Manage your Production

Get real-time visibility into every step of the production process, from sales order to work order processing, routing and scheduling, order fulfillment, and product costing. With this information you can optimise your production processes, reduce lead times, and improve your overall production efficiency.Understand & Control Your Production Costs

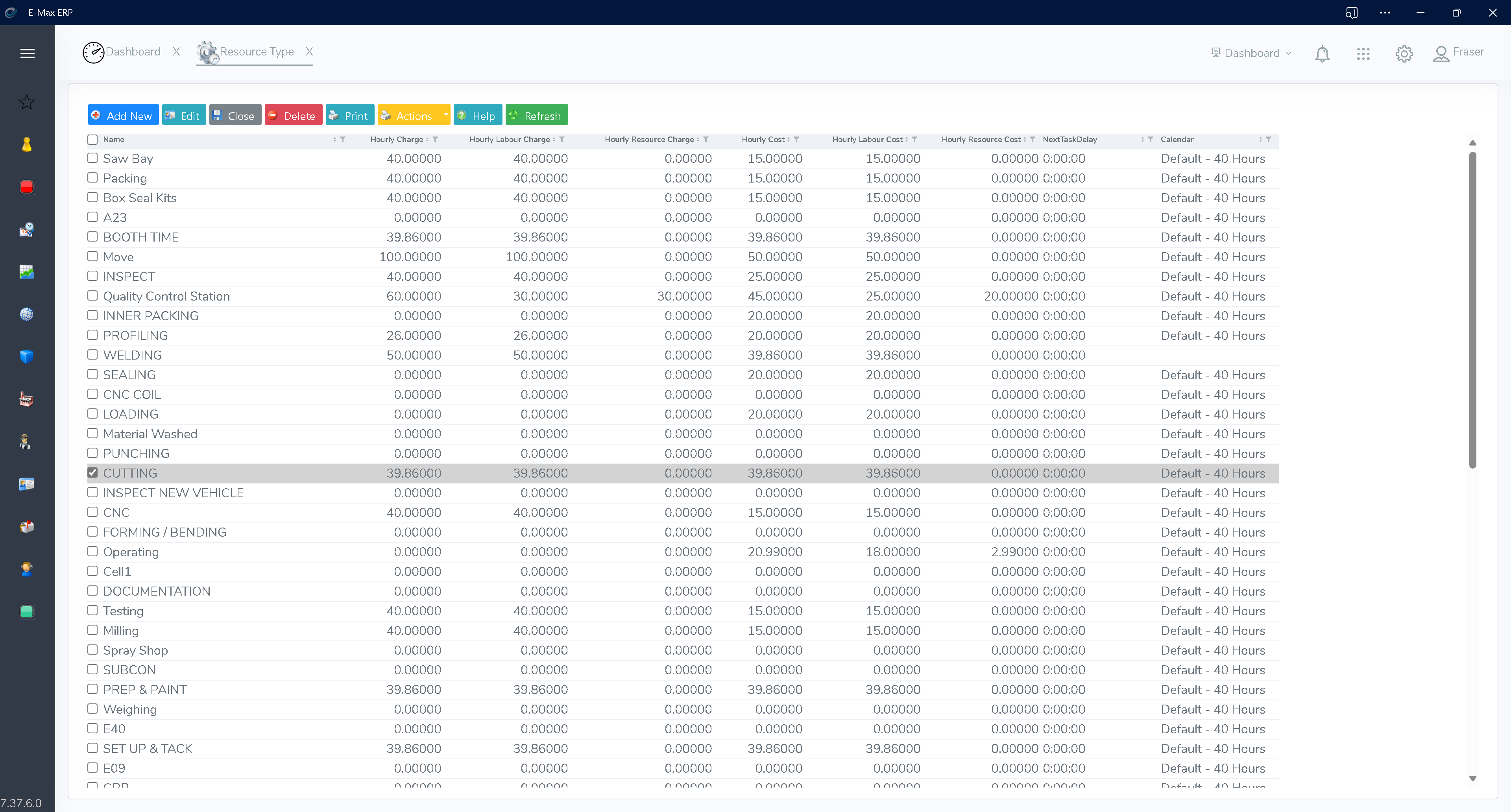

Calculate planned costs and track your actual production costs with E-Max ERP to identify any variances. Calculate labour costs and track set up times and run times, including cycle quantities and cycle time. Cycle times can be set as decimals of days, hours, minutes and even points of a second to allow precise and accurate costing. Track and cost any assembly work as it happens. Material costs are allocated to each job.Stock Management

Accurately track inventory levels and ensure you have the necessary materials to complete each job. The most cost-effective materials for each job are easily identified. With E-Max you can also minimise waste by optimising use of raw materials, saving time, material, and cost by using the use the same piece of raw material across different jobs. These split costs can then be allocated to the relevant job. Our Warehouse Management ensures that stock can be easily identified and located.Manage Scrap & Reduce Wastage

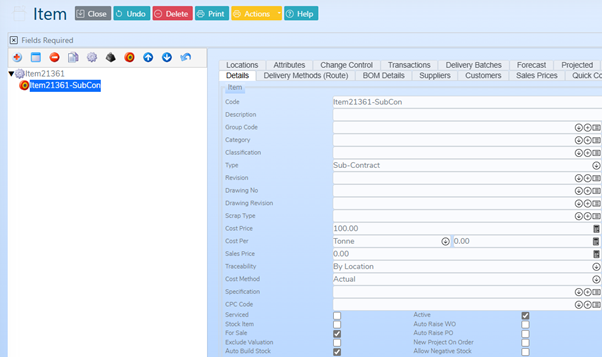

Avoid material shortages and account for all material costs by recording scrap or wastage information. E-Max ERP allows you to apply a fixed quantity and/or percentage to all items, either purchased or manufactured, for accurate materials management. Fixed and percentage scrap is also handled at every level in our BOM. Return unused materials into stock and re-use at a later stage.Calculate Quality Costs

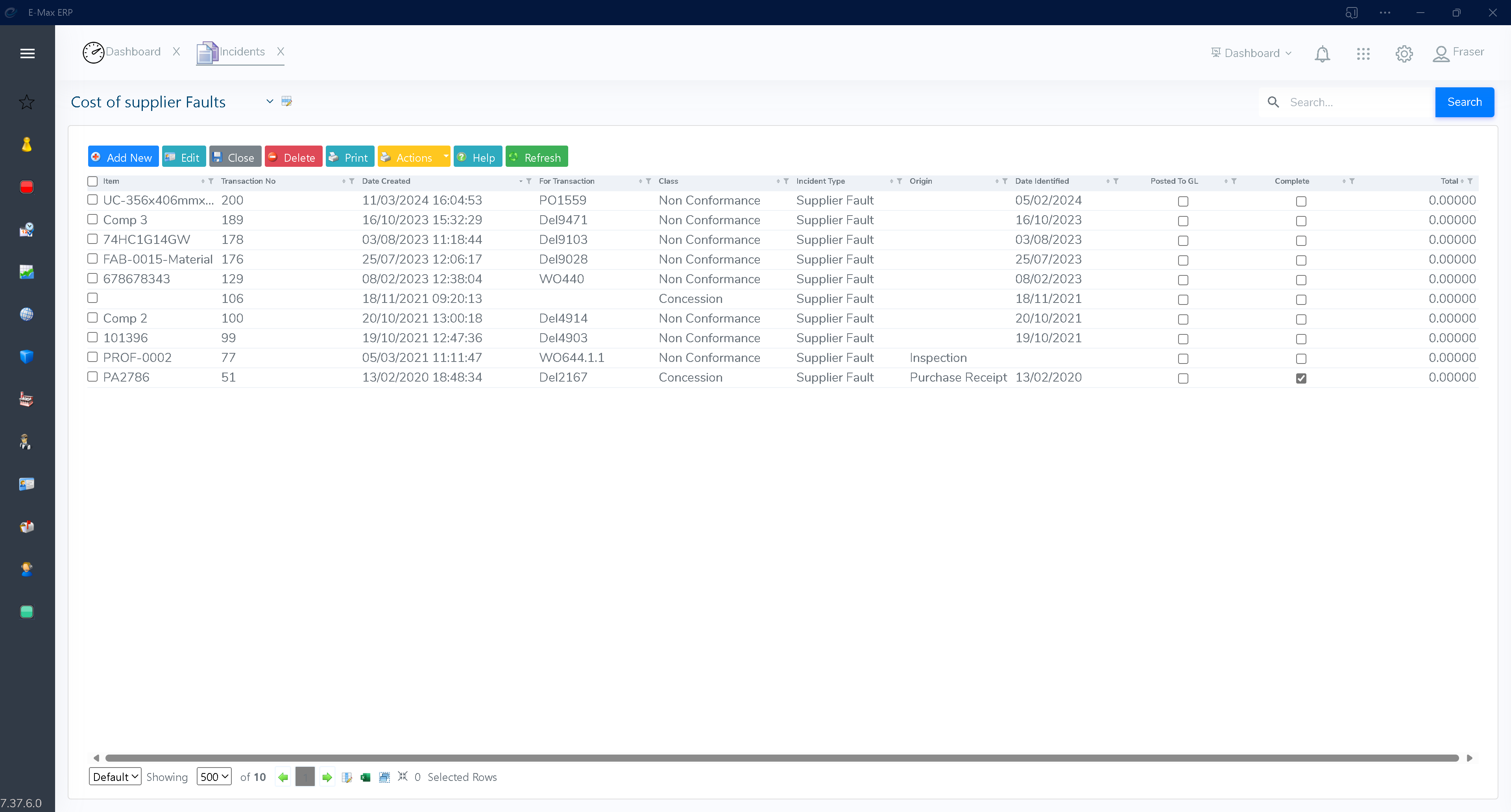

Track the cost of quality and make informed decisions based on real time data. Our reporting makes it easy to identify how much quality is costing you, ie in terms of returns, machine breakdowns, sub-standard products, etc. With E-Max ERP, you can perform a range of testing measures, including random testing, first off testing, etc.Backflushing

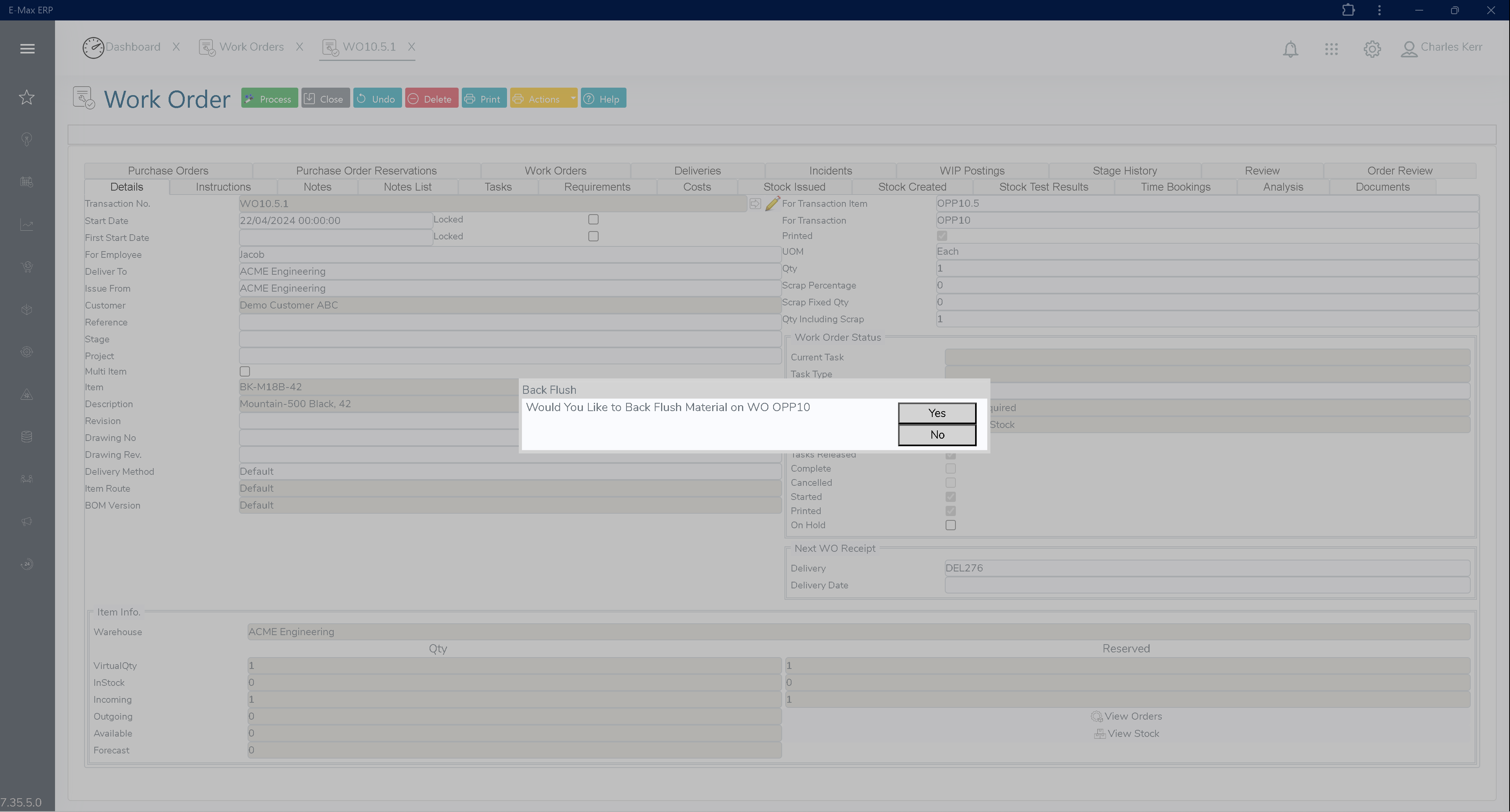

If the exact quantities required for a job are not known, E-Max allows the materials or items used in that job to be removed from stock, using the pre-defined bill of materials (BOM), after production is completed or the finished item(s) receipted into stock.Bill of Materials (BOM)

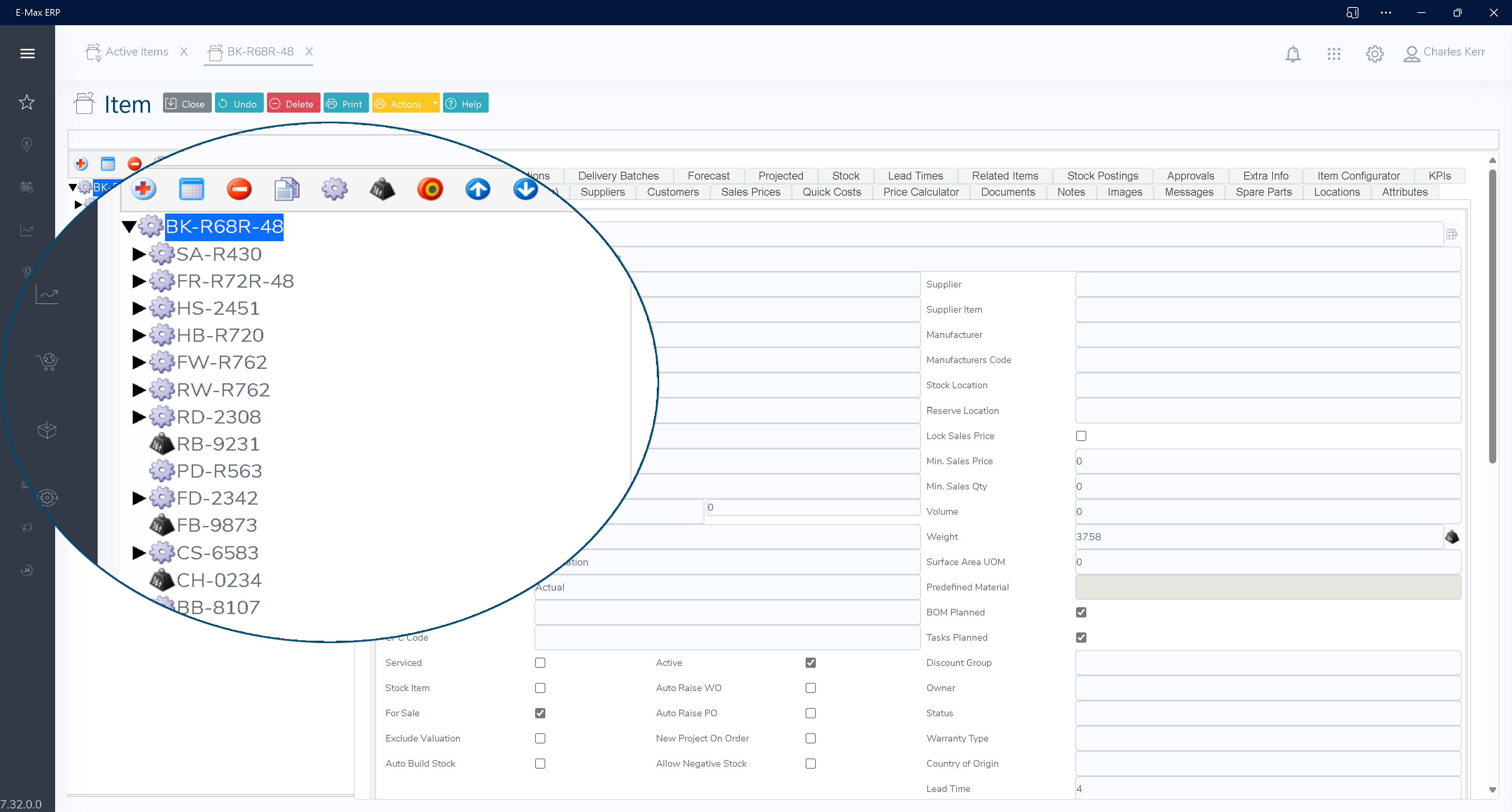

E-Max’s bill of materials allows you to accurately define all the components, materials, parts, subassemblies and quantities required to manufacture a finished product. Starting with the finished product at the top, its hierarchical structure allows infinite multi-level BOMs of unlimited size. Save time by duplicating existing BOMs, use the tracking history to record revisions (ideal for audit purposes), and import BOMs from other software packages, including Excel and CAD packages. Included in E-Max ERP’s BOM is a standard item configurator.Works Order Management

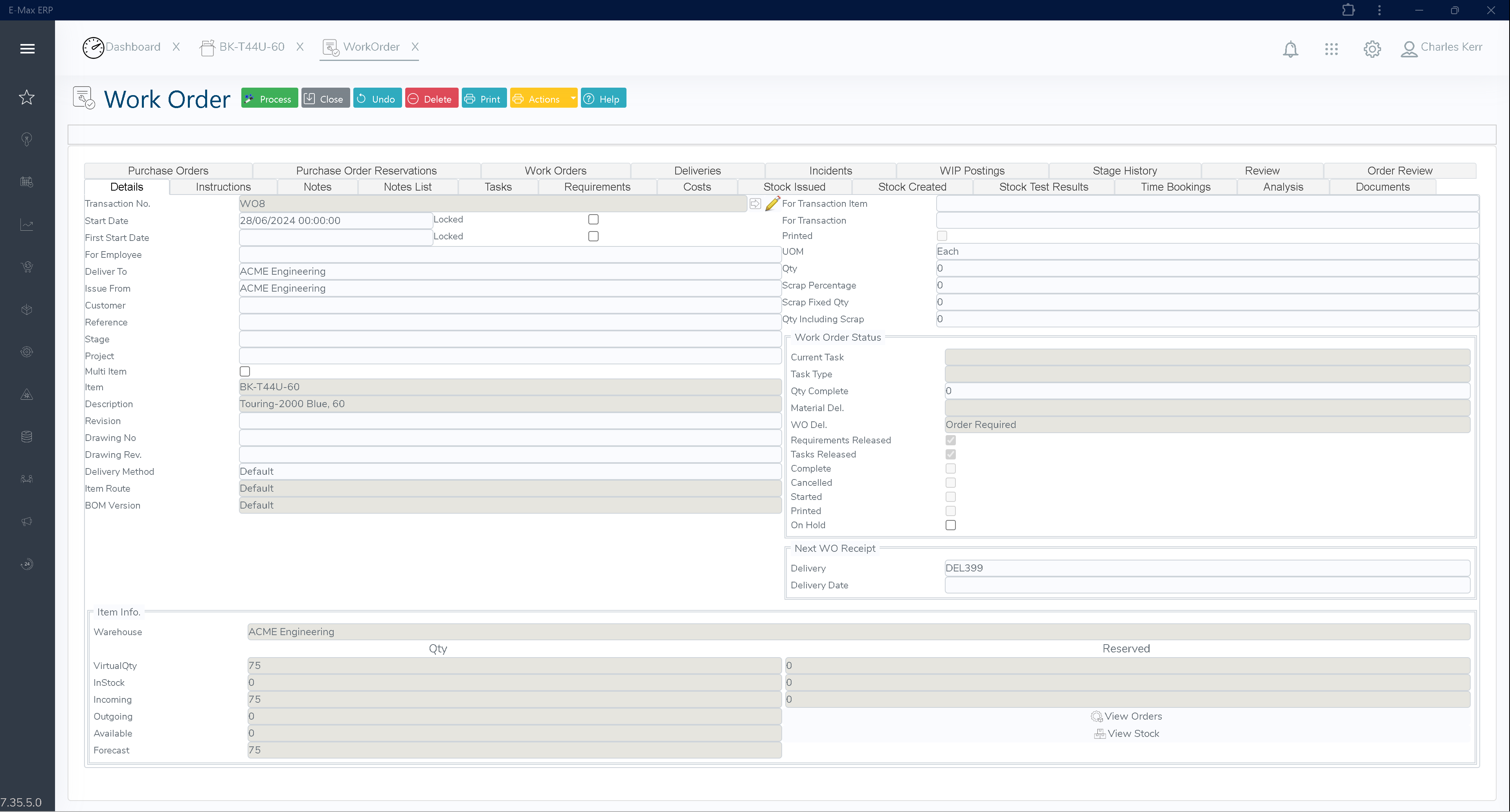

Generate works orders in a single click with E-Max ERP and keep your production moving. Guide your production team, coordinate your resources and ensure every job is manufactured to a quality standard and schedule. E-Max ERP supports multi-item works orders, allowing for nesting and by-products being returned to stock.End-to-End Traceability

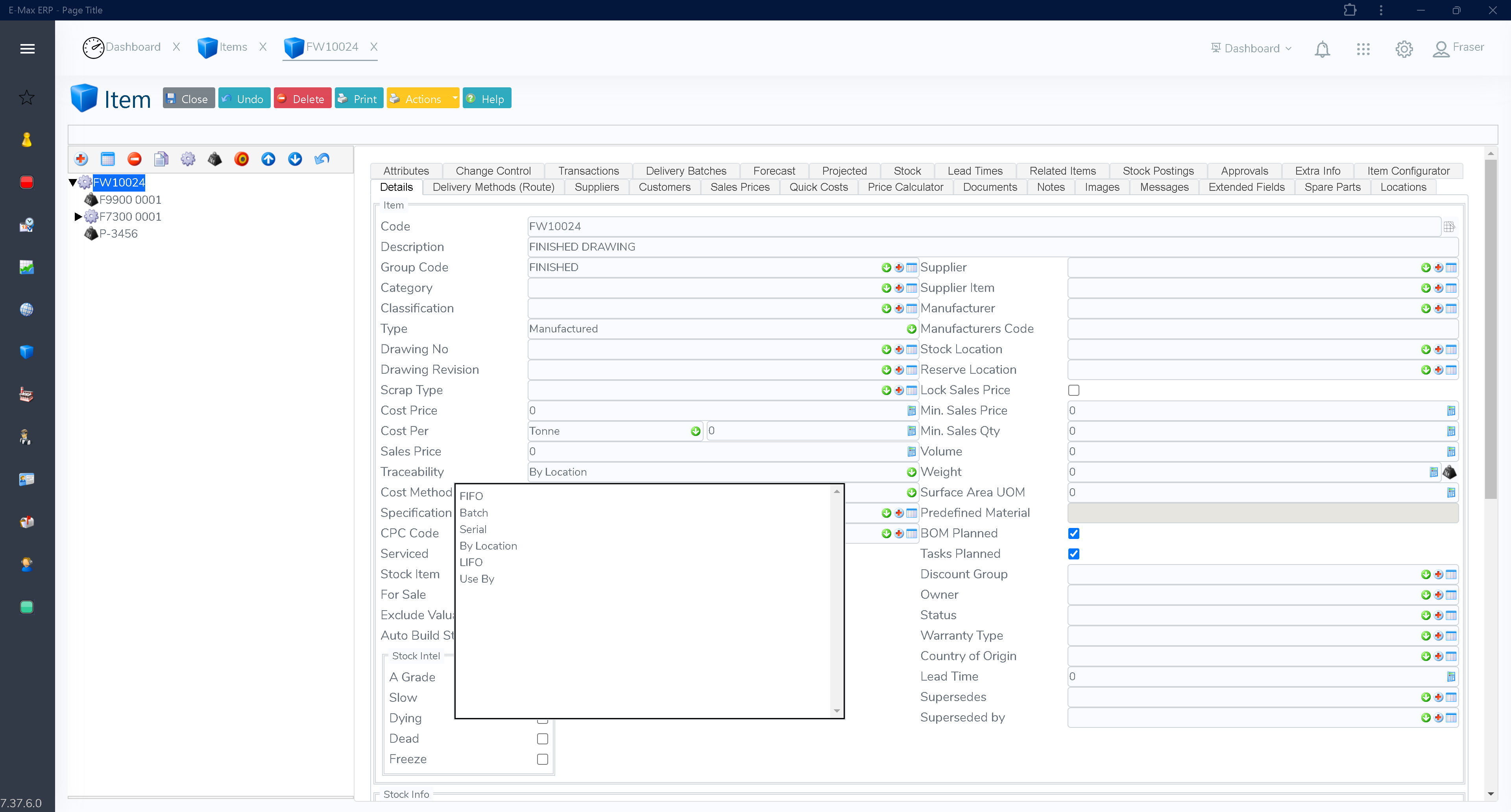

E-Max ERP tracks materials in real time across your operations, from raw material through to finished product. Track by batch, serial or lot numbers, or by date, including First In First Out (FIFO), Last In First Out (LIFO), and Use By. Production history is recorded, including machines used, settings and operators.Autobuild Stock

Simplify packing, packaging and distribution by automatically issuing a BOM for bundled items and remove these from stock.Used and Trusted by Plastics Manufacturers

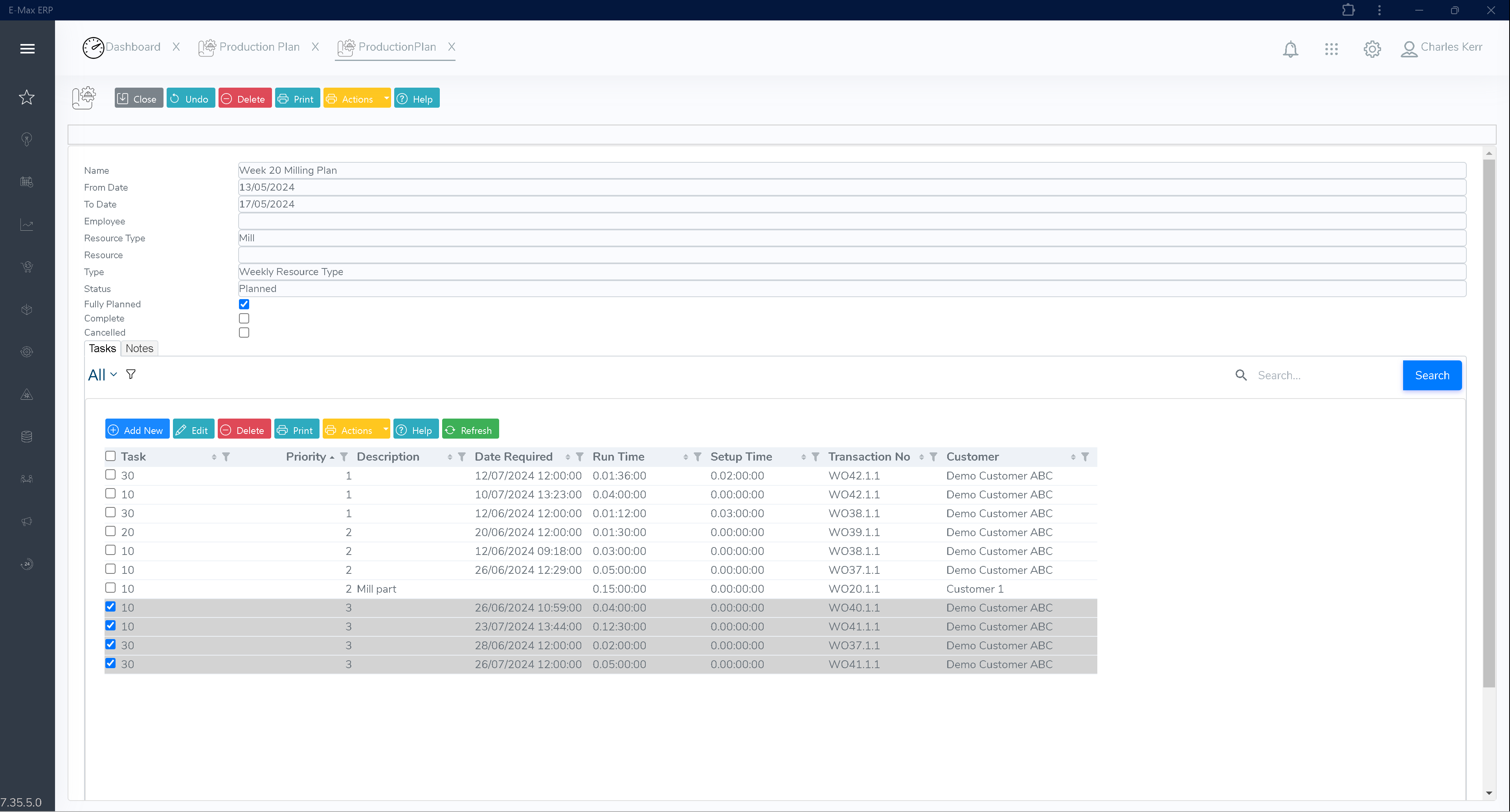

Manage Your Resources Effectively

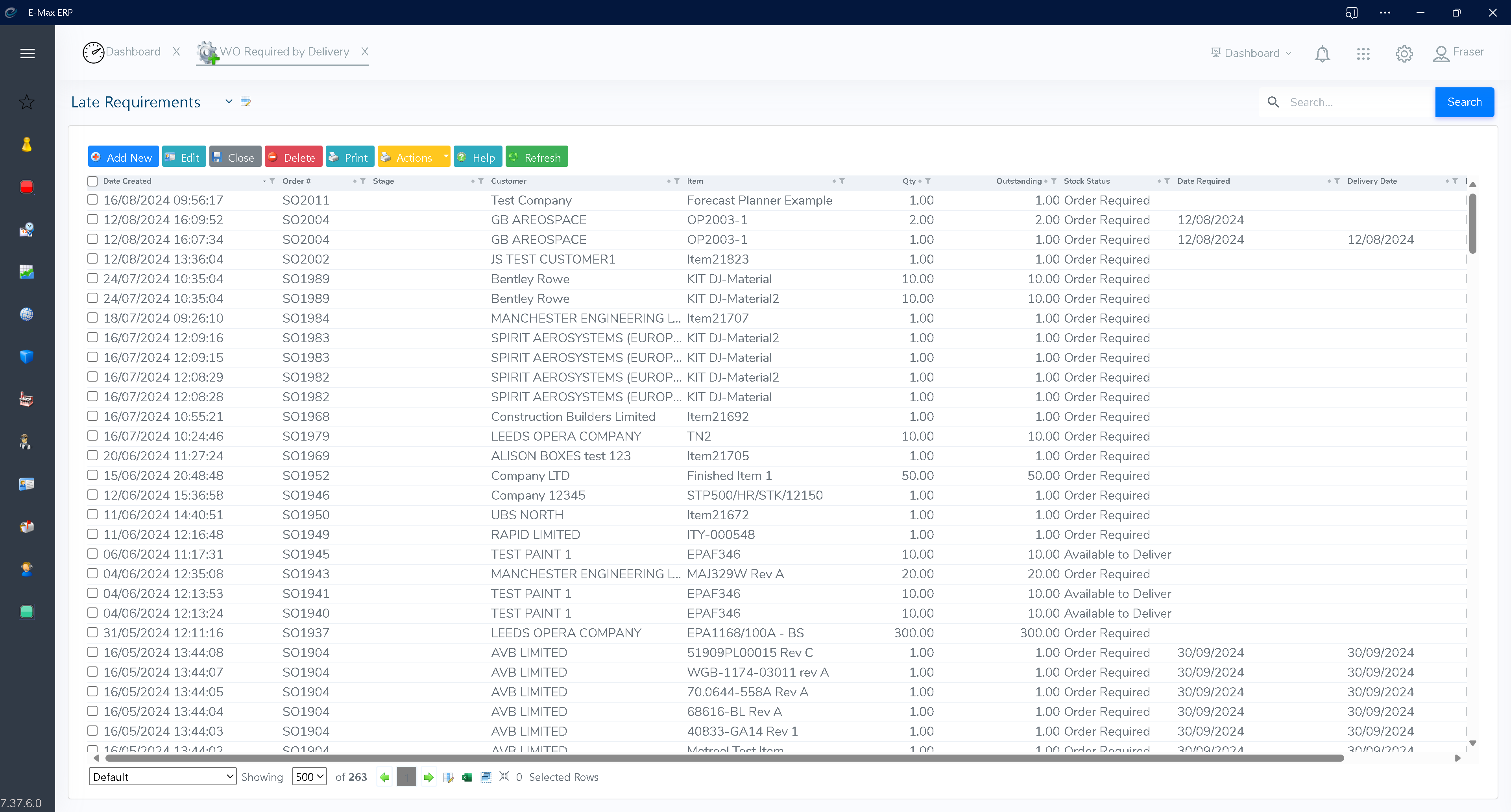

Take your MRP to the next level with E-Max ERP as you plan, monitor and organise your resources to meet customer deadlines. E-Max ERP allows you to schedule activities, taking into account availability of labour, including specific skill levels, machinery, tools, and workstations to create optimal production plans. In addition to daily, weekly, and monthly planning, our MRP functionality can be used for long term planning and forecasting.Identify Your Available Capacity

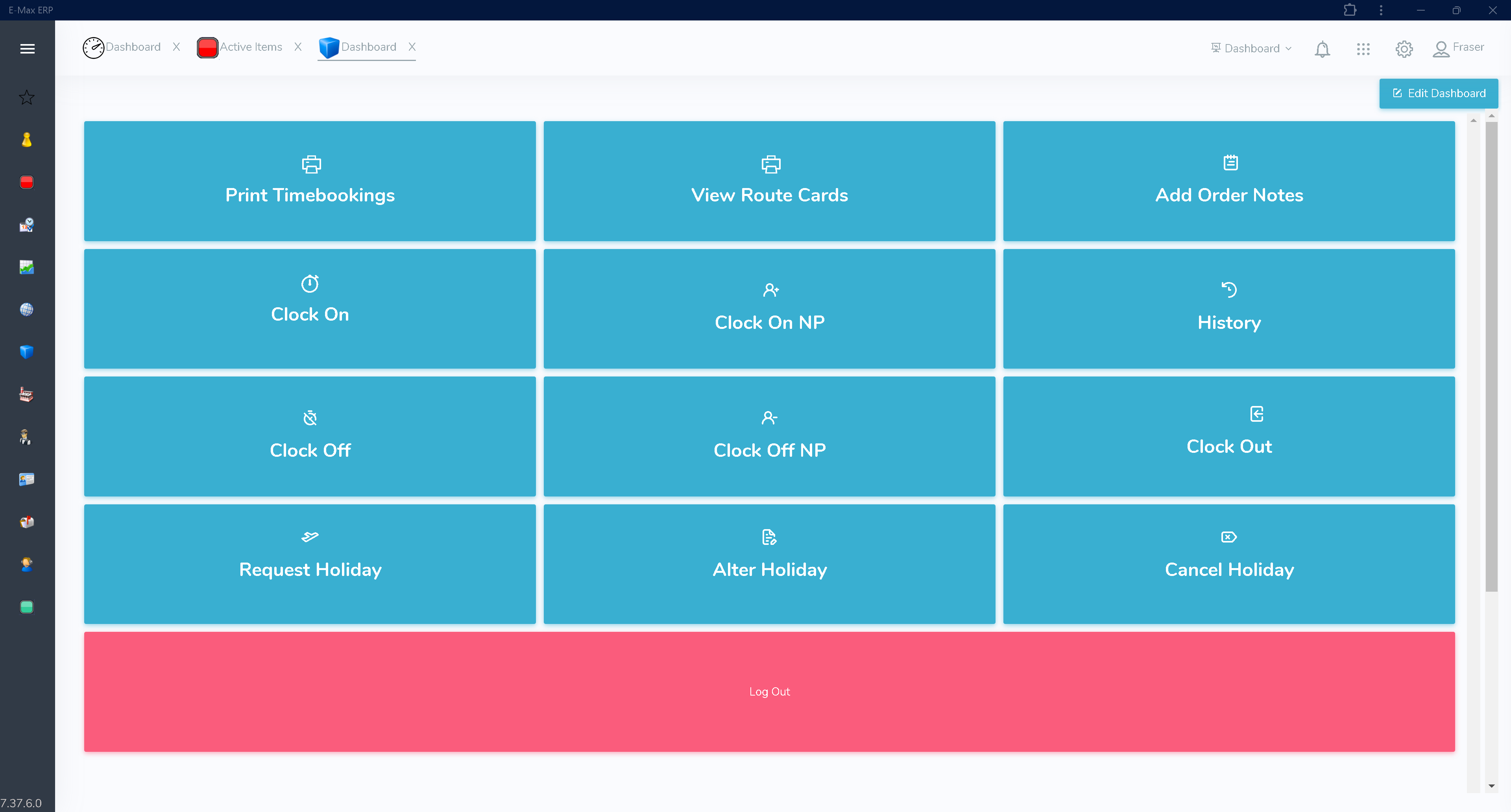

Maximise your machine usage by understanding when your machines are running operations or not, allowing you to take on additional work. E-Max calculates the most efficient use of materials and resources to maximise your capacity.Shop Floor Data Collection

Record time bookings for accurate job costing from the shop floor. Our SFDC functionality allows operators to view drawings, instructions and route cards with barcoded tasks or operations.Key Analytics and Reporting for Plastics Manufacturing

See the KPIs that matter to you on E-Max's customisable dashboards. Track work orders, stock levels, quality, production targets, waste and costs and understand exactly how your plastics manufacturing business is performing.Multiple Unit of Measure (UOM) & Conversions

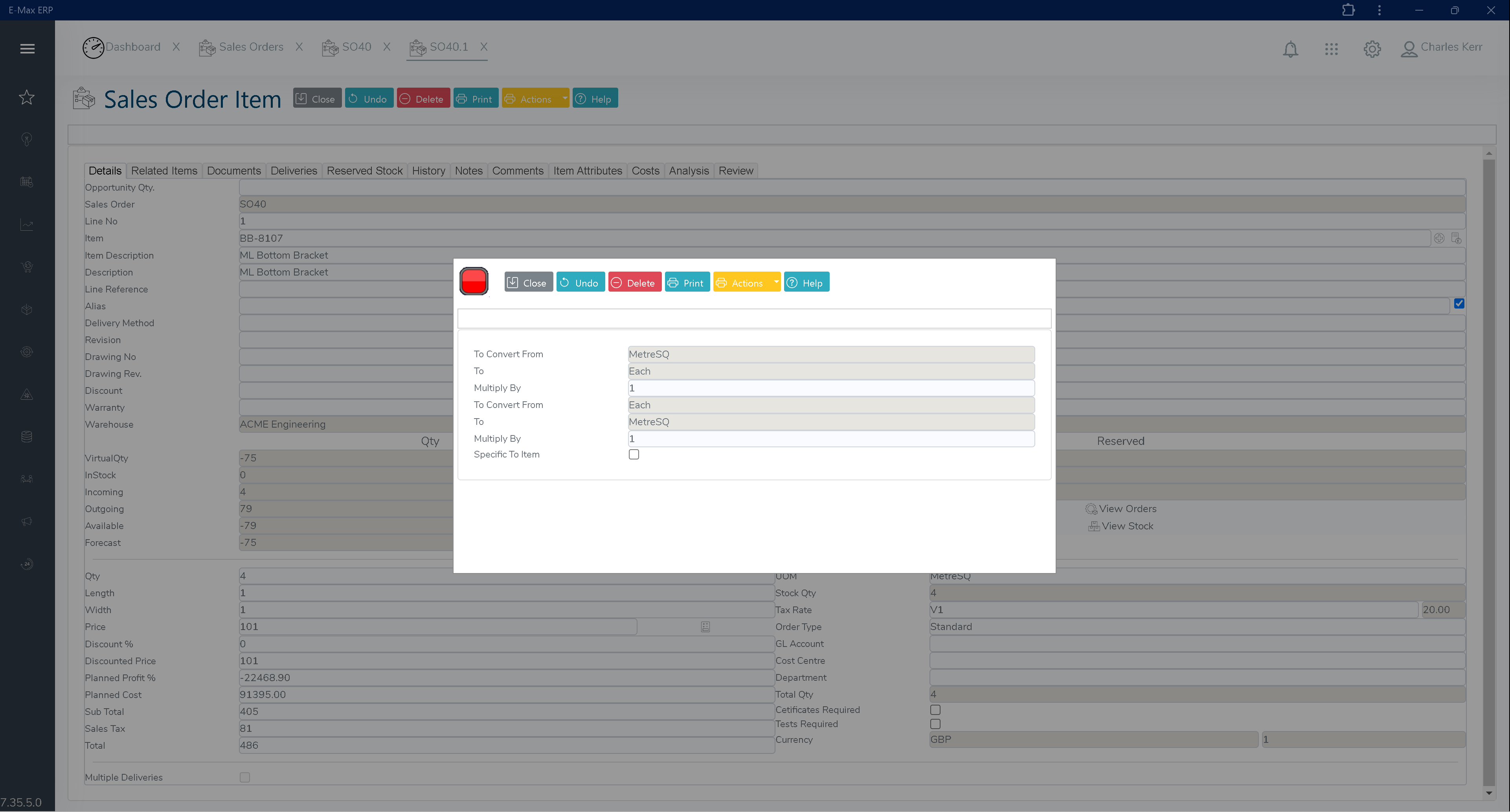

E-Max ERP gives you the ability to measure materials precisely, based on your preferences. Stay in control of various units of measurement for your inventory. Establish conversion ratios directly within the system, ensuring seamless management of sales, purchases, and stock transactions. The system will seamlessly manage all conversions on your behalf.E-Max ERP Software

offers all of this and more:

.png)

.png)

.png)

.png)