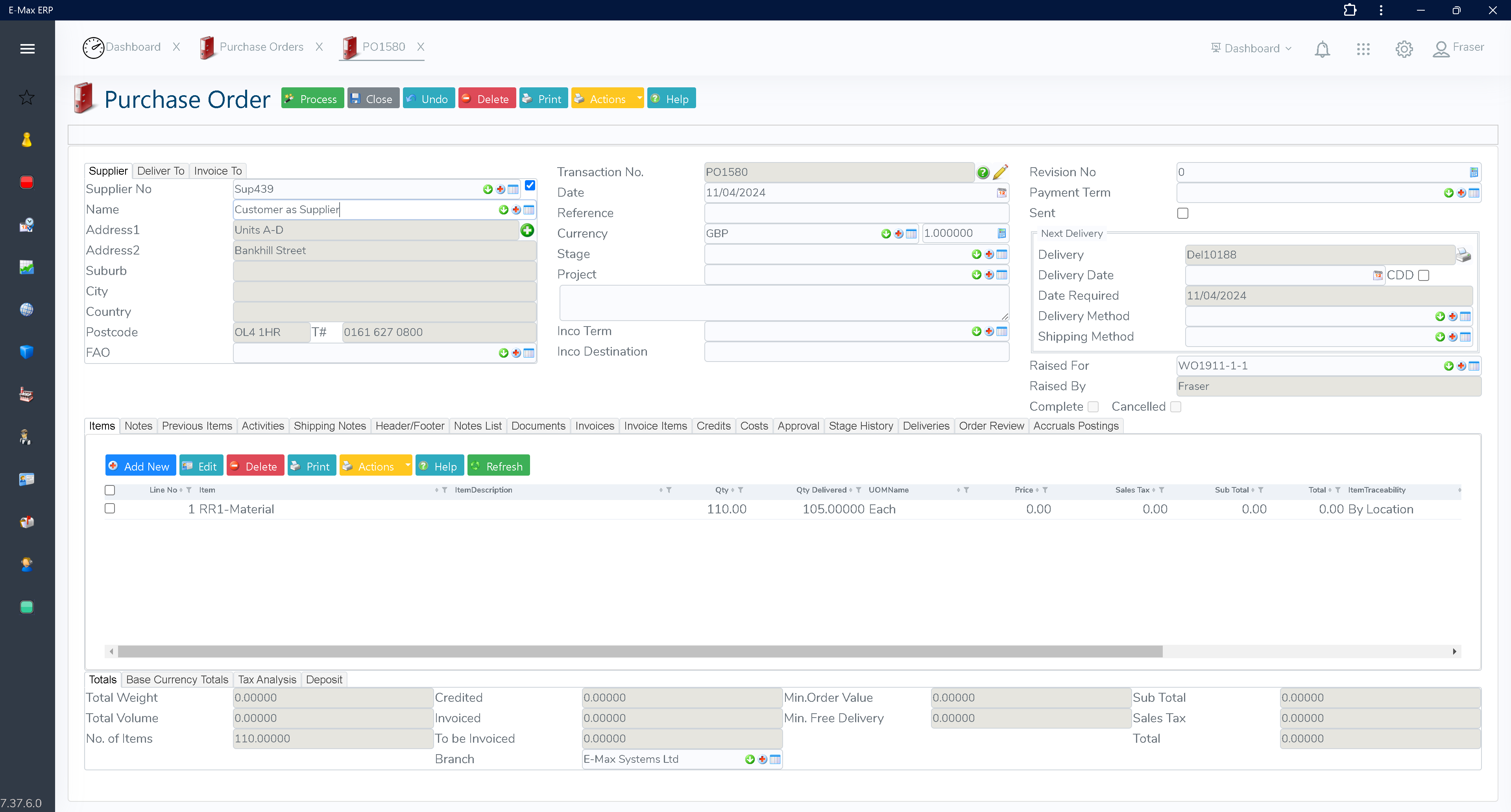

When customers need you to use materials provided by them, your ERP system needs to be capable of accounting for this. E-Max ERP allows you to raise a PO to your customer for free issue material at zero cost, pulling it into the system and logistically treating this like every other material requirement.Maximise Your Resources

Take your MRP to the next level with E-Max ERP as you plan, monitor and organise your resources to meet customer deadlines. Schedule activities, factoring in availability of labour, including specific skill levels, machinery, tools, and workstations, to create optimal production plans. In addition to daily, weekly, and monthly planning, our MRP functionality can be used for long term planning and forecasting and is compatible with cost saving strategies like Just In Time (JIT) and Kaizen.Used and Trusted by

View Key Analytics and Reporting for Vehicle Conversion Businesses

See the KPIs that matter to you on E-Max's customisable dashboards. Track work orders, stock levels, quality, production targets, waste and costs and understand exactly how your vehicle conversion business is performing.Establish Standard Operating Procedures

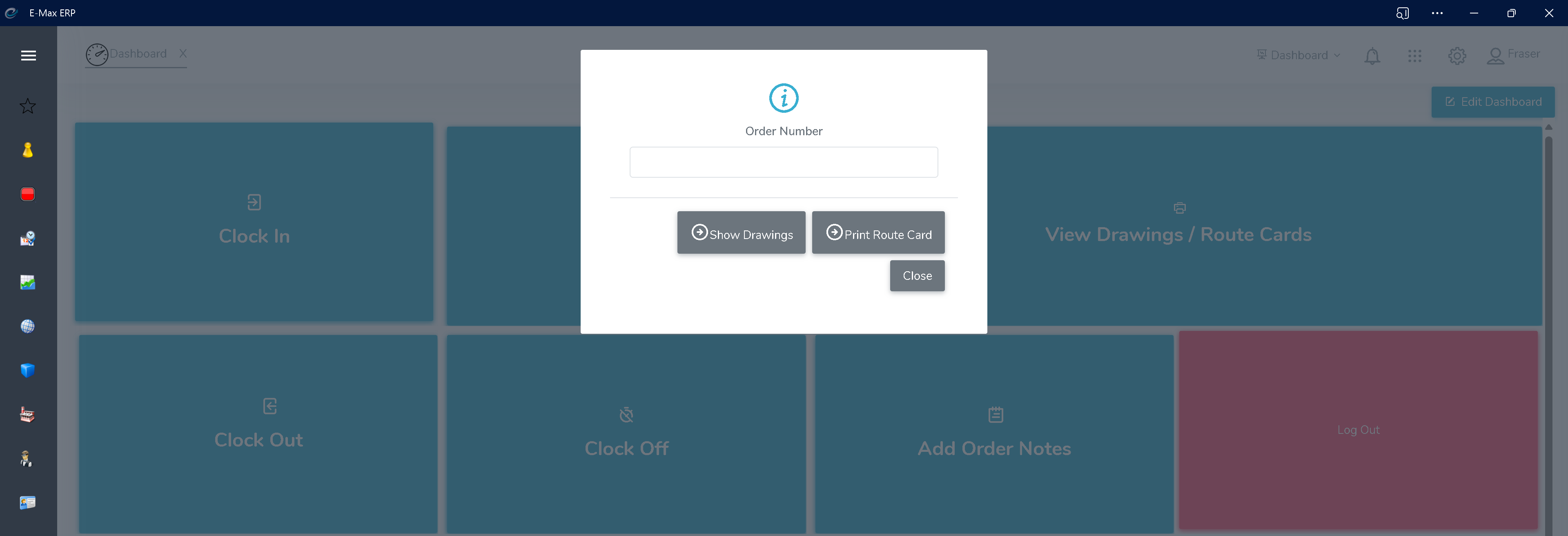

With E-Max ERP’s integrated document management feature, defining and adhering to SOPs is straightforward. All employees, from shop floor to front office, can be granted access to relevant documents, removing ambiguity, and improving compliance and quality output.View Drawings & Instructions

Any drawings or instructions attached to a job are pulled into the SFDC directly with the work order. Provided the terminal, ie tablet or PC, has the relevant document viewer installed, any shop floor operative can access these documents, list of instructions, etc, and easily read these on the terminal, removing the need for paperwork on the shop floor. Route cards can also be accessed this way and tasks or operations clocked on to from the terminal. If there is a requirement to print or email information, ie a list of time bookings, this can be done from within the SFDC, making it an ideal tool for a field service environment.One System, One Truth

Move away from multiple spreadsheets and other time-consuming and error-prone methods by bringing all your data into one system. With all the information you need, when you need, you can confidently make the right decisions for your business and keep your business growing.E-Max ERP Software

offers all of this and more:

.png)

.png)

.png)

.png)

.png)

.png)