Effective Stock Management

Track your inventory in real-time, send automated alerts when stock levels fall below a certain threshold, and use barcodes to quickly and accurately identify, locate and update your inventory levels. E-Max ERP enables you to fulfil all your stock requirements, reduces excess inventory held, and improves your overall inventory accuracy.Forecast Usage and Orders

Predicting what’s ahead can be challenging but E-Max ERP can help you forecast usage and orders for both raw materials and sub-assembled parts. Analysing historical sales and stock data, E-Max identifies trends and helps forecast future demand, allowing you to optimise your inventory levels, reduce waste, and improve your production planning.Sales Management and Forecasting

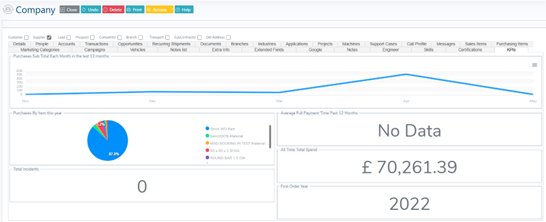

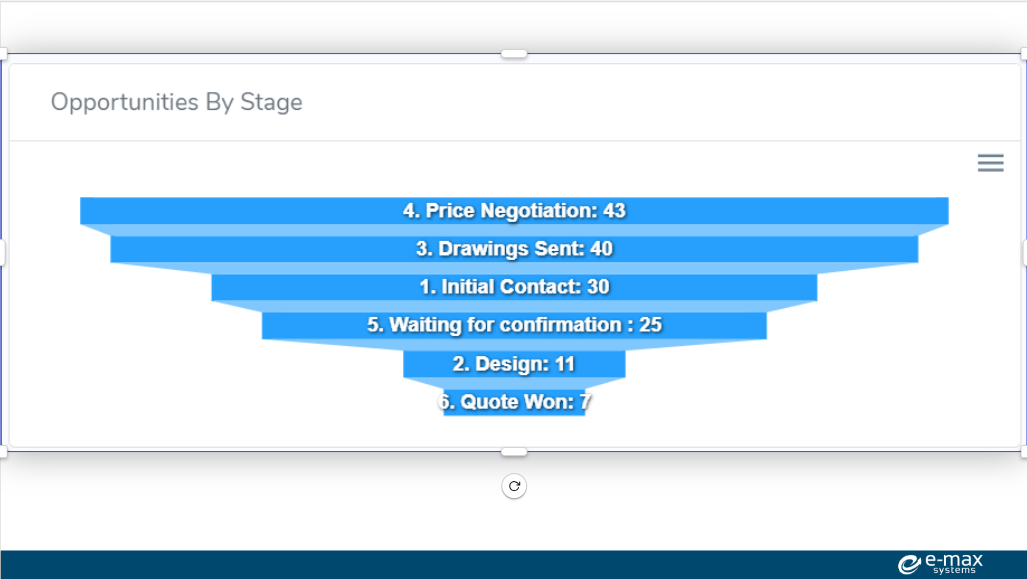

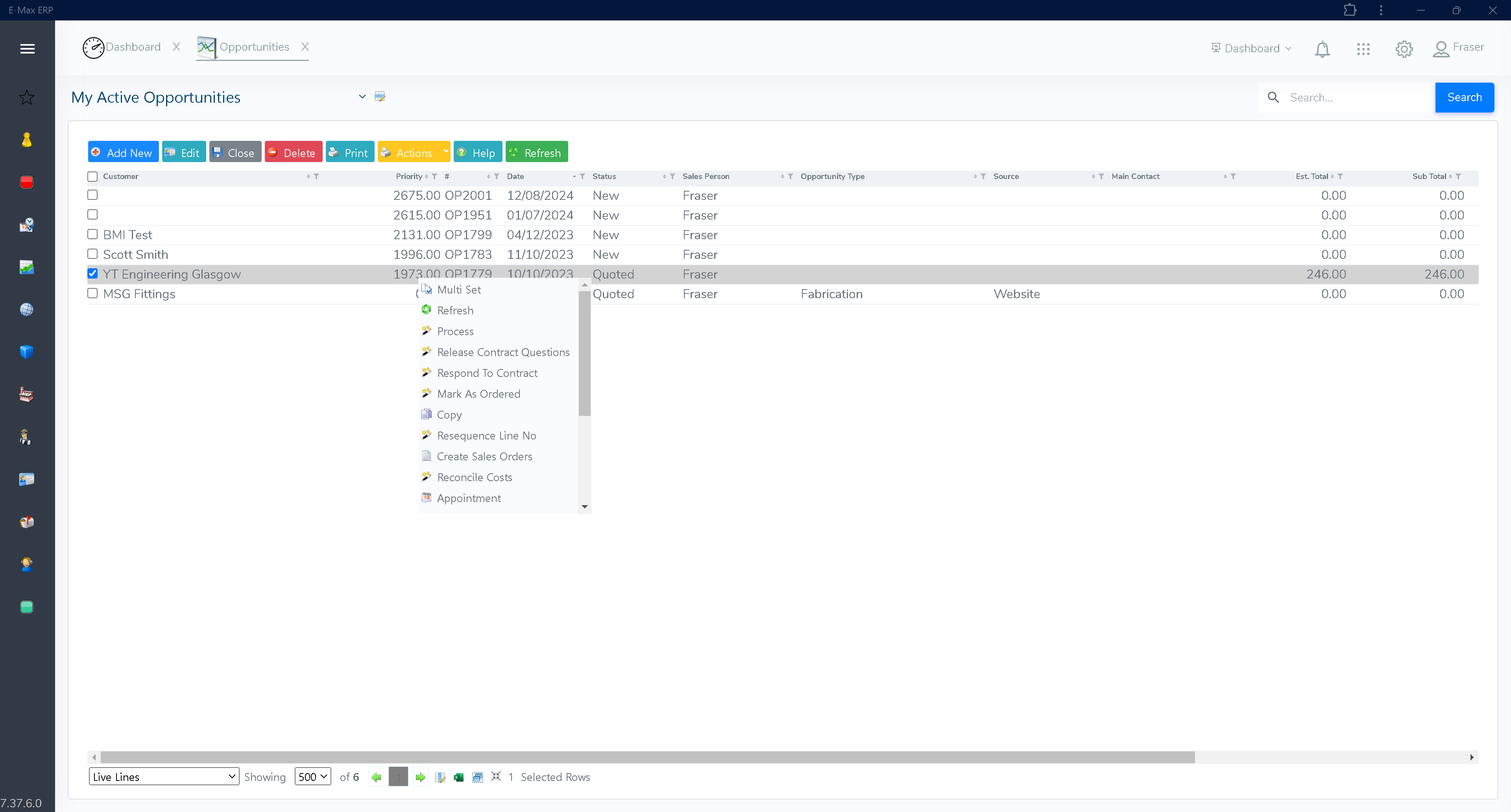

Use E-Max ERP to gain insights into your sales performance, customer behaviour and market trends. In conjunction with historical sales data, E-Max ERP can help you spot opportunities, identify trends, and improve your sales forecasting accuracy.Manage your Production

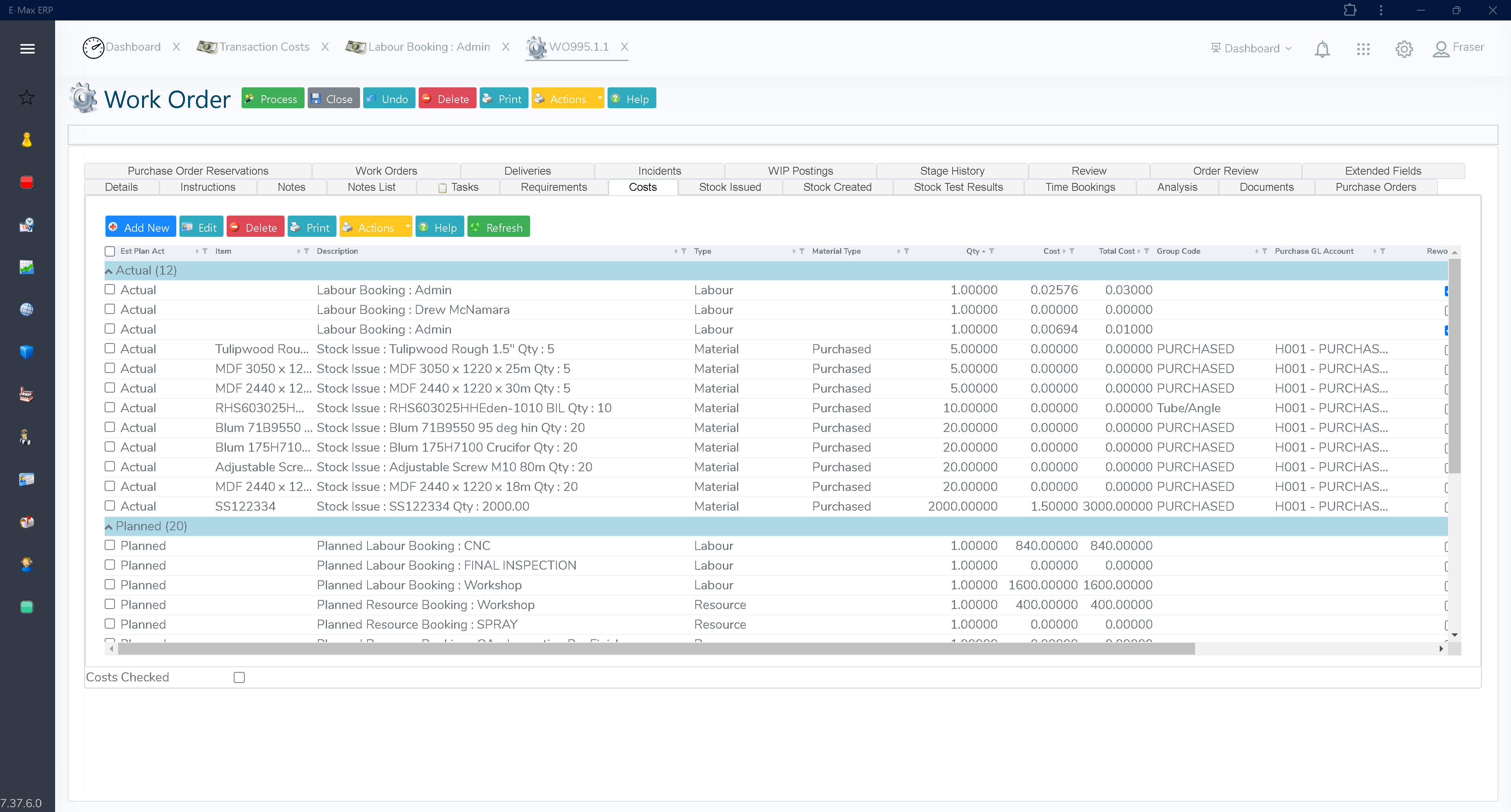

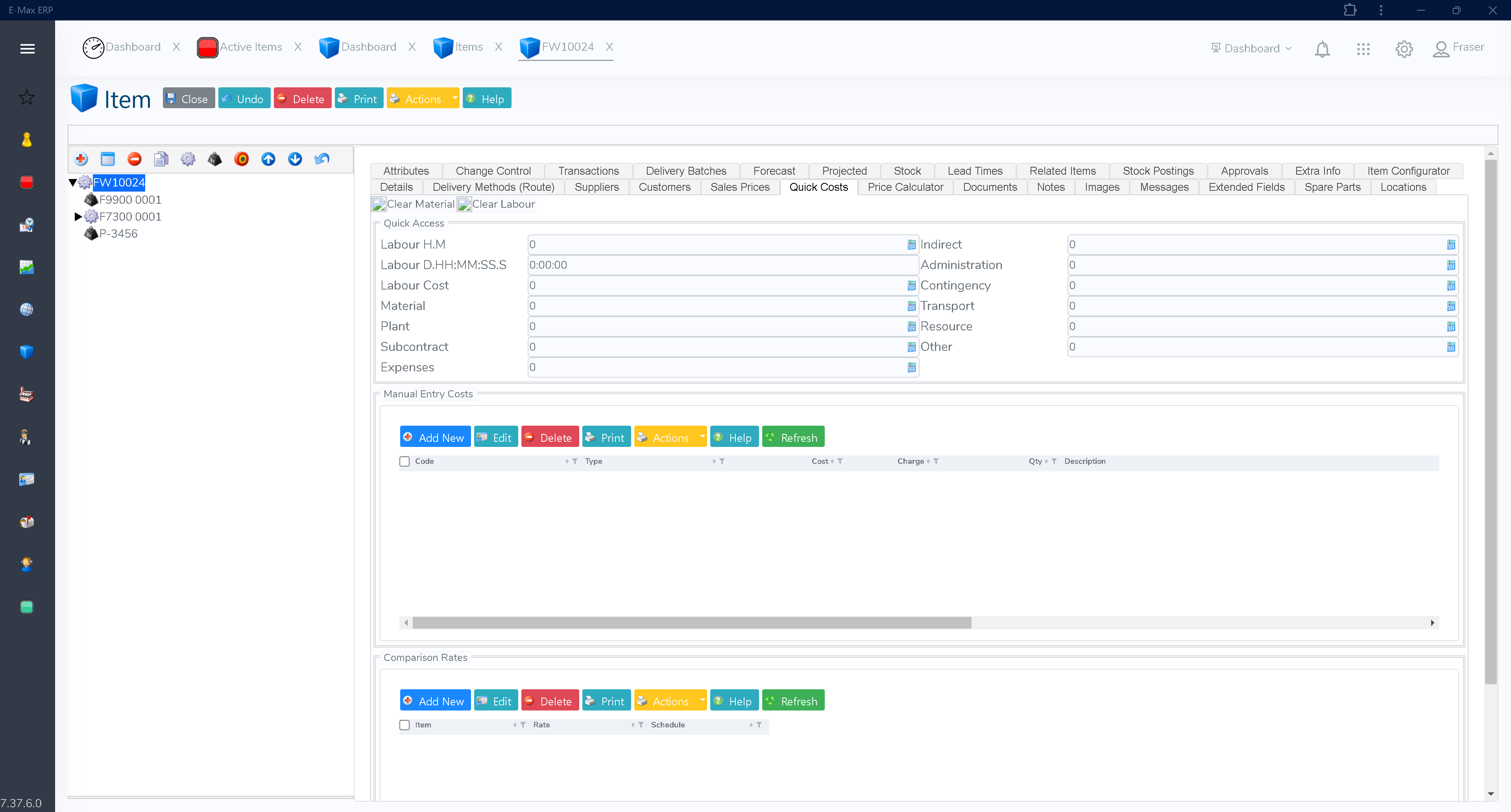

Get real-time visibility into every step of the production process, from sales order to work order processing, routing and scheduling, order fulfillment, and product costing. With this information you can optimise your production processes, reduce lead times, and improve your overall production efficiency.Control Your Costs

Ensure costs don’t spiral with the real-time visibility and reporting of costs E-Max ERP offers. Cost control is significantly easier with E-Max by automating processes, better stock management, including waste, reducing non-productive time and increasing efficiency across your operations.Warranties & After Sales Servicing

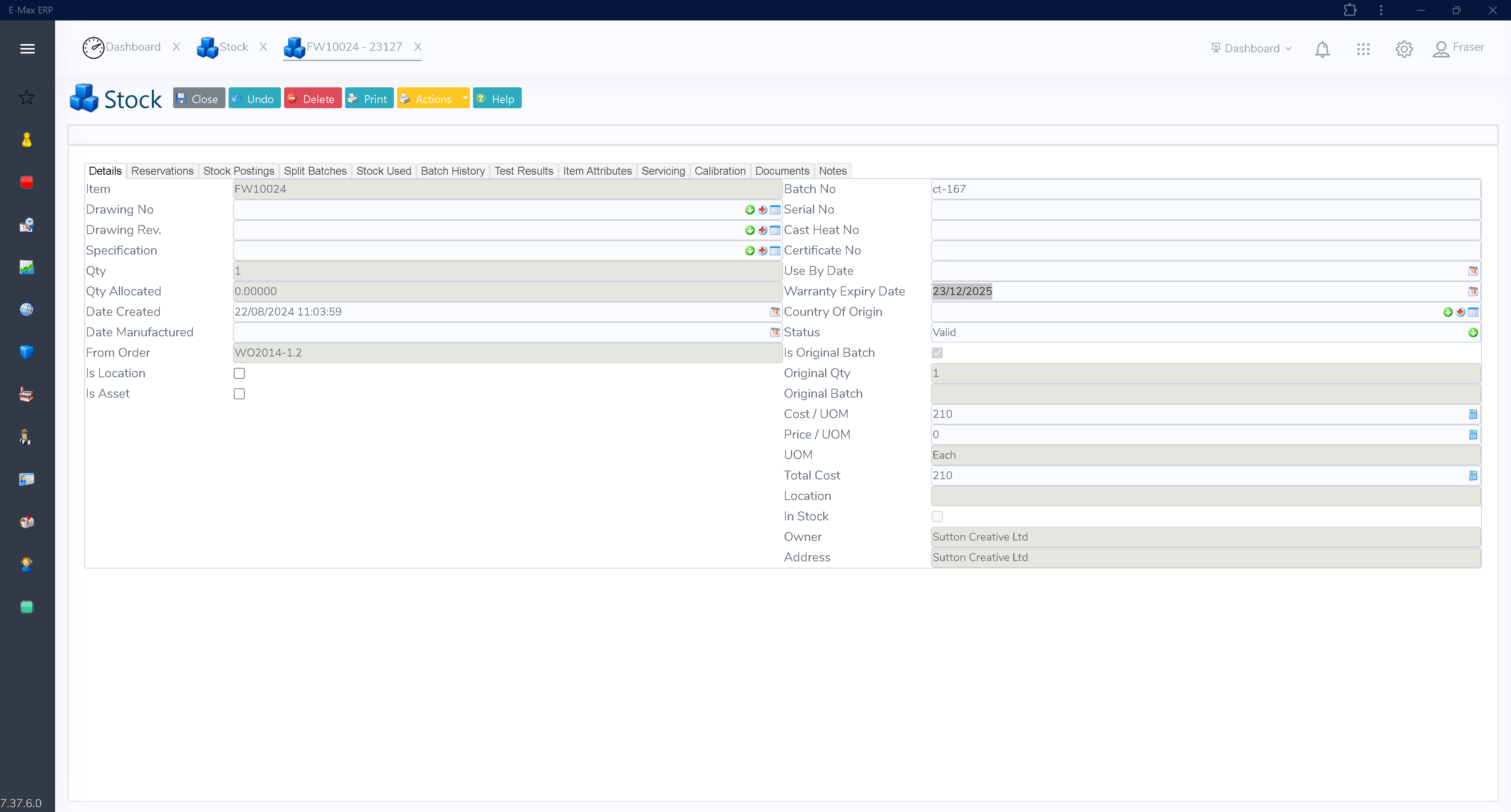

Improve your warranties and after-sales servicing with E-Max ERP. Apply warranties to every finished good, track claims made by customer and individual finished item. Streamline your processes such as on-site service, and return-to-bench (RTB) to reduce warranty costs and increase customer satisfaction.Contact and Account Management

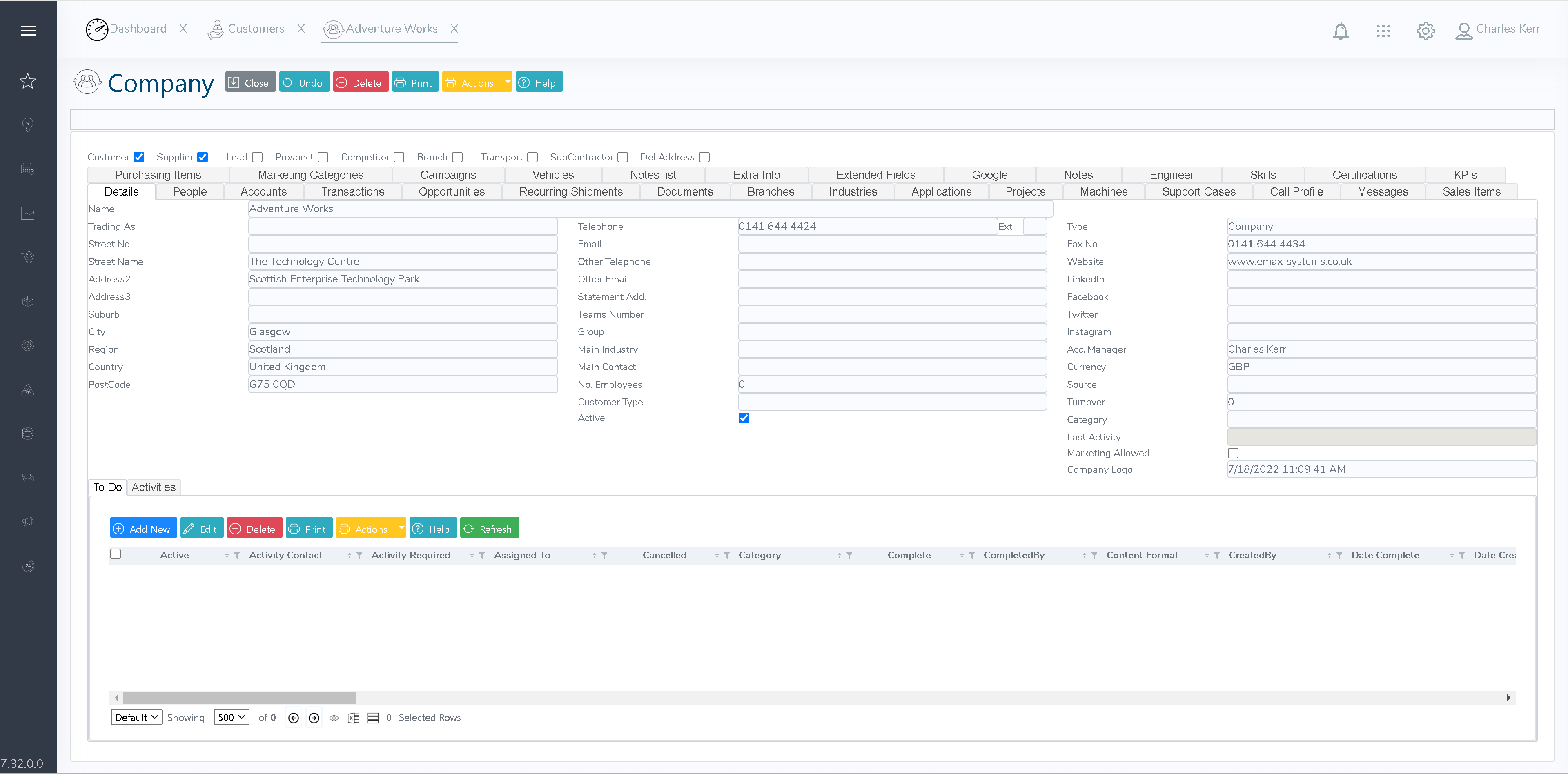

Keep all your customer information organised and accessible in one place. Capture details, track interactions, and maintain a comprehensive view of your customer base for targeted marketing and personalised service.Workflow Automation

Instantly convert sales quotes to orders, raise purchase orders from works orders and create production schedules. By integrating sales, purchasing, inventory and production, jobs flow seamlessly through the system without any duplication or manual error.Quick Quotes

Generate quick quotes for prospective or existing customers. Include images and descriptions in a clear easy to read format and send electronically in just a few clicks. Leverage the data within E-Max ERP to provide fast, accurate and efficient responses to RFQs and win more business.Inventory Tracking

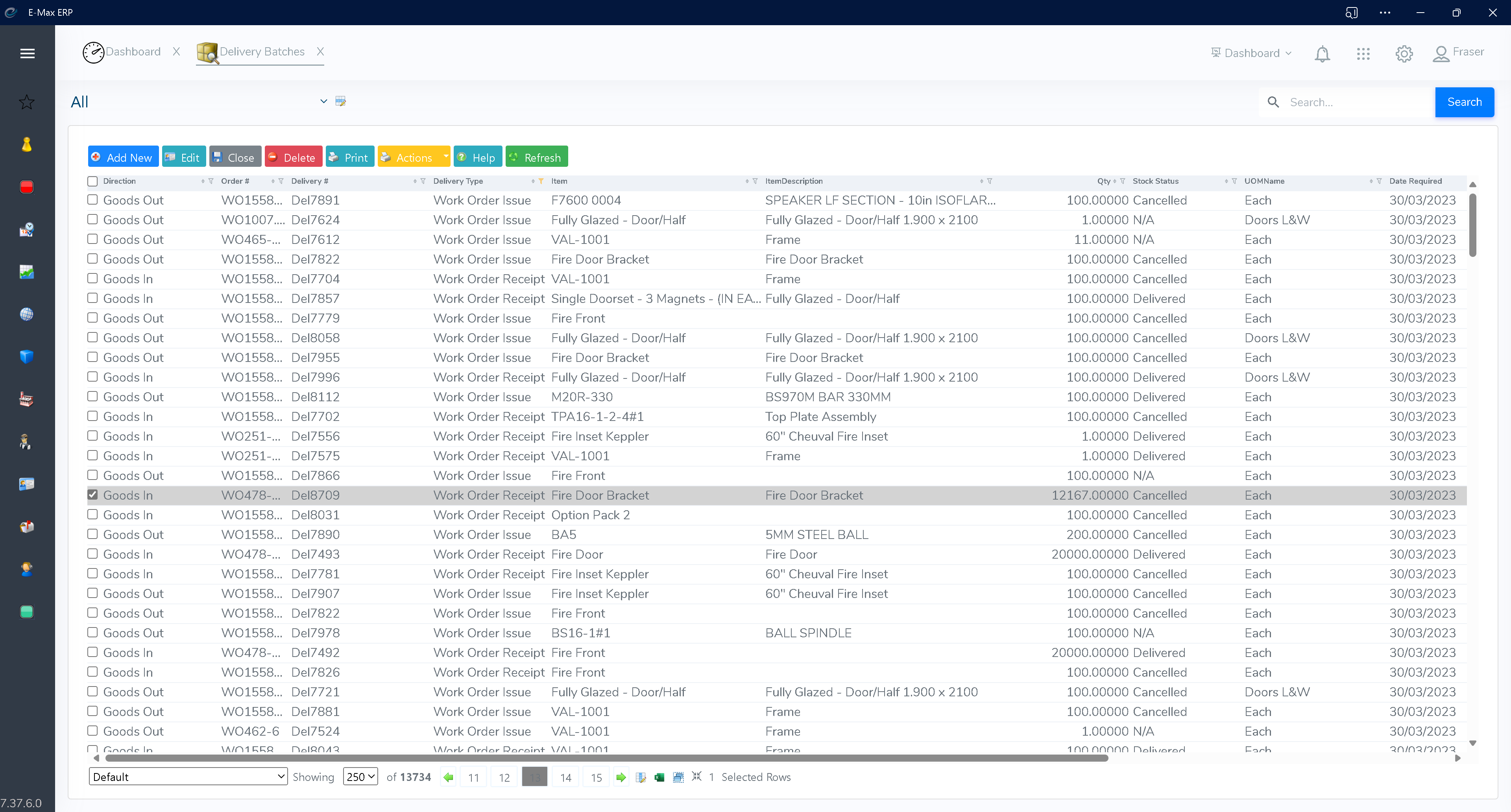

Monitor the flow of goods in and out of the warehouse with E-Max’s stock control system. Track what materials you have, the quantity of each, location within the warehouse, and any changes in stock levels due to sales, returns, or new arrivals, all in real time and visible from any area of E-Max ERP.Bill of Materials (BOM)

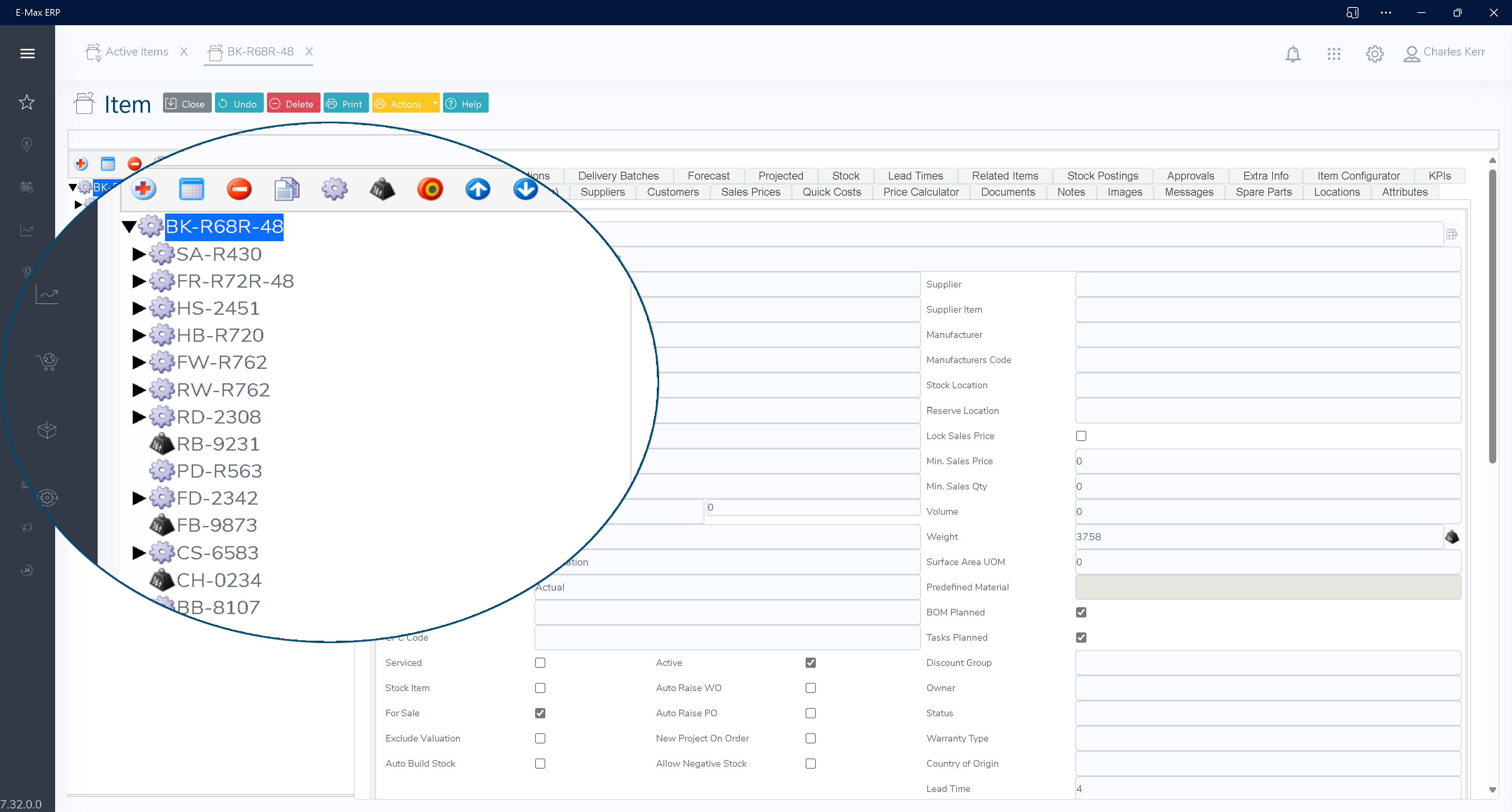

E-Max’s bill of materials allows you to accurately define all the components, materials, parts, subassemblies and quantities required to manufacture a finished product. Starting with the finished product at the top, its hierarchical structure allows infinite multi-level BOMs of unlimited size. Save time by duplicating existing BOMs, use the tracking history to record revisions (ideal for audit purposes), and import BOMs from other software packages, including Excel and CAD packages. Included in E-Max ERP’s BOM is a standard item configurator.Full Traceability

Easily track and manage raw materials, components, and finished products from supplier, through the production process, and onto the end customer. E-Max ERP’s traceability functionality automatically records and archives all data, including materials in and finished items, producing appropriate documentation, such as certificates of conformance, non-conformance or incident reports, and test certificates.Used and Trusted by Manufacturers

Item Revisions and Version Control

Achieve clear visibility and control of each different version of a BOM or route. As part of E-Max’s product lifecycle management, all revisions are tracked, with the current version being stored on the item or part master.Revision Control

Manage product updates, design modifications or improvements with E-Max’s Revision control. Once approved, our Version Control records a full history of revisions with every drawing change stored in E-Max's Drawing Register.Works Order Management

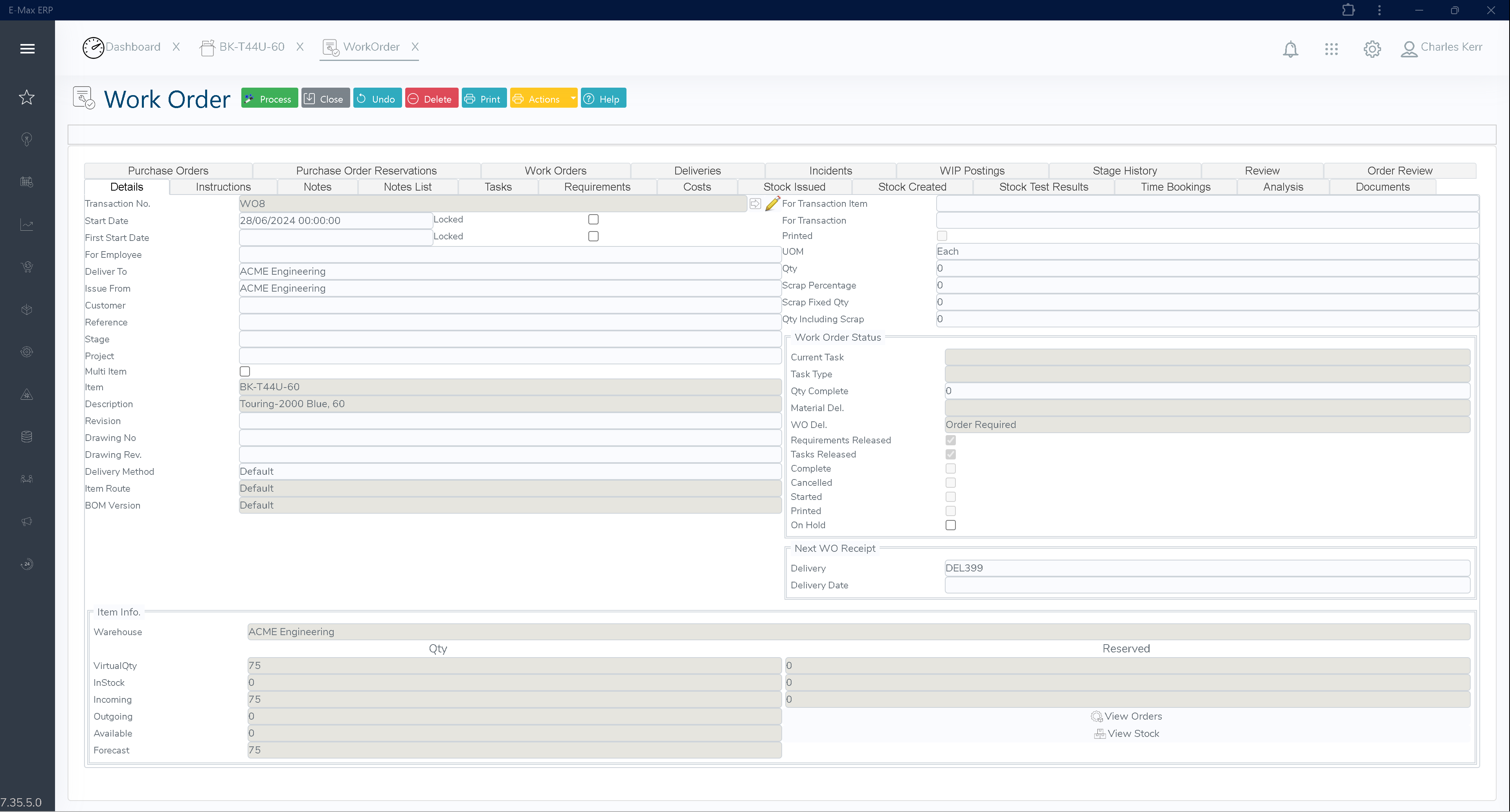

Generate works orders in a single click with E-Max ERP and keep your production moving. Guide your production team, coordinate your resources and ensure every job is manufactured to a quality standard and schedule. E-Max ERP supports multi-item works orders, allowing for nesting and by-products being returned to stock.360° Reporting Across your Business

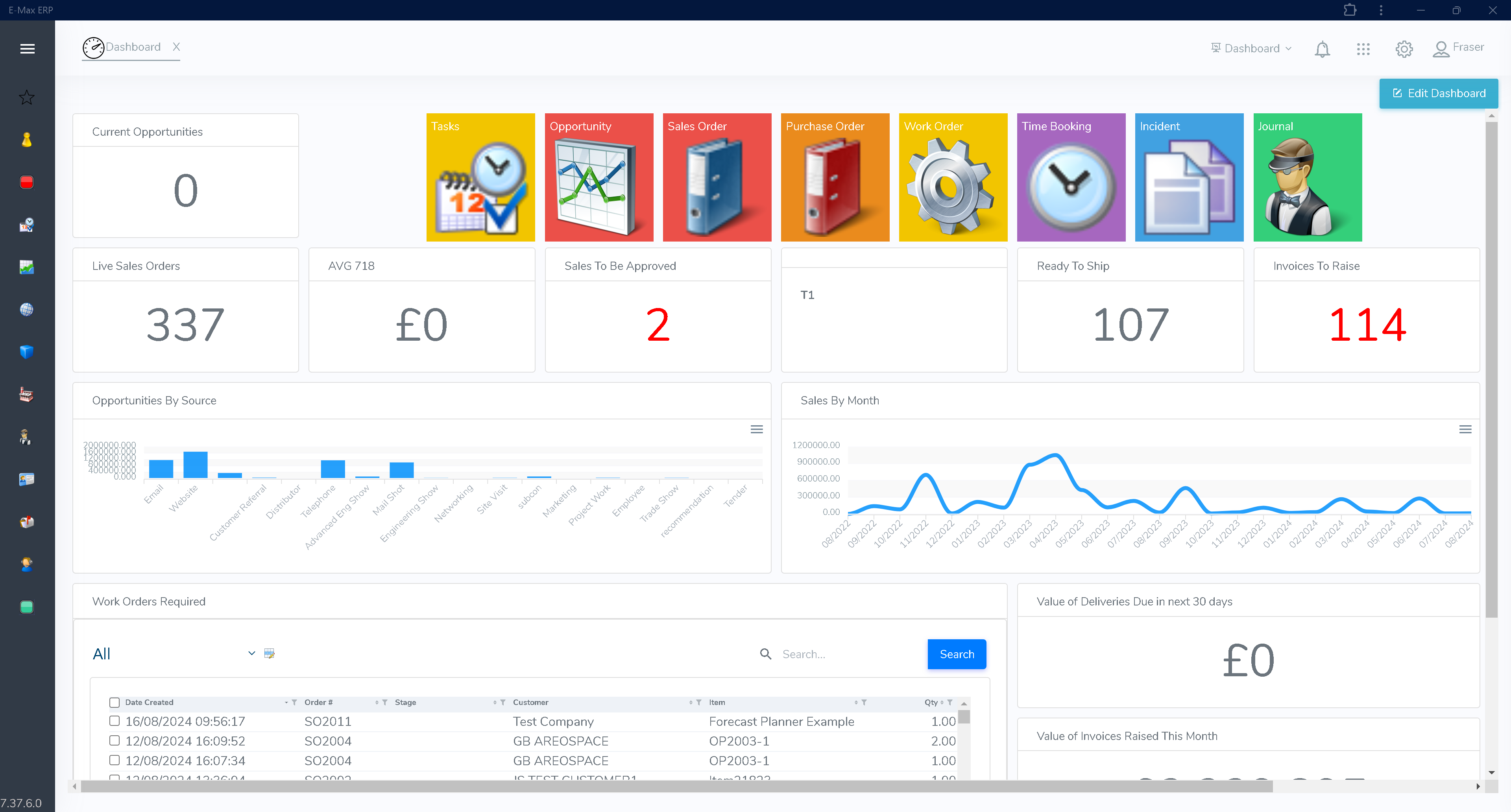

E-Max ERP provides powerful interactive dashboards and a suite of reports meaning you can access accurate, real-time information at any time, in a format that best suits you. Whether it's data on stockturns or number of units manufactured, the drill-down feature on every graph, chart or visual provides you with the answers you need, instantly.Wireless Warehouse

Optimise picking and packing and reduce the time spent on these. Use any handheld device capable of barcode scanning to verify items and record their location. E-Max ERP allocates all the deliveries, inbound and outbound, for a day or shift, to allow the warehouse team efficiently work through these, whilst recording locations. This can also be used for quick stocktakesSupplier Pricelists

Automatically apply supplier pricelists, including quantity break prices and lead times, and make the most effective, informed purchasing decisions. Pricelists are updated automatically as responses to RFQs are received or can be updated in bulk when new pricelists are received.Take Control of your Shop Floor

E-Max ERP’s SFDC provides manufacturers with a cutting edge but inexpensive means of collecting key data directly from the shop floor. It’s a simple yet effective way of capturing real time, accurate data on labour, resources, and job costs, and can save time and manufacturing costs, reduce errors and increase productivity on the shop floor.Comprehensive Supplier Management

E-Max ERP keeps your supply chain moving smoothly by allowing you to effectively manage your supplier relationships. Set supplier ratings, approval status and credit limits and easily identify reliable and efficient suppliers. View the full history of transactions with each supplier.E-Max ERP Software

offers all of this and more:

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)