Quality Management

Customers’ ever-increasing need for quality products means that it is vital your company has a robust quality control system in place. E-Max ERP contains a comprehensive suite of quality management software to ensure that your business can maintain high quality products and minimise wastage.

.png)

Embrace a Continuous Improvement Culture

E-Max ERP’s sophisticated quality control system allows all processes to be tracked and any areas needing improvement to be identified, enabling your company to produce consistently high-quality products.Supplier Quality Management

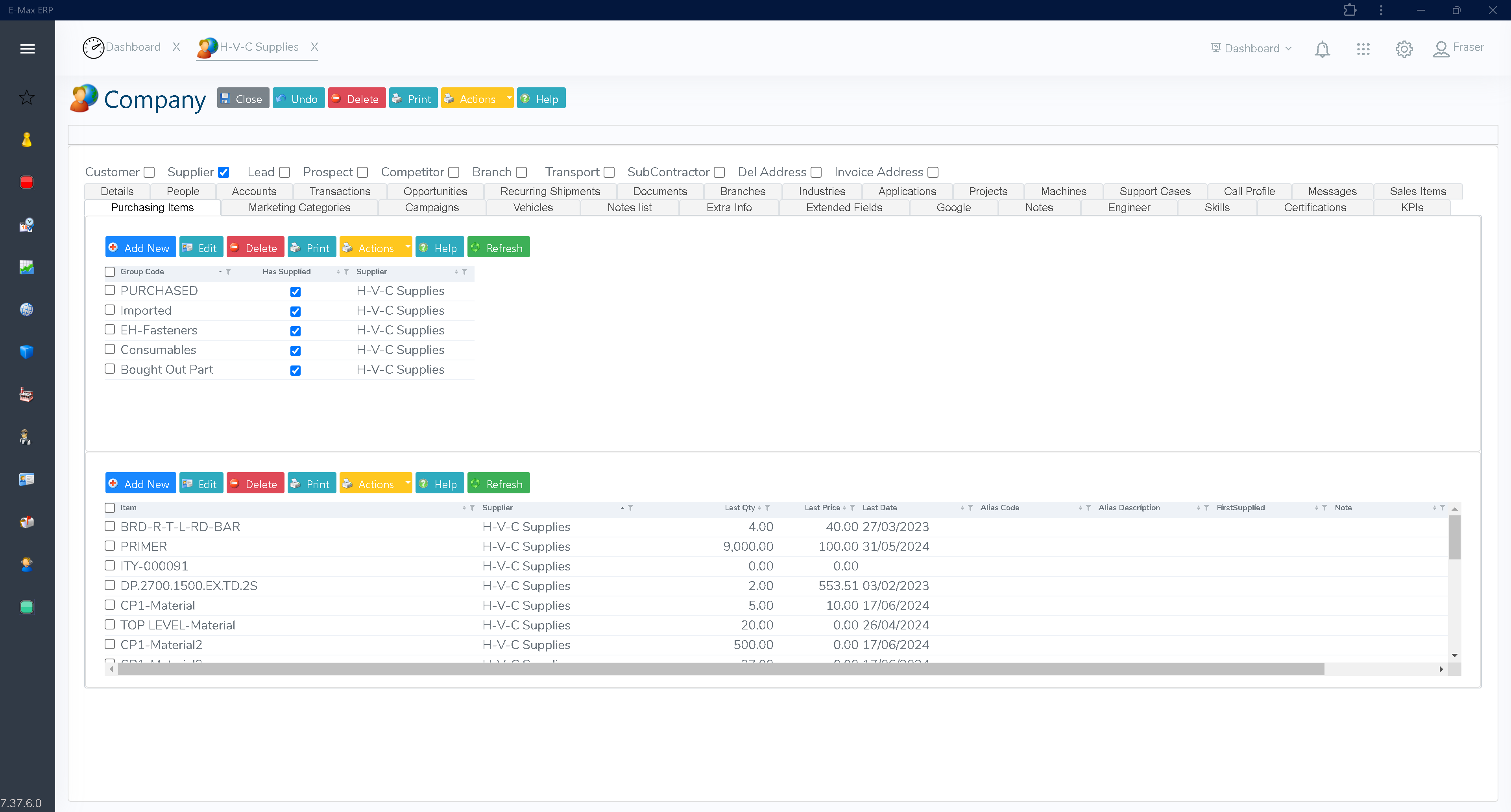

Monitor and assess the quality of materials and components received from suppliers. Useful for supplier evaluations, performance tracking, and the management of supplier-related documents. E-Max ERP also includes supplier approval to ensure your suppliers meet required standards.Develop Comprehensive Inspection & Testing Procedures

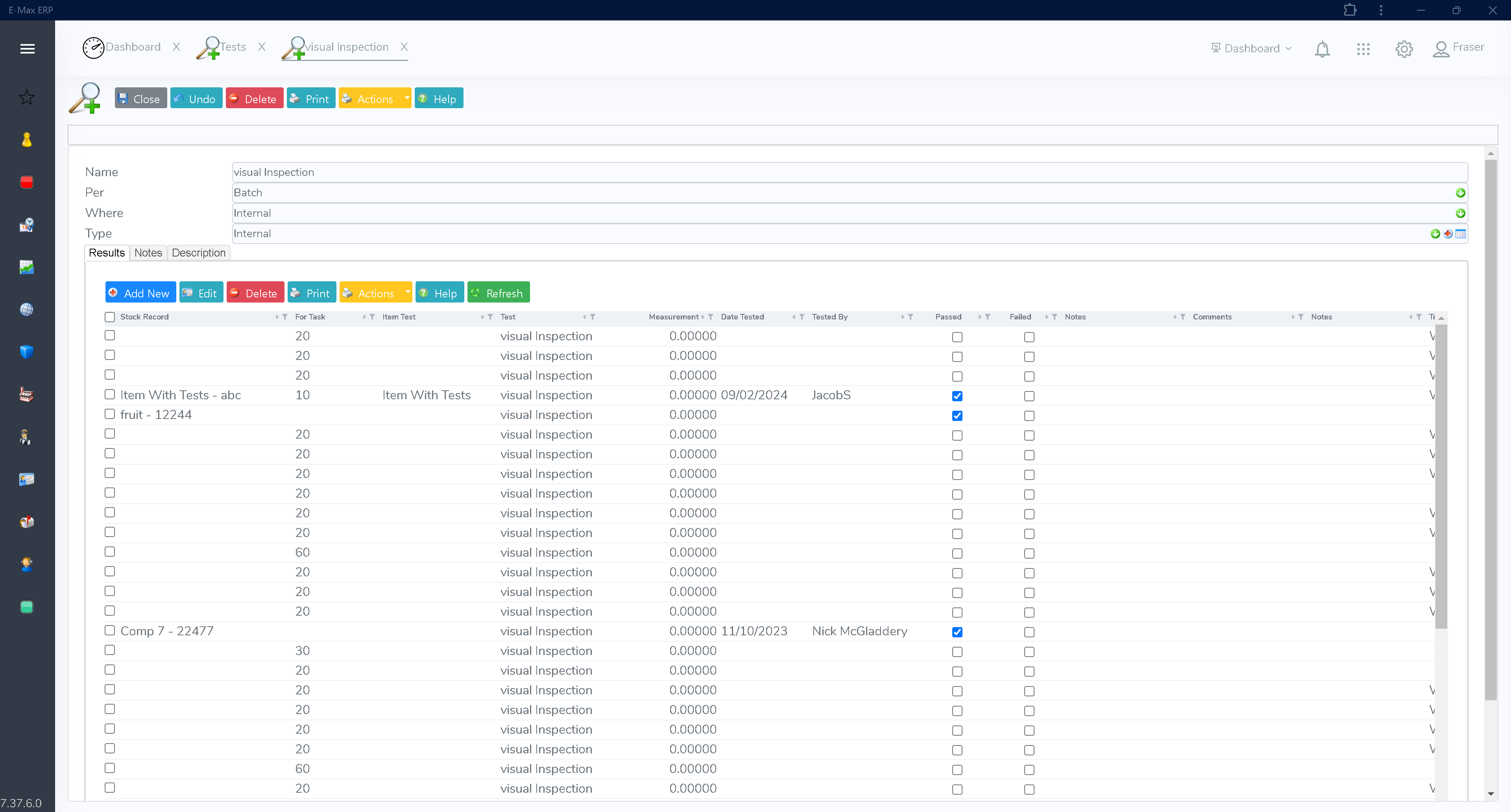

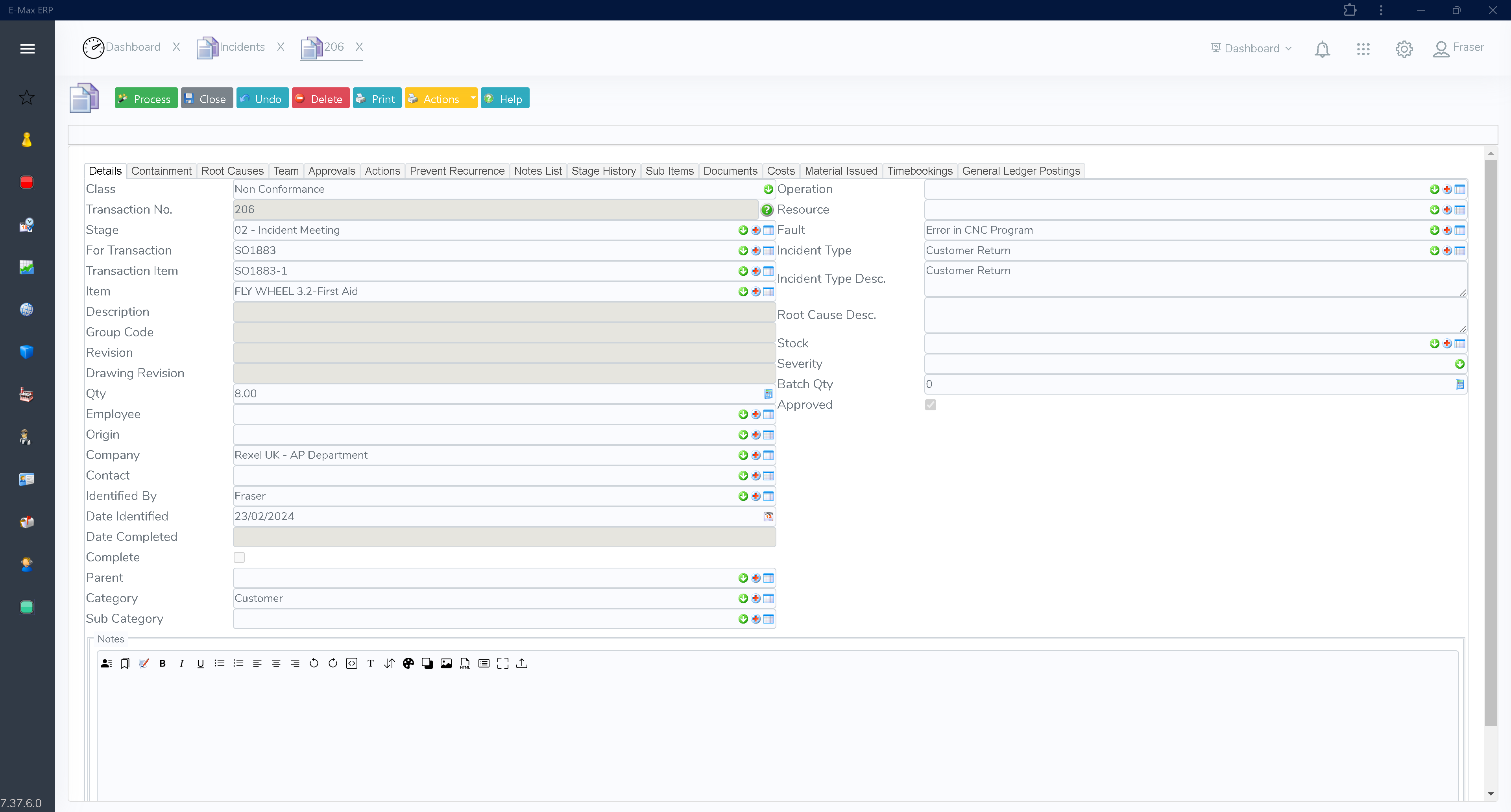

With E-Max ERP, you can create and execute inspection and testing plans to ensure that quality checks are conducted consistently and according to established criteria. Identify, record and manage incidents and initiate corrective actions to address issues and prevent reoccurrence. E-Max ERP allows you to add custom fields to suit your business, and define your own categories of non-conformance, breakdowns, accidents, complaints or customer returns, or production incidents, such as: supplier, manufacturer, delivery, tools, etc. E-Max’s flexibility enables users to record every non-conformance or error. The system will also generate tasks for preventative or corrective measures.Document Register/Control

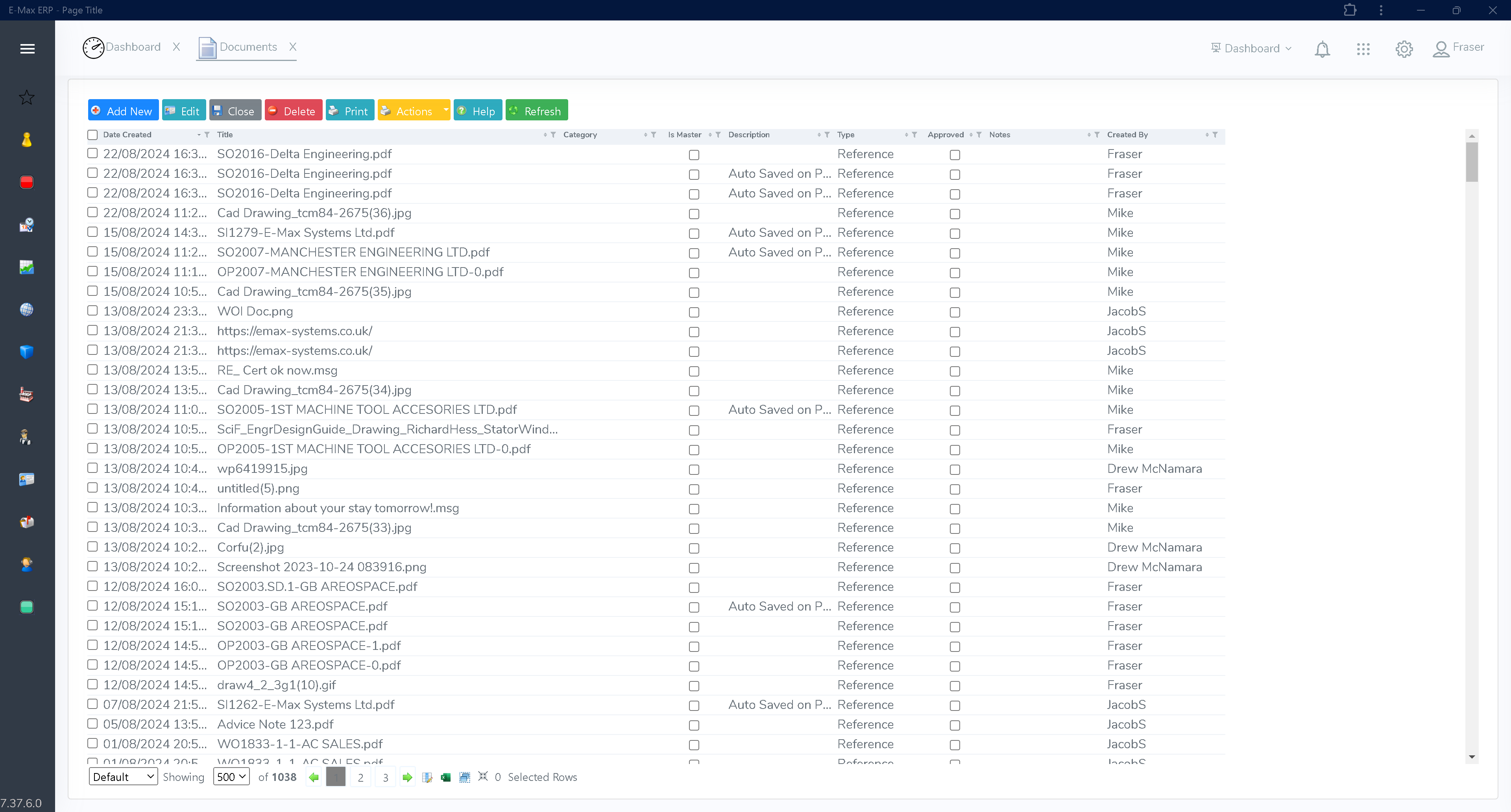

Centralise and manage all quality-related documents, including standard operating procedures (SOPs), drawings, test results, certificates of conformity, instructions, images, inspection reports and specifications. Ensures your team has access to the latest, approved versions of documents. E-Max ERP will also create and administer prepopulated quality documents. All documents relating to each job are collated into a convenient job pack which can be easily accessed from anywhere within the software.Full Traceability

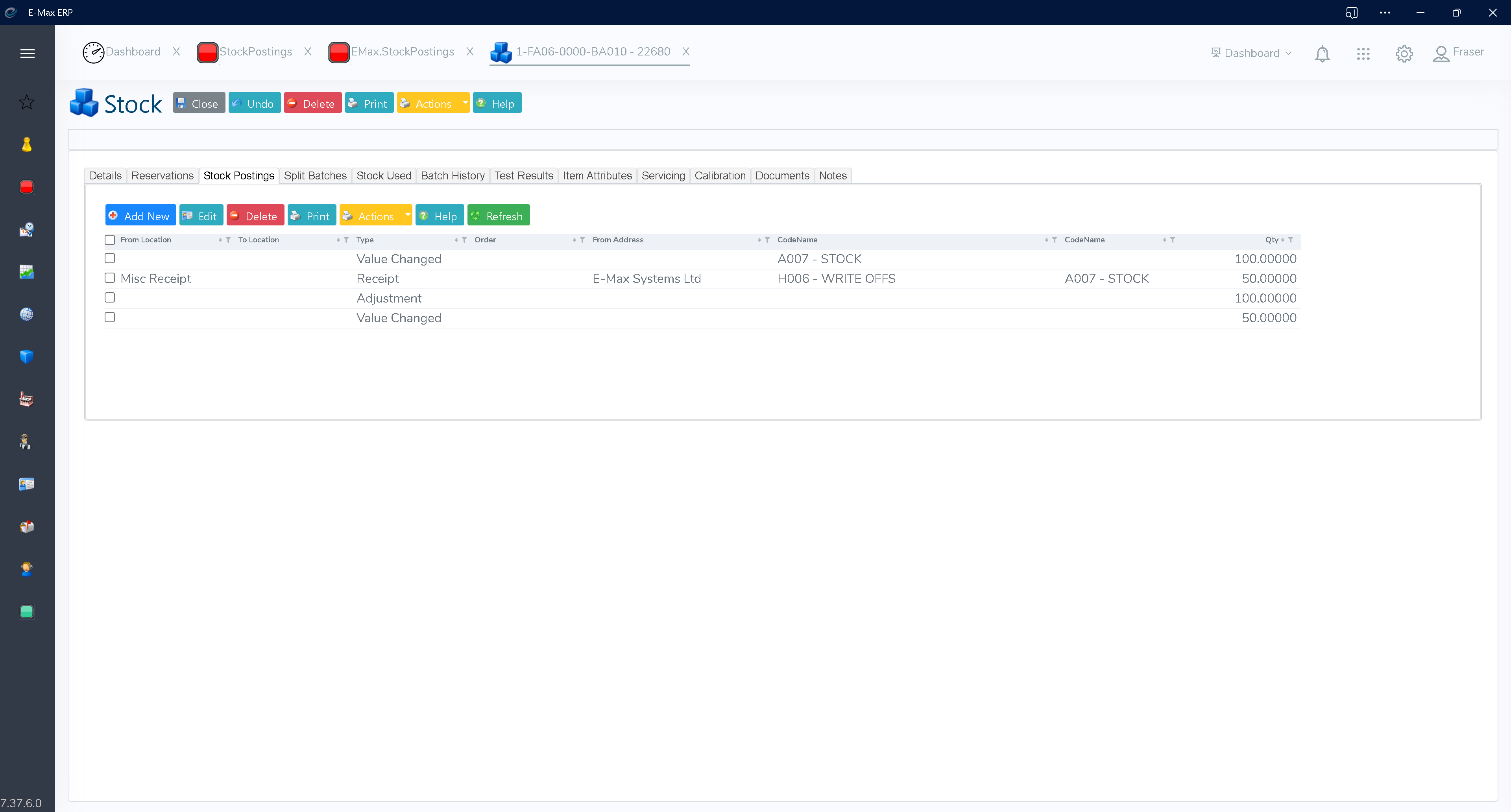

Easily track and manage raw materials, components, and finished products from supplier, through the production process, and onto the end customer. E-Max ERP’s traceability functionality automatically records and archives all data, including materials in and finished items, producing appropriate documentation, such as certificates of conformance, non-conformance or incident reports, and test certificates.Root Cause Analysis

Identify the underlying issues that contribute to production problems and quality issues, so that you can implement effective corrective actions. E-Max ERP offers the tools to conduct thorough root cause analysis in a systematic manner, using various methodologies including 8D.Manage Accreditations and Stay Compliant

For companies operating in a regulated industry, E-Max ERP makes it easy to create and follow processes to ensure your team is compliant with current regulations. E-Max ERP can also be used to achieve and retain industry accreditations such as ISO 9001 and offers a full audit trail to demonstrate compliance with the required standards. The system will also generate reports and documentation required for regulatory purposes.Get Visibility of Quality Metrics and KPIs

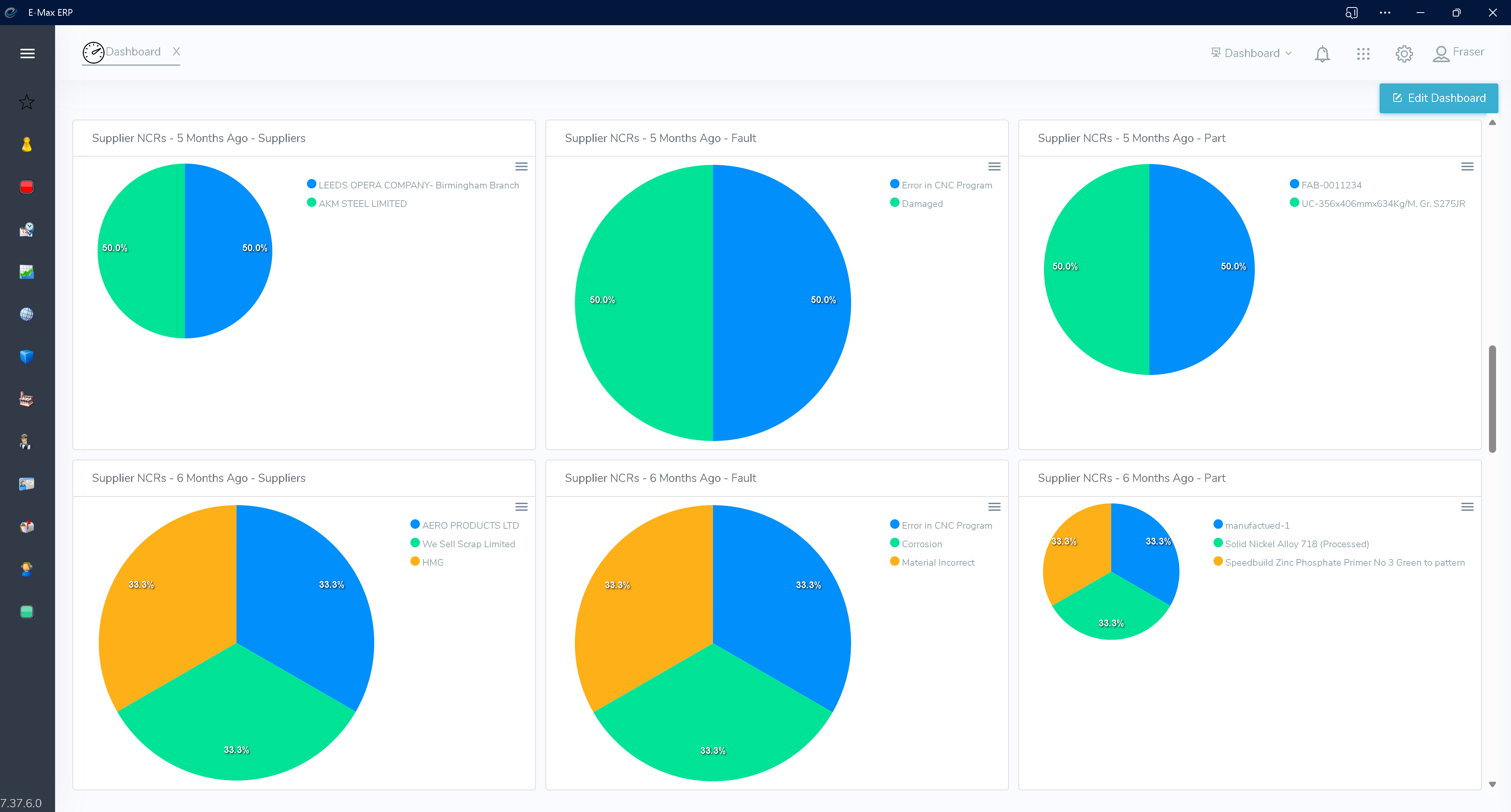

Get insights into the effectiveness of your quality control processes and drive continuous improvement with E-Max ERP’s quality-related metrics and KPIs. Gather real time data, track, and report on the key performance indicators for your business with E-Max’s modern dashboards.Full Audit Trail

E-Max ERP traces and verifies your entire manufacturing process, from raw materials to the finished product. All information is stored and can be accessed or exported at any time to identify issues or provide evidence of adherence to SOPs.Testing

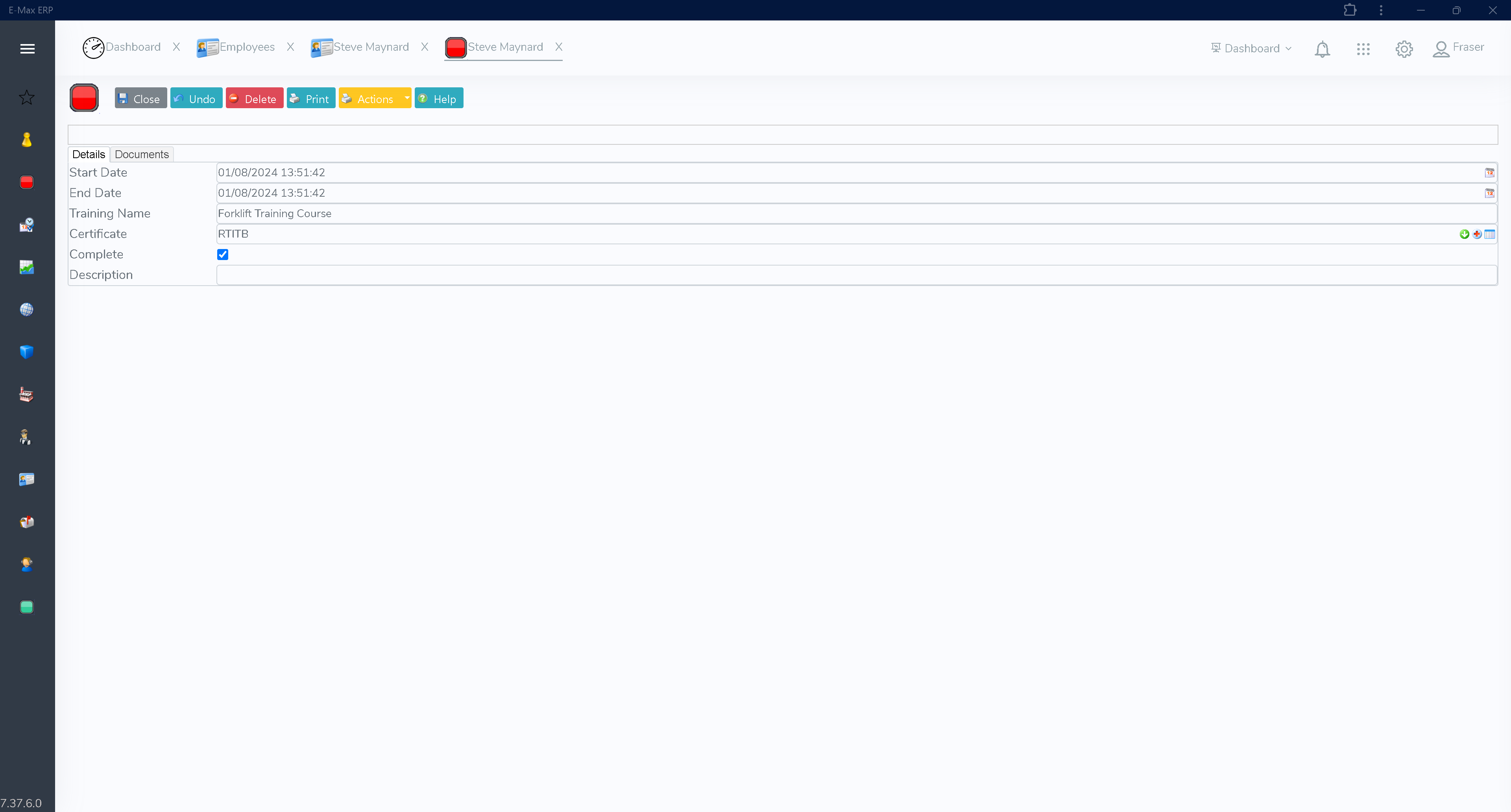

Define any tests, i.e., dimensions, chemical properties analysis, hardness, etc, you want to perform against any batch, serial, or lot, and record the test results for each against the stock record. Testing can also be specified to first off or in-process, in-house or external. Test certificates are then generated from the test results and can be attached to any batch, serial, or lot.Integrated Calibration System

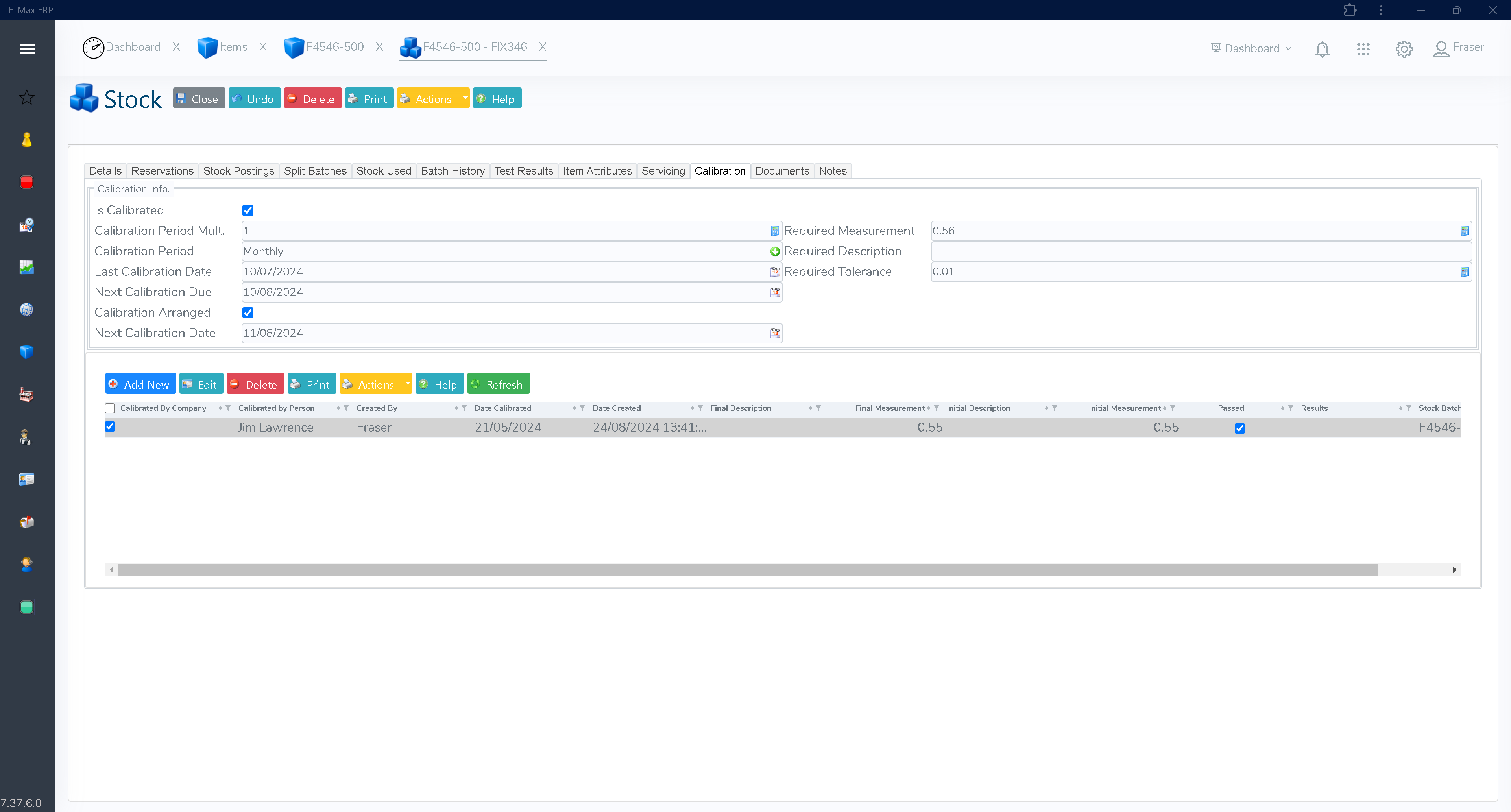

Maintain calibration records (and any relevant other information) for all your machines or tools in E-Max ERP. Store calibration tolerances, set calibration periods for any specific time period, ie daily, weekly, quarterly, etc, and record the details of every calibration performed, by whom and the results, to build a full calibration history for each machine or tool.Calculate the Cost of Quality

Track the cost of quality and make informed decisions based on real time data. With E-Max ERP reporting, it is easy to identify how much quality is costing you, ie in terms of returns, machine breakdowns, sub-standard products, etc.Time to reduce your quality issues?

We can help

E-Max ERP Software

With E-Max ERP you can easily manage

.png)

.png)

.png)

.png)