Shop Floor Data Collection

SFDC is an additional module to the core E-Max ERP software and is designed to complement and enhance the data gathered in production. Shop Floor Data Collection enables a deep dive approach into time and attendance and is particularly useful for identifying and reducing downtime of employees and machines.

Take Control of your Shop Floor

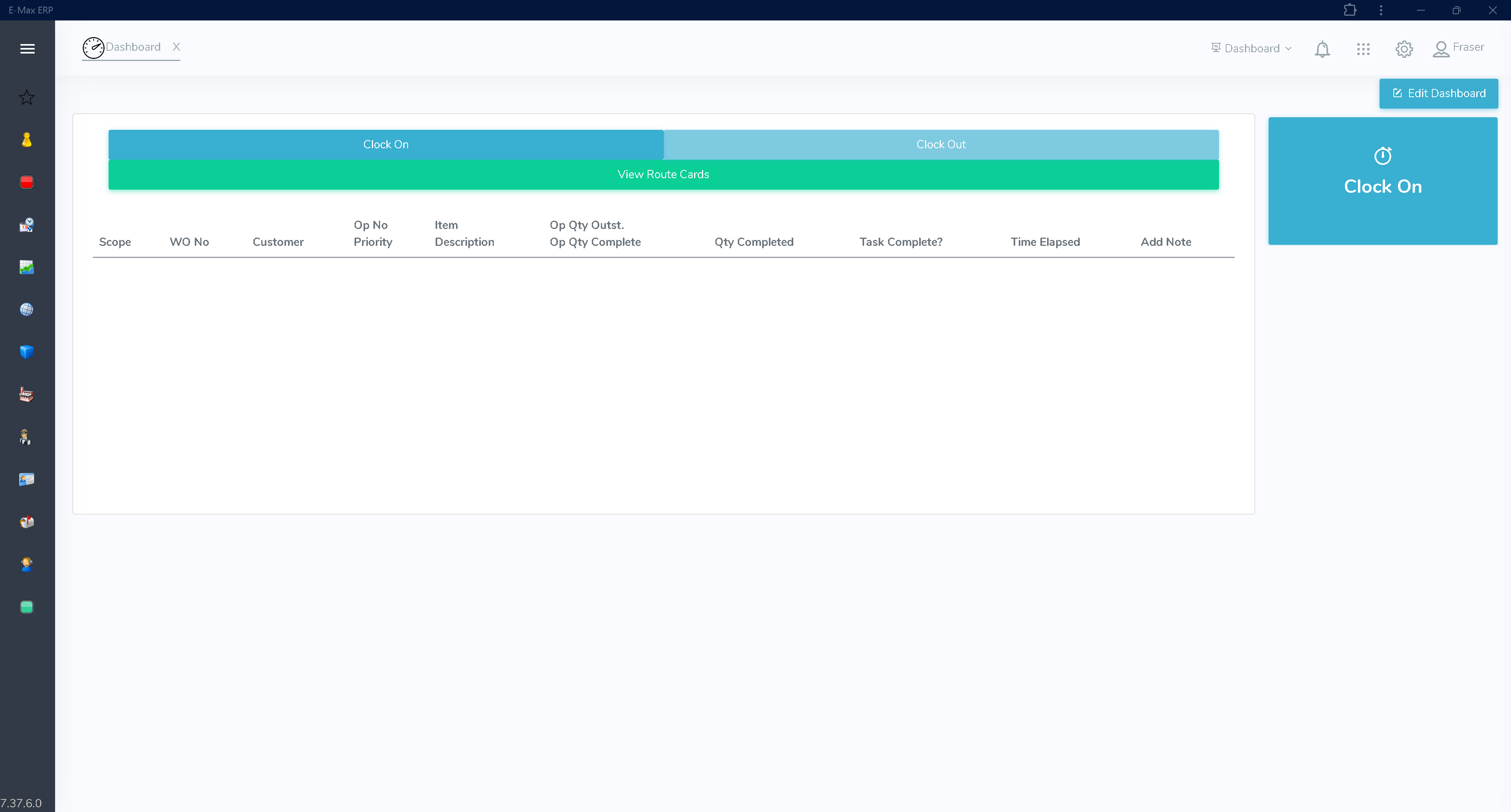

E-Max ERP’s SFDC provides manufacturers with a cutting edge but inexpensive means of collecting key data directly from the shop floor. It’s a simple yet effective way of capturing real time, accurate data on labour, resources, and job costs, and can save time and manufacturing costs, reduce errors and increase productivity on the shop floor.Track and Manage Time & Attendance

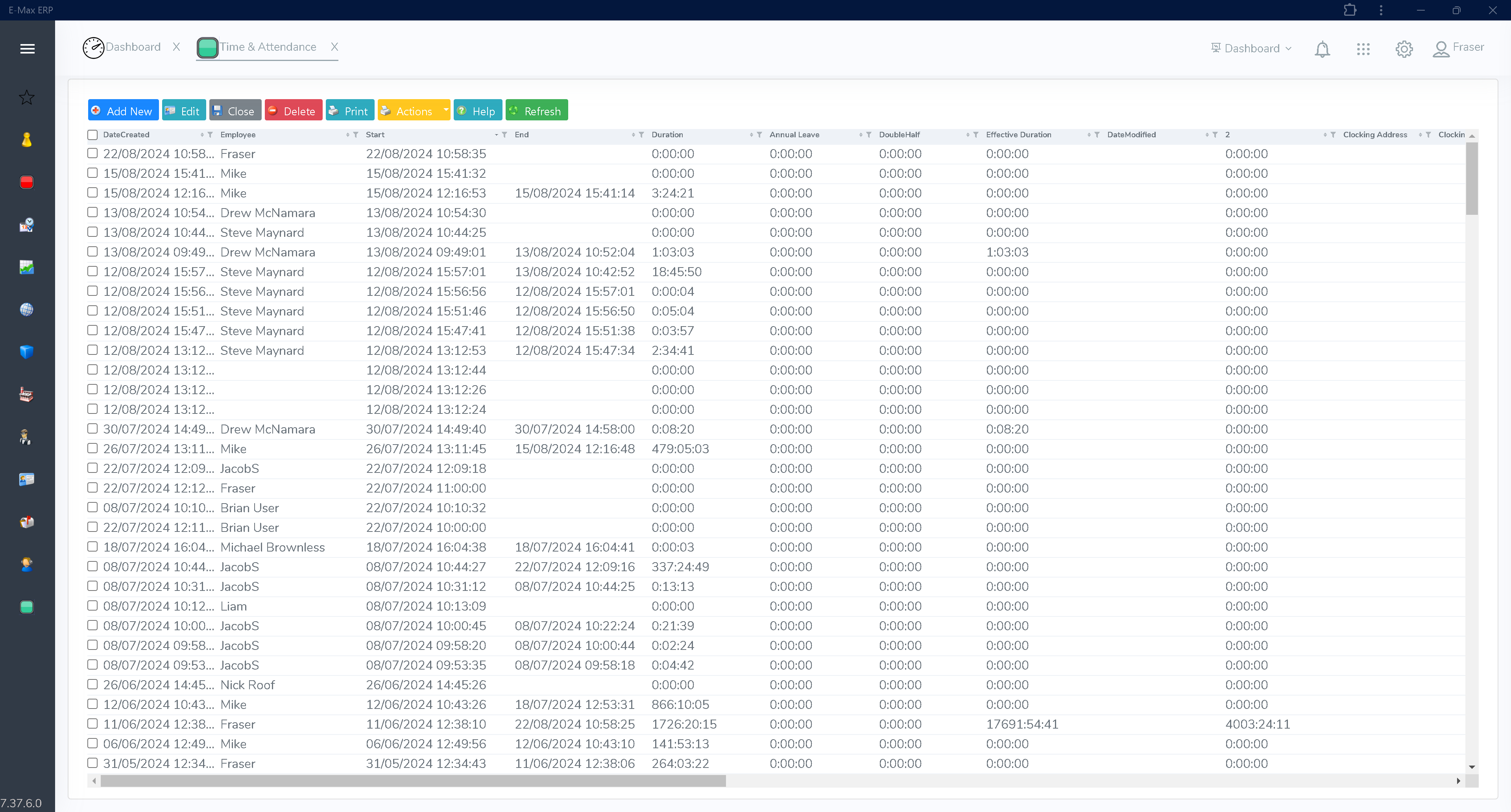

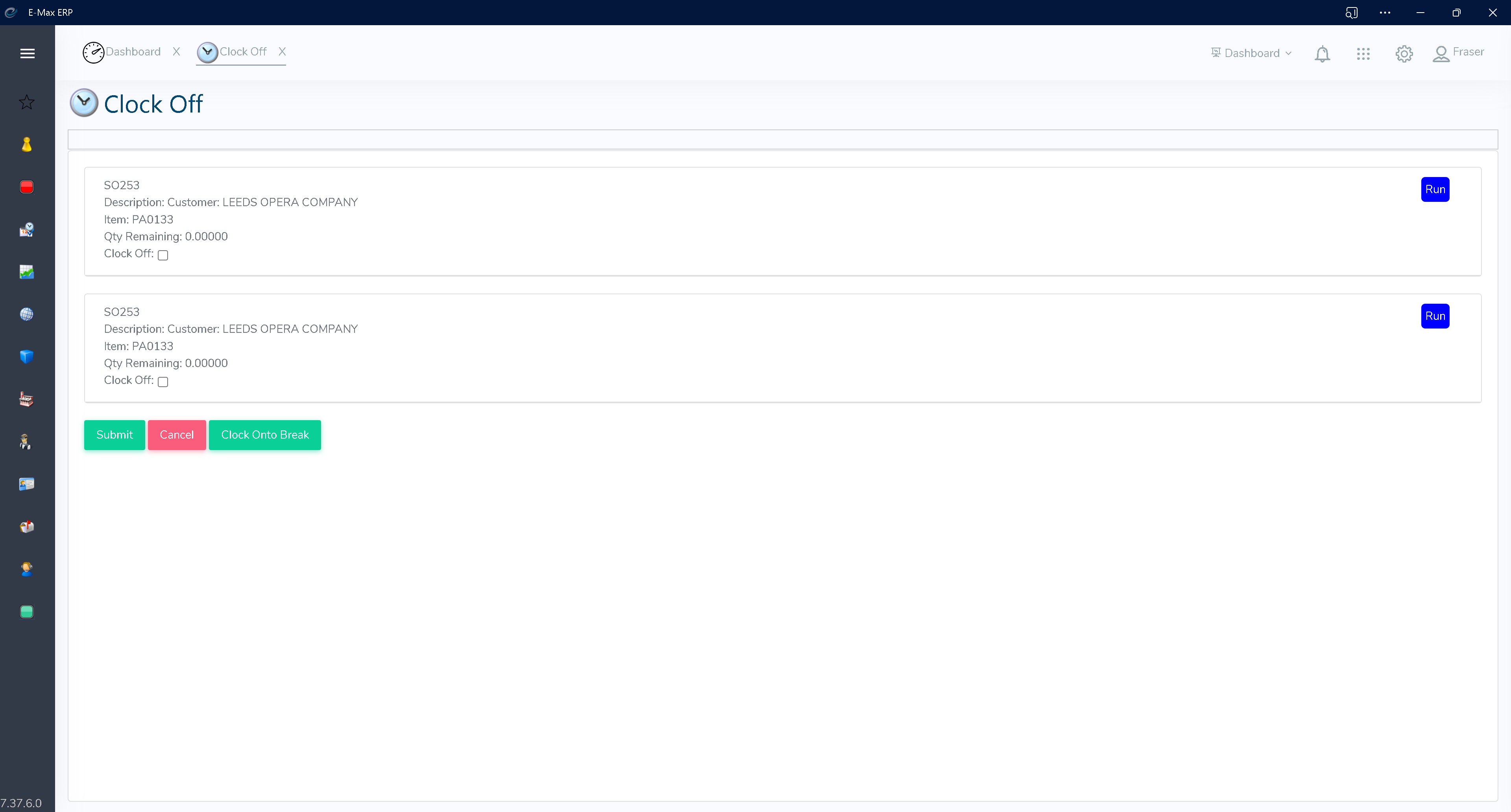

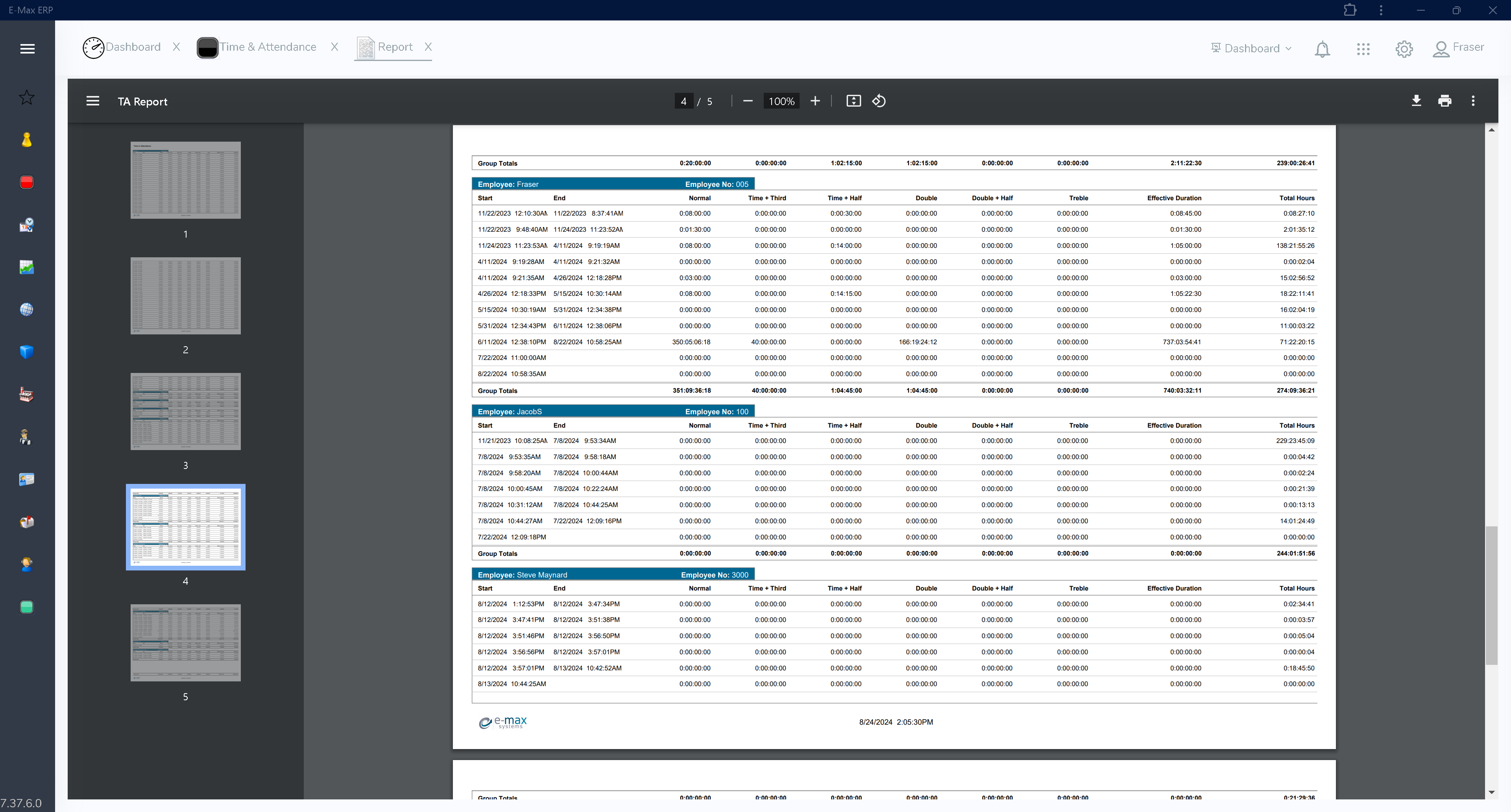

Accurately record working hours, attendance and labour activities of your shop floor personnel. From clock in and out (both business and individual job options); shift tracking and absence management, the data recorded in E-Max’s SFDC can be fed into payroll systems and ends manual, time-intensive recording and inputting of timesheets.Record Time Bookings for Accurate Job Costing

Know exactly what a job costs you in terms of resources and labour with E-Max’s SFDC. Record time spent even before manufacturing commences, ie capture design time. This information is attached to the sales order and attributes these costs to the job.Get Visibility Across the Shop Floor

The system gives a full overview of employees who are clocked in and highlights any non-adherences to assigned shifts or hours, including information on planned and unplanned absences. Dashboards can be set up to display number of absences, with full list views of all who are clocked in just a click away.Machine Dedicated Mode

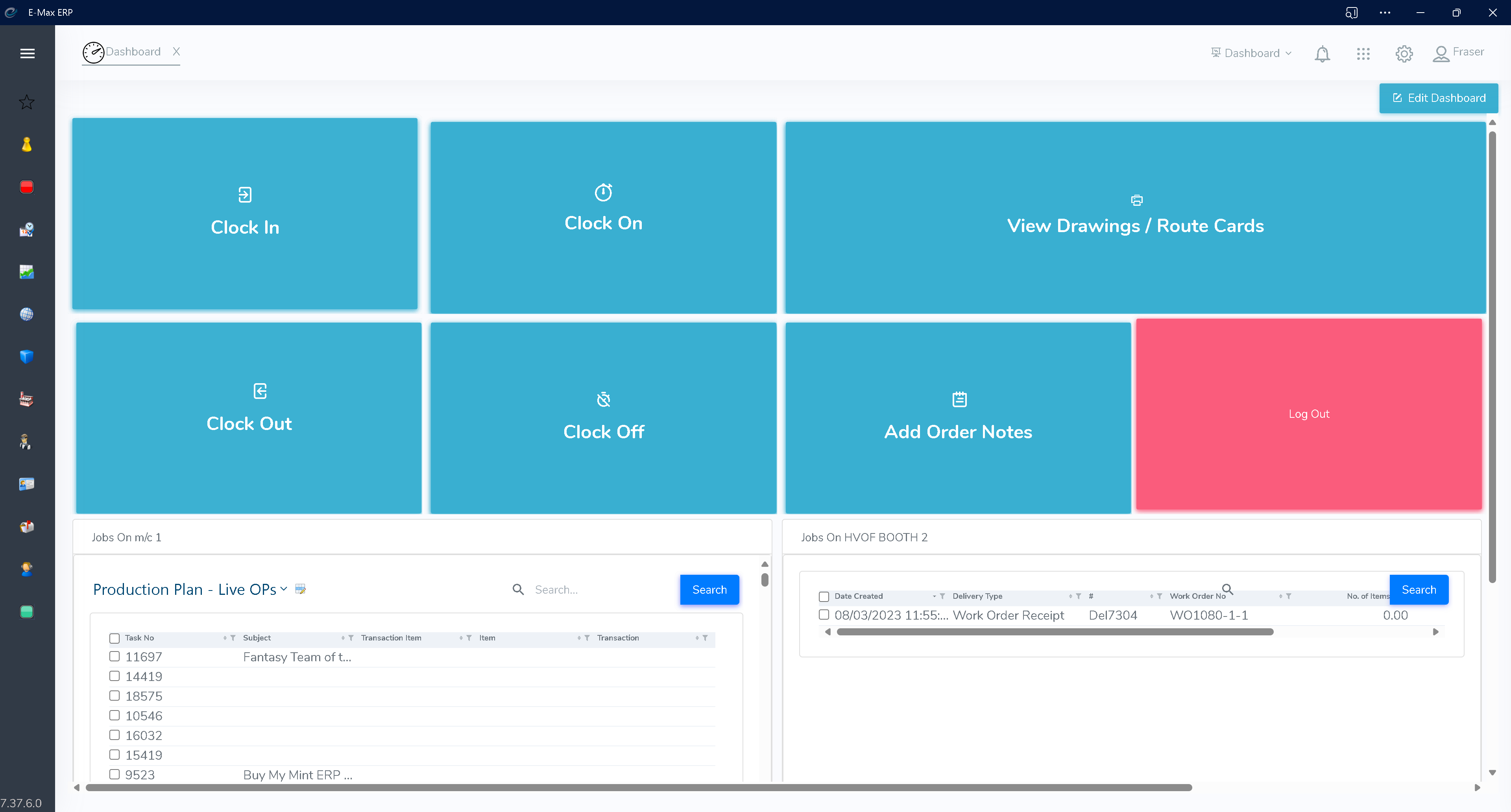

In addition to our standard SFDC which can be used across the shop floor, E-Max also offers the option of using machine dedicated terminals to capture the data specifically from each machine, providing intelligence on machine performance , OEE, downtime periods, utilisation rates and maintenance activity.View Drawings & Instructions

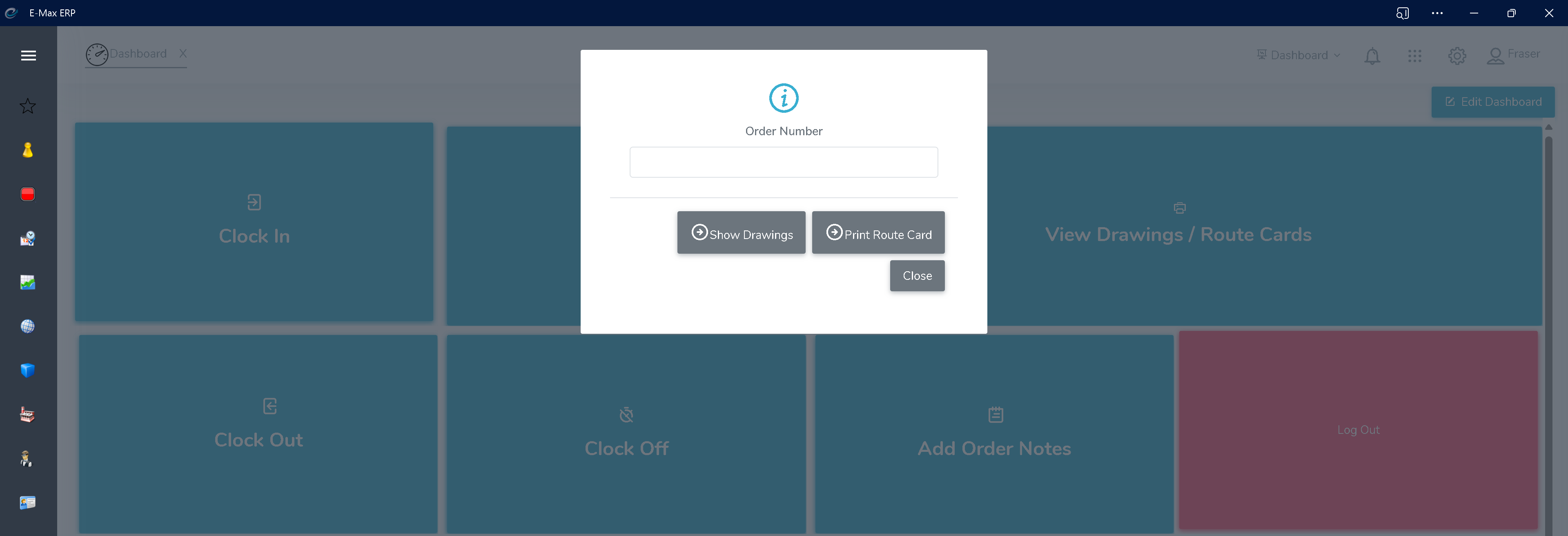

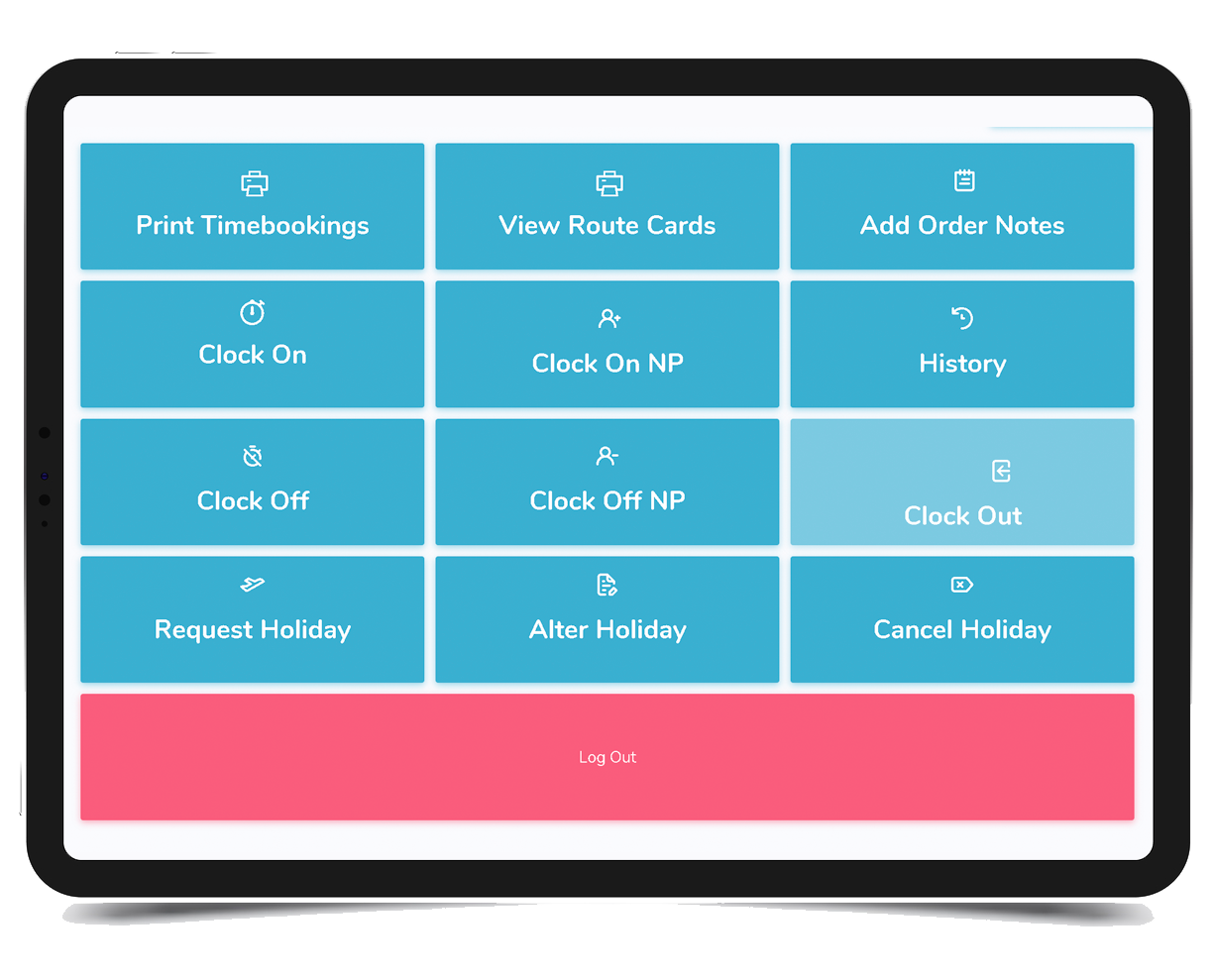

Any drawings or instructions attached to a job are pulled into the SFDC directly with the work order. Provided the terminal, ie tablet or PC, has the relevant document viewer installed, any shop floor operative can access these documents, list of instructions, etc, and easily read these on the terminal, removing the need for paperwork on the shop floor. Route cards can also be accessed this way and tasks or operations clocked on to from the terminal. If there is a requirement to print or email information, ie a list of time bookings, this can be done from within the SFDC, making it an ideal tool for a field service environment.Multiple Customisation Options

E-Max ERP’s SFDC offers companies a huge amount of customisation, allowing each company to make SFDC work appropriately for their business. With a range of settings available, companies can quickly and easily select as many or as few options on each individual terminal, keeping it simple where necessary (ie clock on/clock off) or bringing in a wider range of options for comprehensive data collection. Capture the resource being used, quantity complete, scrap quantities, scrap reasons, rework information, prevent operators from clocking out if clocked on and other valuable data.Reduce Errors

E-Max’s SFDC system settings can prevent standard user errors from occurring, saving your admin team time making manual corrections. Use settings to prevent operators from clocking out whilst still clocked on jobs, etc, or design simple terminals with minimal options, ie clock on/off. Barcodes can also be used to record activities accurately.Log onto Multiple Jobs at the Same Time

When setting up or running multiple machines, it is not always practical or time efficient to clock on and off jobs multiple times. E-Max’s SFDC offers the opportunity for operators to clock on to multiple job/operations simultaneously.Record Non-Productive Time

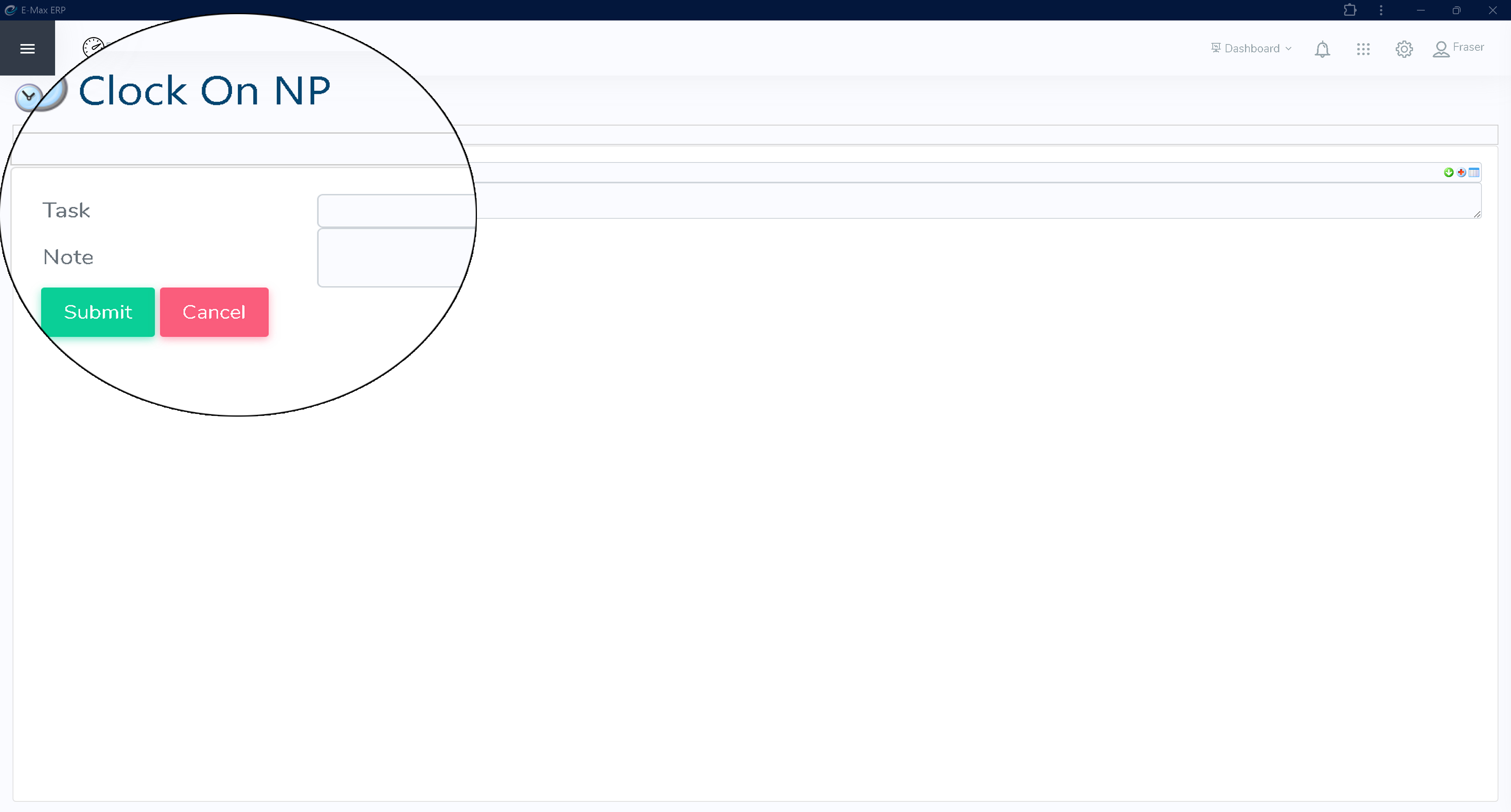

During any downtime or when tasks not related to production activity, ie machine clean, general clean, painting, etc, need performed, these can be classified as non-productive tasks. These tasks are user defined and allow you to calculate and cost time spent on these activities.Communicate Issues From the Shop Floor

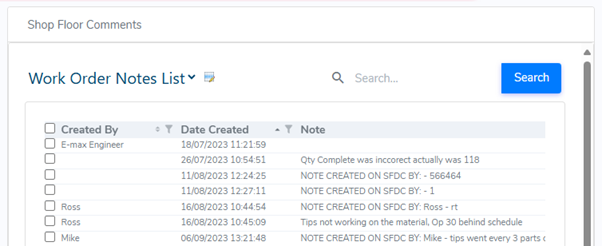

Notes can be recorded on the SFDC and highlighted to appropriate people, such as Quality Managers. If an operator detects an issue with a machine, faults with material, problem with run time, etc, this can be recorded during or at the end of an operation. Dashboard KPIs can be set up to highlight notes for quick remedial action. This information will also flow through to the work order directly. Information can also be communicated directly to the next operator via notes.Powerful Reporting Capabilities

E-Max’s SFDC offers a wide range of reports, including periodic time control, standard time bookings, number of hours per employee to jobs, non-productive, and unallocated.Want to accurately track your shop floor activity?

We can help

E-Max ERP Software

With E-Max ERP you can easily manage

.jpg)

.png)

.png)