Quick Quotes

Generate quick quotes for prospective or existing customers. Include images and descriptions in a clear easy to read format and send electronically in just a few clicks. Leverage the data within E-Max ERP to provide fast, accurate and efficient responses to RFQs and win more business.Shopfloor Management

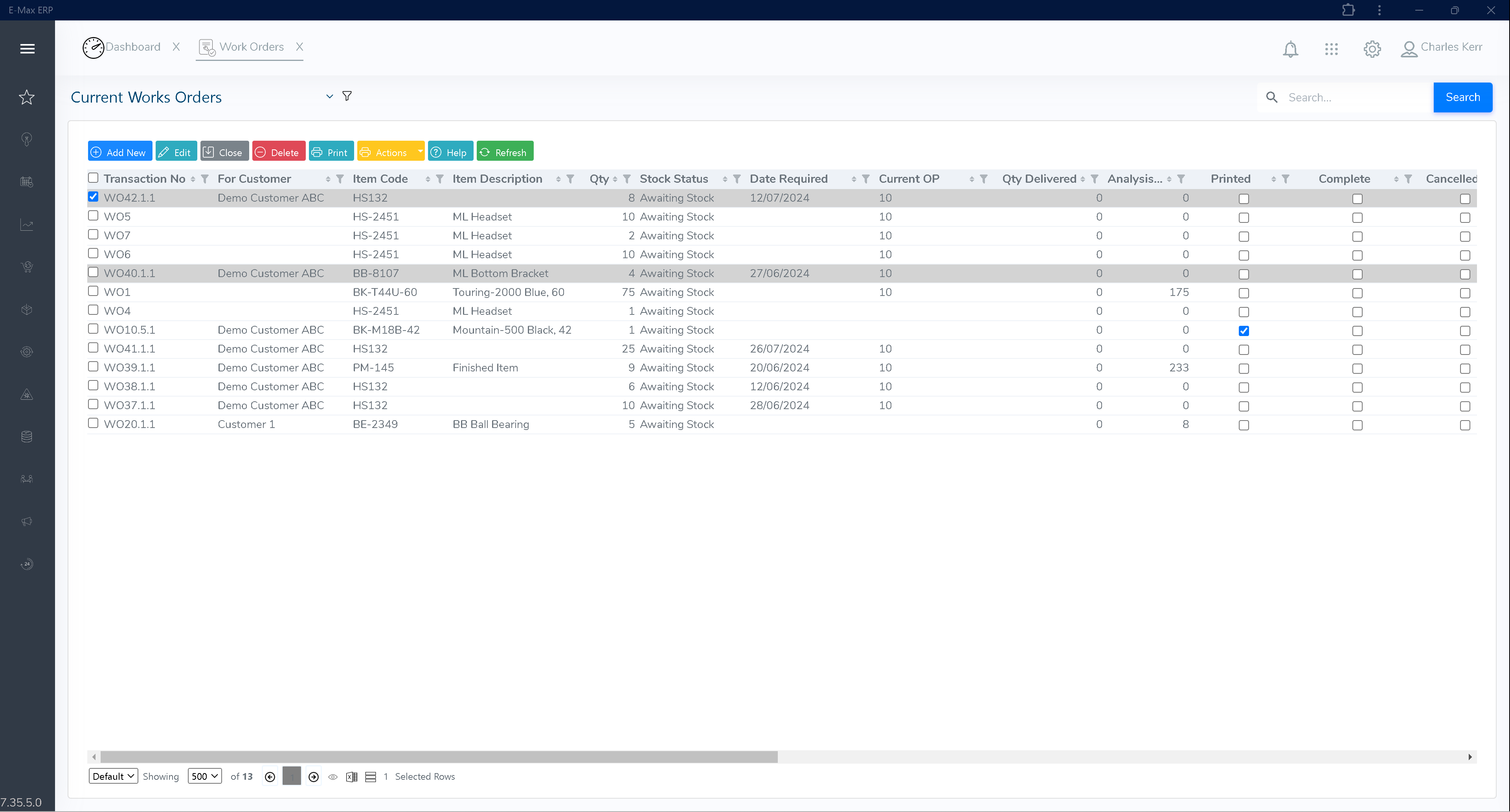

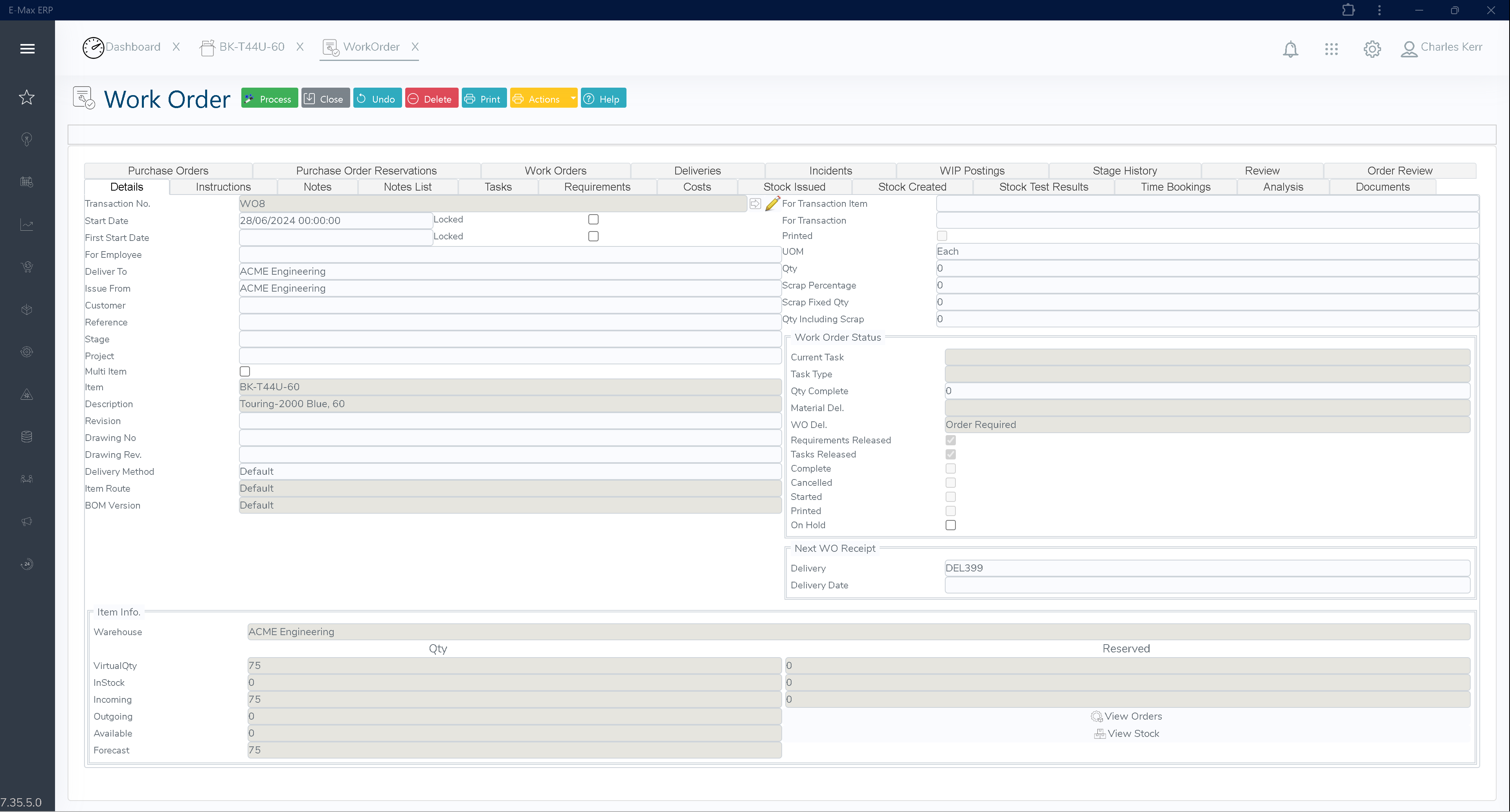

Schedule and monitor your production activities on the shop floor. E-Max ERP tracks the progress of work orders, manages work-in-progress, and ensures that production processes are performed efficiently.Works Order Management

Generate works orders in a single click with E-Max ERP and keep your production moving. Guide your production team, coordinate your resources and ensure every job is manufactured to a quality standard and schedule. E-Max ERP supports multi-item works orders, allowing for nesting and by-products being returned to stock.Full Traceability

E-Max ERP tracks materials in real time across your operations, not just in the warehouse. Track by batch, serial or lot numbers, or by date, including First In First Out (FIFO), Last In First Out (LIFO), and Use By.Identify Your Available Capacity

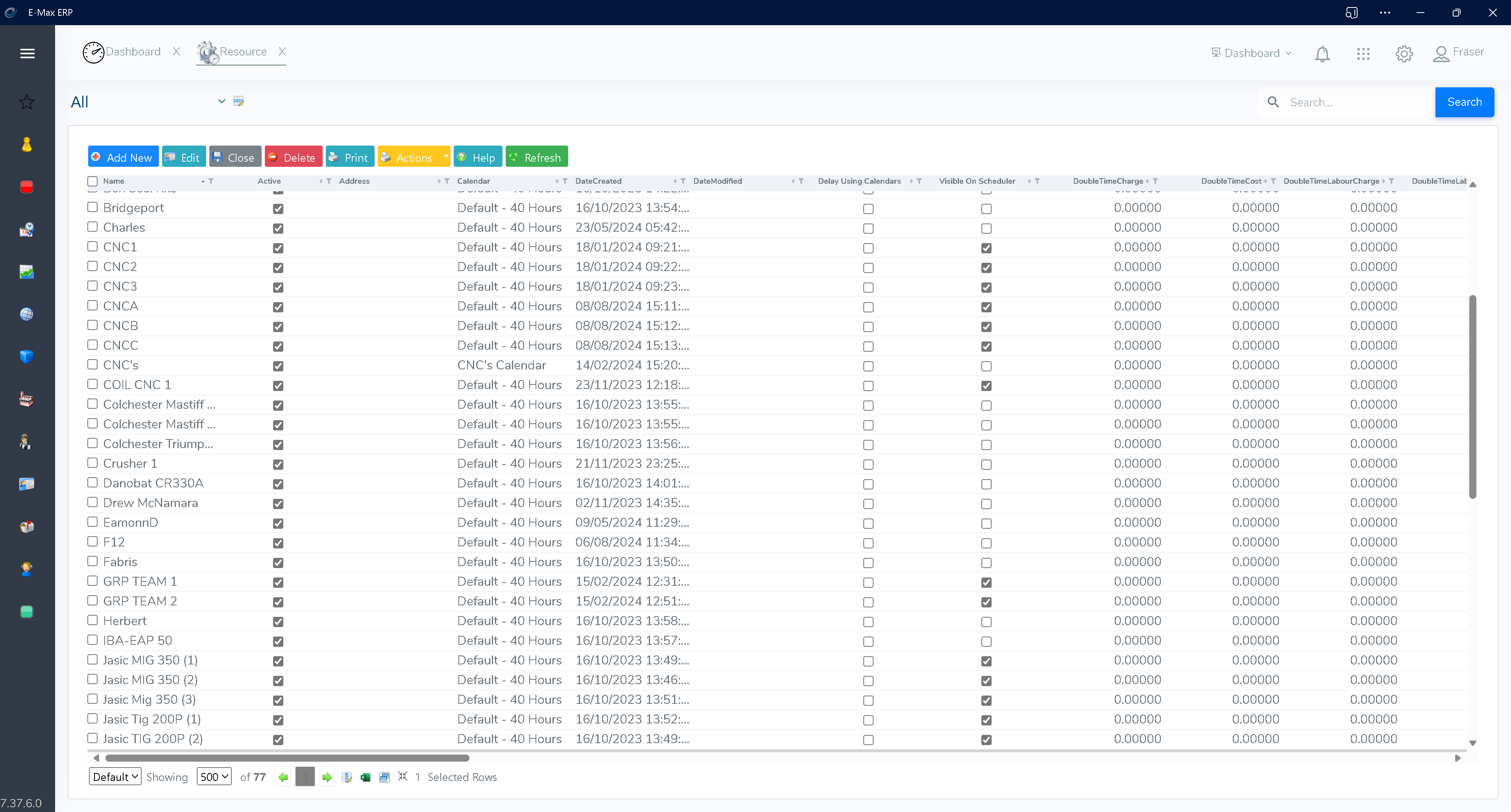

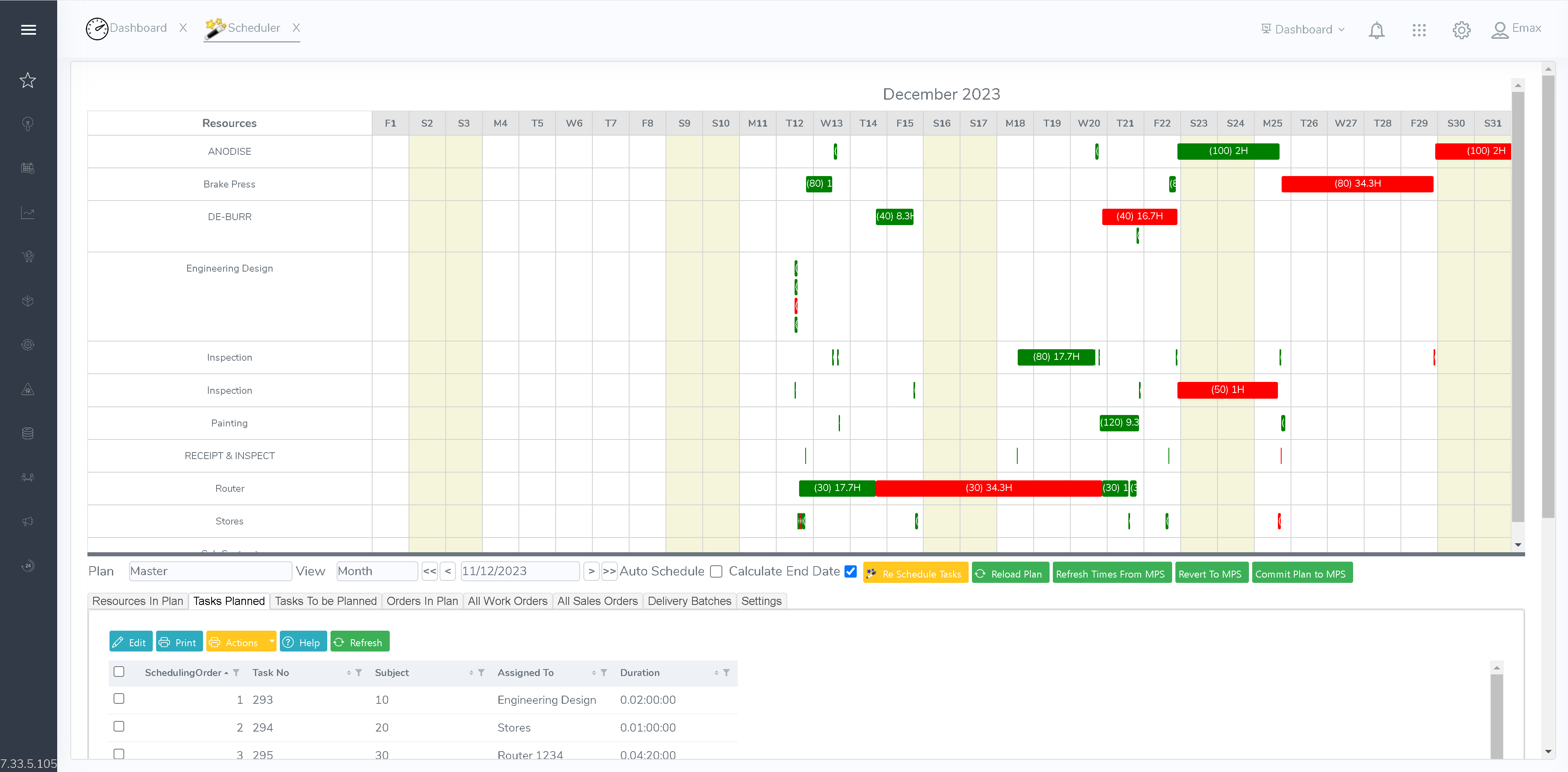

Maximise your machine usage by understanding when your machines are running operations or not, allowing you to take on additional work without increasing capacity.Utilise Finite Scheduling

Set your parameters on each available resource in E-Max ERP to ensure no over-booking. The system’s scheduling engine creates a plan based on the most efficient delivery of jobs using all the information contained within E-Max ERP, including delivery dates and available resource. Our drag and drop functionality can also be used to fine tune planned schedules, for specific occasions when experience and knowledge come into play, ie consolidated set-ups.Key Analytics and Reporting for Precision Engineering

View the KPIs that matter to you on E-Max's customisable dashboards. Track work orders, stock levels, quality, production targets, waste and costs and understand exactly how your precision engineering business is performing.Manage Scrap

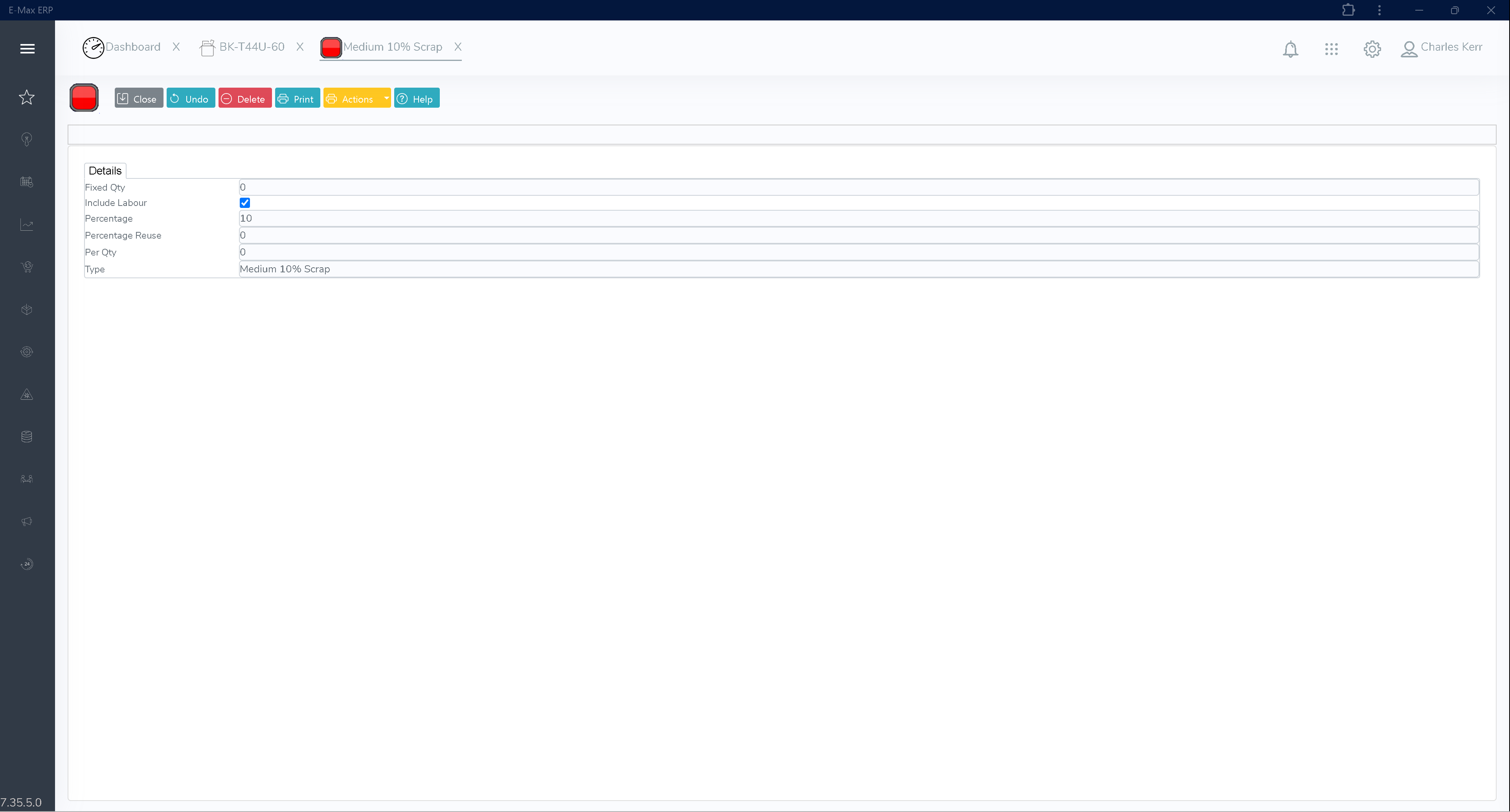

Avoid material shortages and account for all material costs by recording scrap or wastage information. E-Max ERP allows you to apply a fixed quantity and/or percentage to all items, either purchased or manufactured, for accurate materials management. Fixed and percentage scrap is also handled at every level in our BOM.Understand Your Production Costs

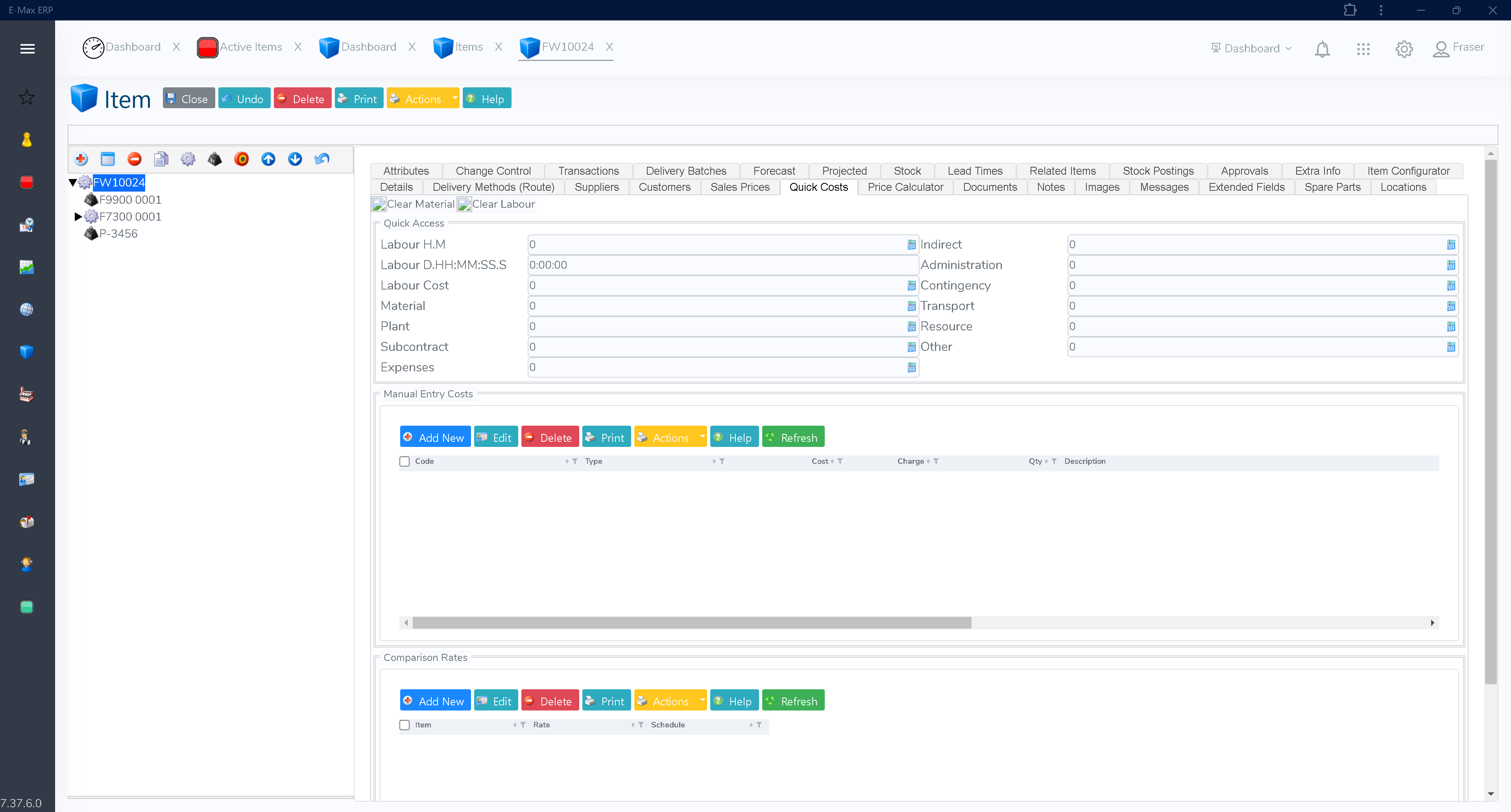

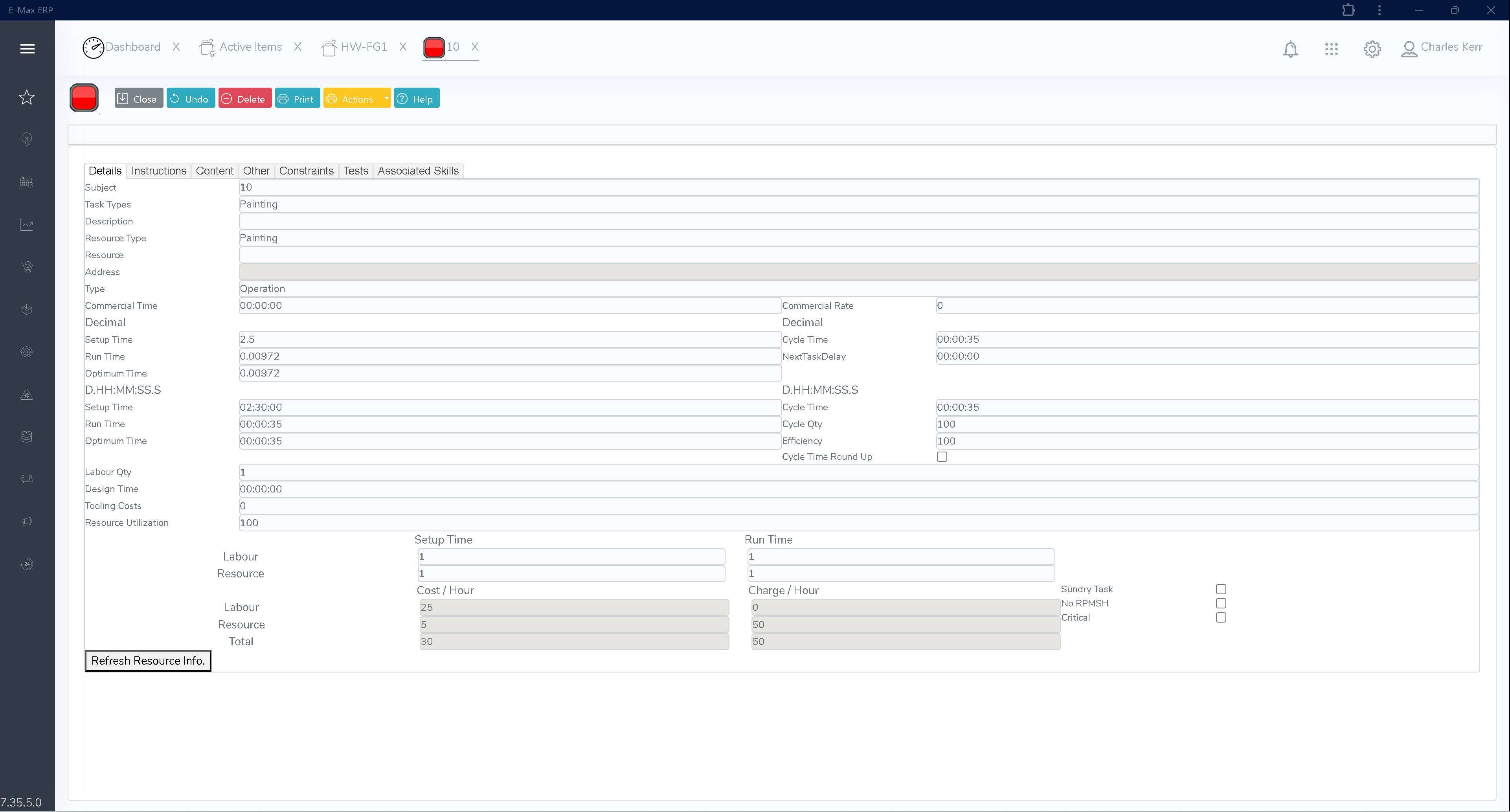

Get clear visibility over planned and actual production costs with E-Max ERP. Calculate labour costs and track set up times and run times, including cycle quantities and cycle time. Cycle times can be set as decimals of days, hours, minutes and even points of a second to allow precise and accurate costing. Track and cost any assembly work as it happens. Material costs are allocated to each job.Bill of Materials (BOM)

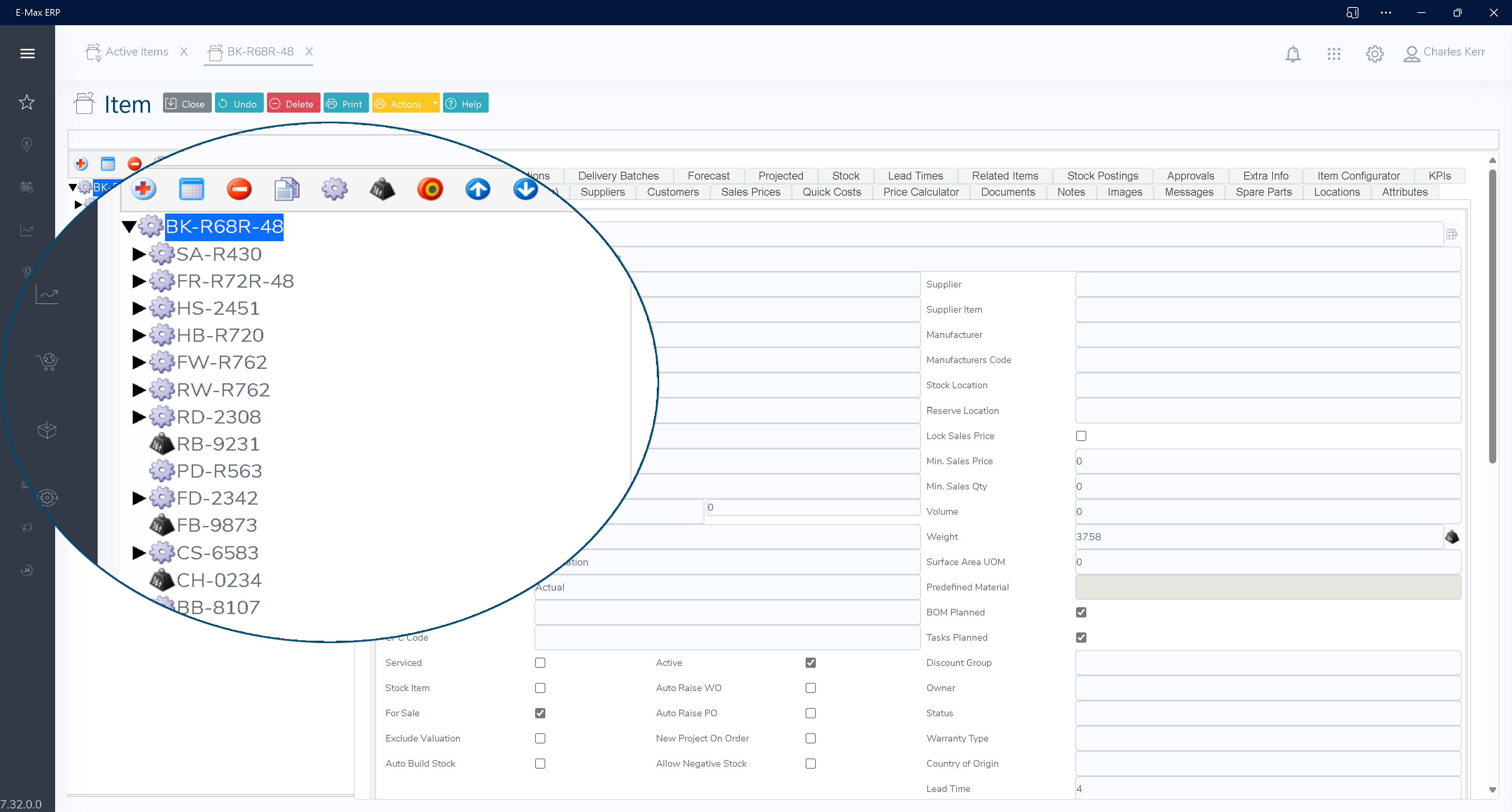

E-Max’s bill of materials allows you to accurately define all the components, materials, parts, subassemblies and quantities required to manufacture a finished product. Starting with the finished product at the top, its hierarchical structure allows infinite multi-level BOMs of unlimited size. Save time by duplicating existing BOMs, use the tracking history to record revisions (ideal for audit purposes), and import BOMs from other software packages, including Excel and CAD packages. Included in E-Max ERP’s BOM is a standard item configurator.Item Revisions and Version Control

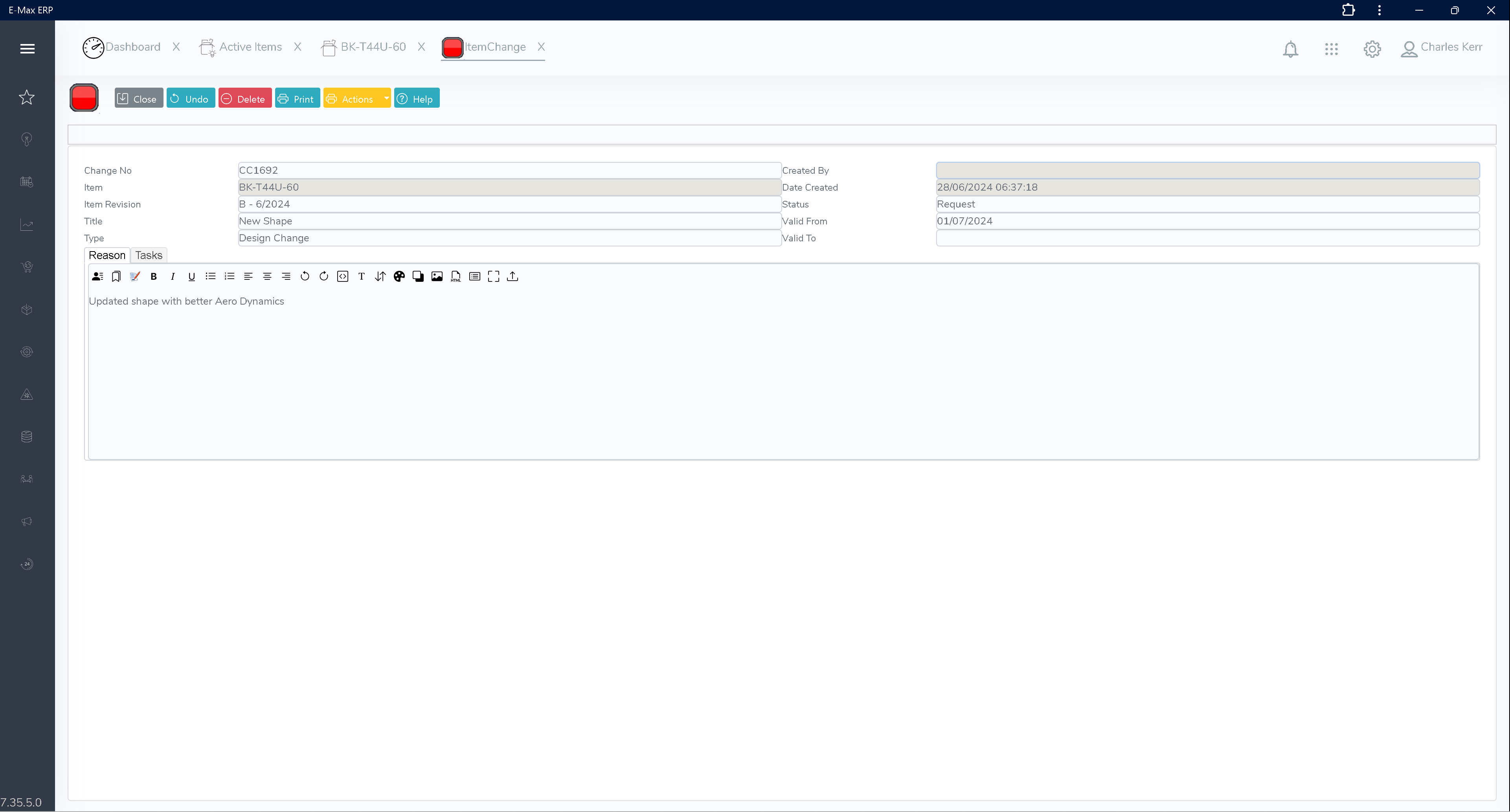

Achieve clear visibility and control of each different version of a BOM or route. As part of E-Max’s product lifecycle management, all revisions are tracked, with the current version being stored on the item or part master.Item Variants

With E-Max ERP you can store multiple manufacturing versions and routes for an item. Ideal for companies that offer customisable or configurable products to meet diverse customer needs. E-Max also offers ECN and change control options.Manage Subcontract Work

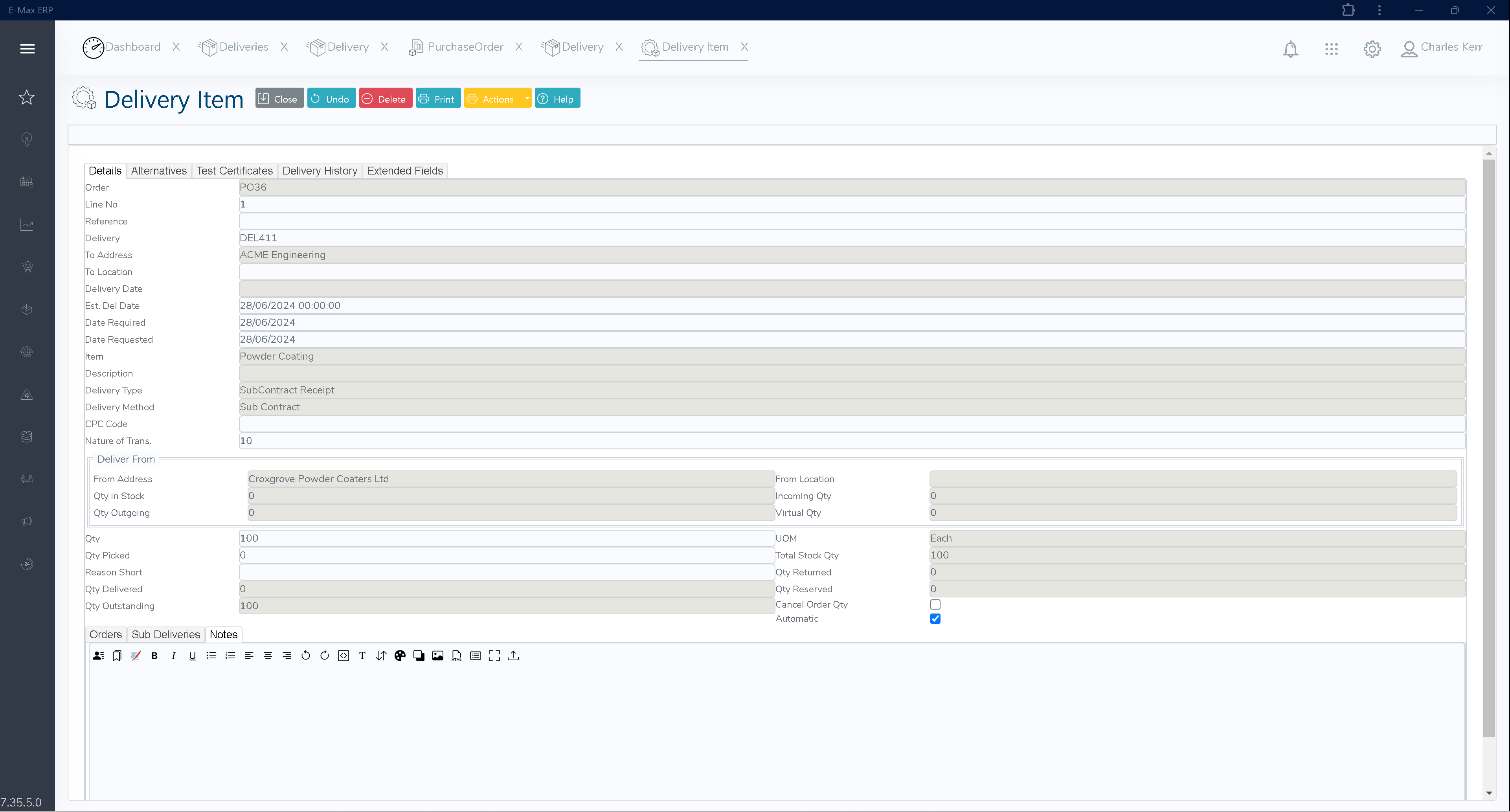

Get clear visibility of your subcontract costs and allocate these costs to the correct job.Multiple Unit of Measure (UOM) & Conversions

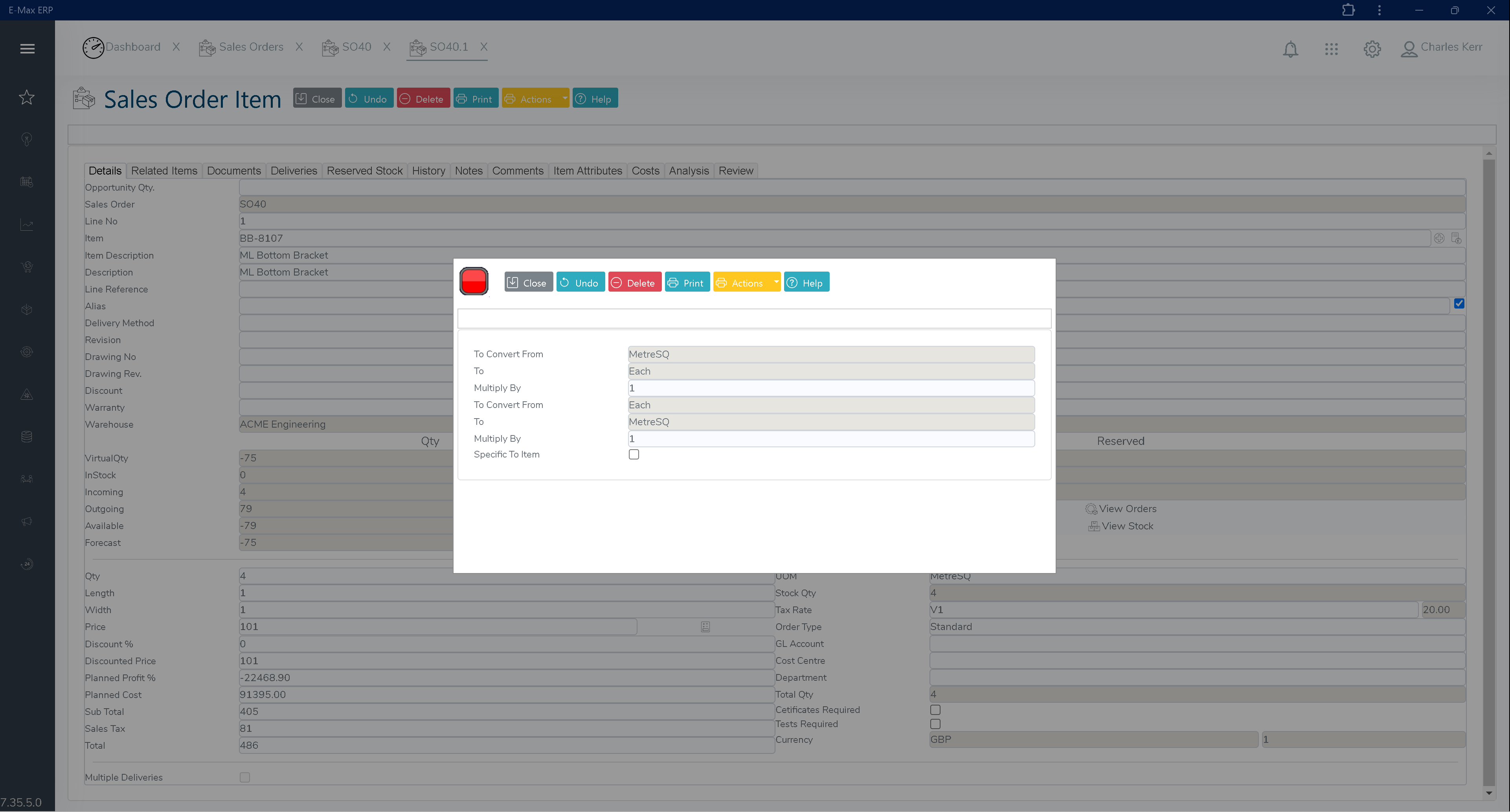

E-Max ERP gives you the ability to measure materials precisely, based on your preferences. Stay in control of various units of measurement for your inventory. Establish conversion ratios directly within the system, ensuring seamless management of sales, purchases, and stock transactions. The system will seamlessly manage all conversions on your behalf.Used and Trusted by Precision Engineers

E-Max ERP Software

offers all of this and more:

.png)

.png)

.png)

.png)