Warehouse Management

Every company with a requirement for stock control will benefit from a warehouse management system. Our modern WMS enables your business to effectively manage your inventory, fulfilment, shipping and delivery, allowing you to improve overall operational efficiency and productivity, and maximise warehouse space.

Inventory Tracking

Monitor the flow of goods in and out of the warehouse with E-Max’s stock control system. Track what materials you have, the quantity of each, location within the warehouse, and any changes in stock levels due to sales, returns, or new arrivals, all in real time and visible from any area of E-Max ERP.Forecasting and Demand Planning

Accurate stock control requires forecasting future demand for products. Use E-Max reports and dashboards to analyse historical sales data, seasonal trends, and market insights to make informed decisions on the levels of stock to keep at hand.Reorder Points and Safety Stock

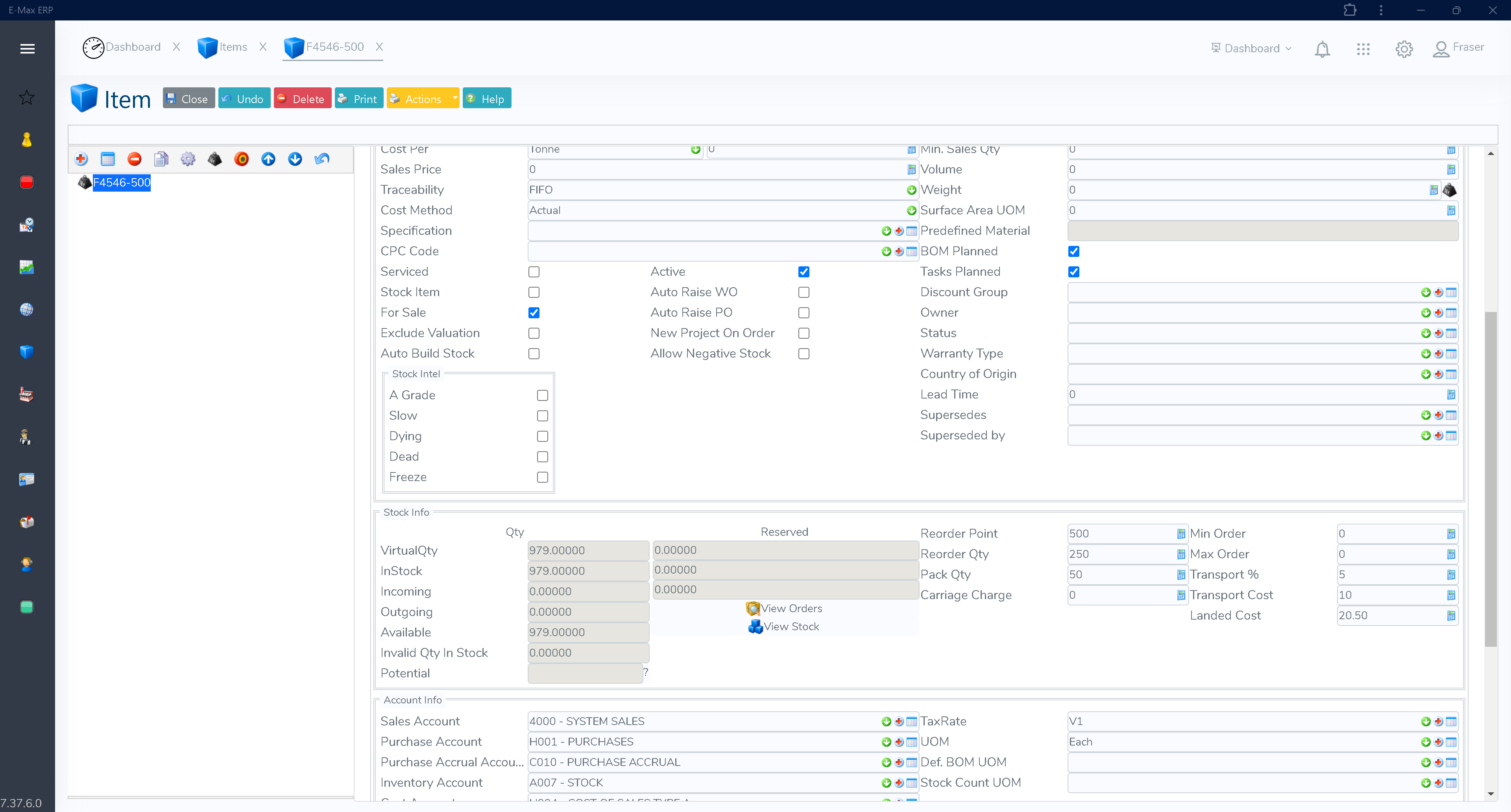

Predefine inventory levels and create rules to automate stock replenishment. Choose whether to include an extra quantity of inventory as safety stock to guard against unexpected demand fluctuations or supply chain disruptions.Maximise Use of Space

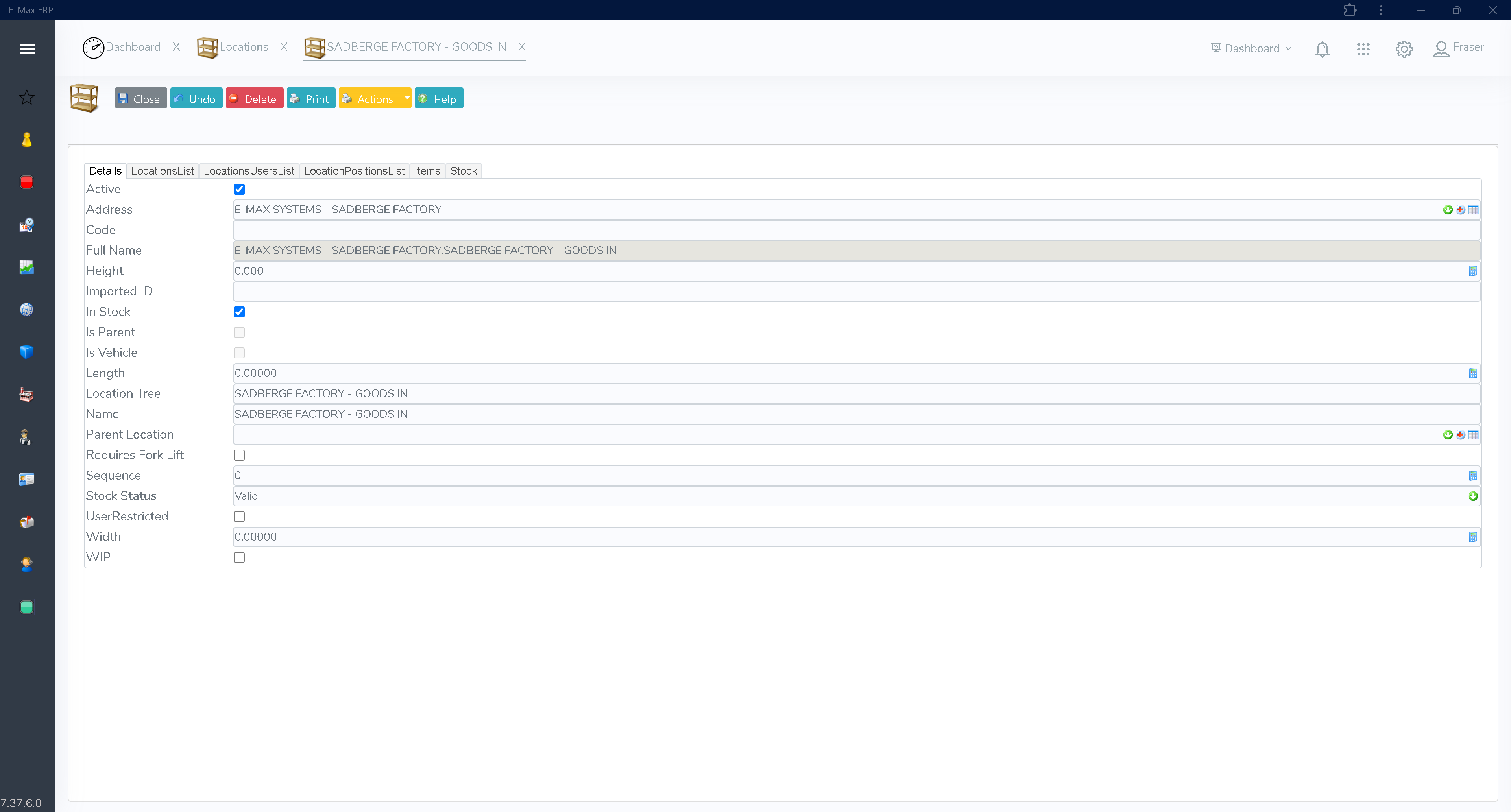

E-Max’s warehouse capacity management allows you to optimise the allocation of storage space for your stock, based on usage reports, characteristics including volume and weight, and accessibility requirements. This helps maximise warehouse space utilisation and minimise operational inefficiencies.Automate Workflows for Greater Inventory Accuracy

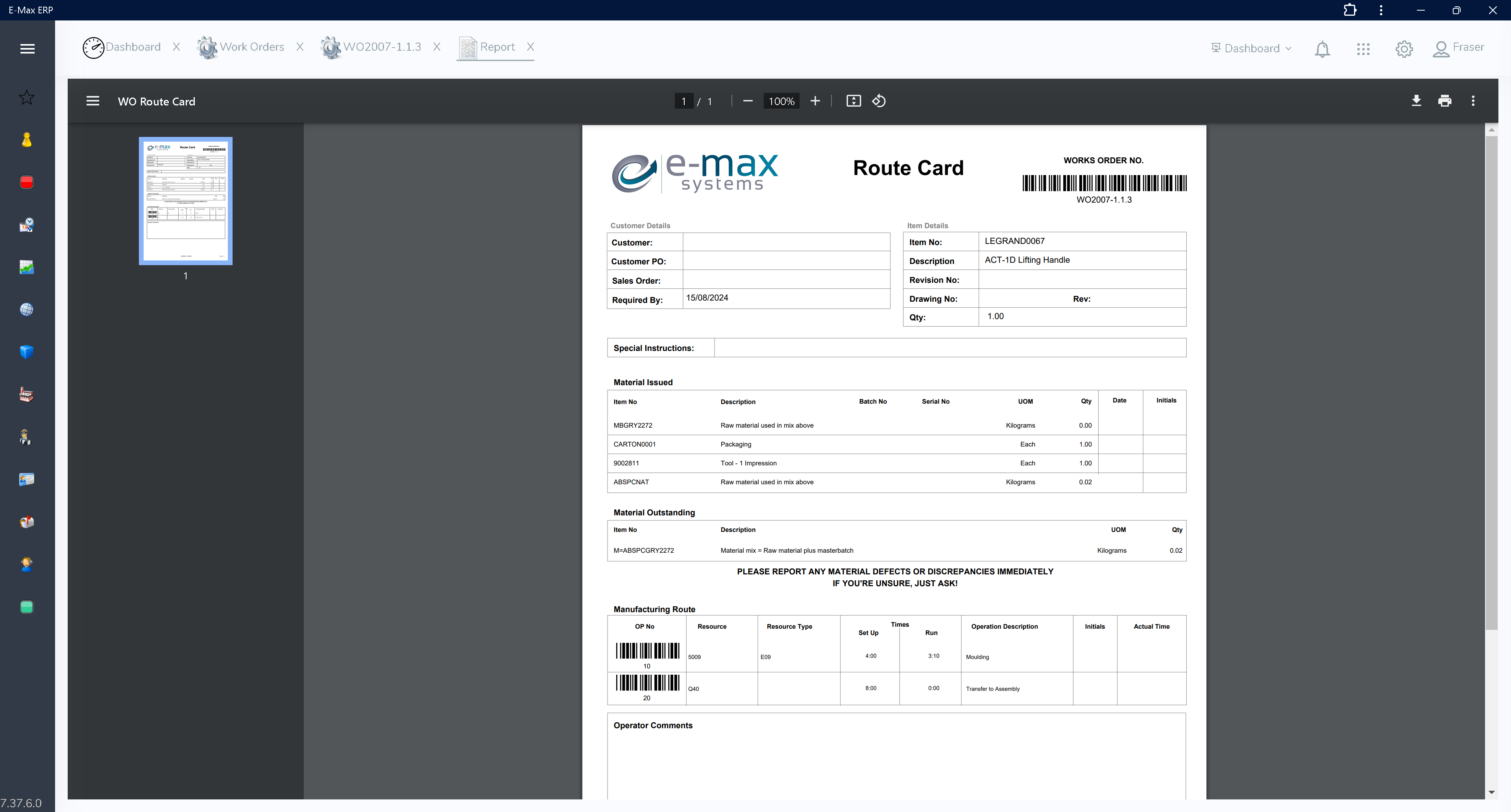

Reduce inventory errors and improve productivity with E-Max’s automated workflows and data collection, using tracking systems such as barcode scanning or RFID. Create labels, auto-send stock updates to customers and suppliers, generate task lists for incoming/outgoing stock and produce picking lists.Inventory Analysis

Use E-Max reports and dashboards to analyse inventory turnover ratios, lead times, and stock movement patterns. From there slow-moving or obsolete items can be identified and informed decisions made about discontinuation or promotions.Wireless Warehouse

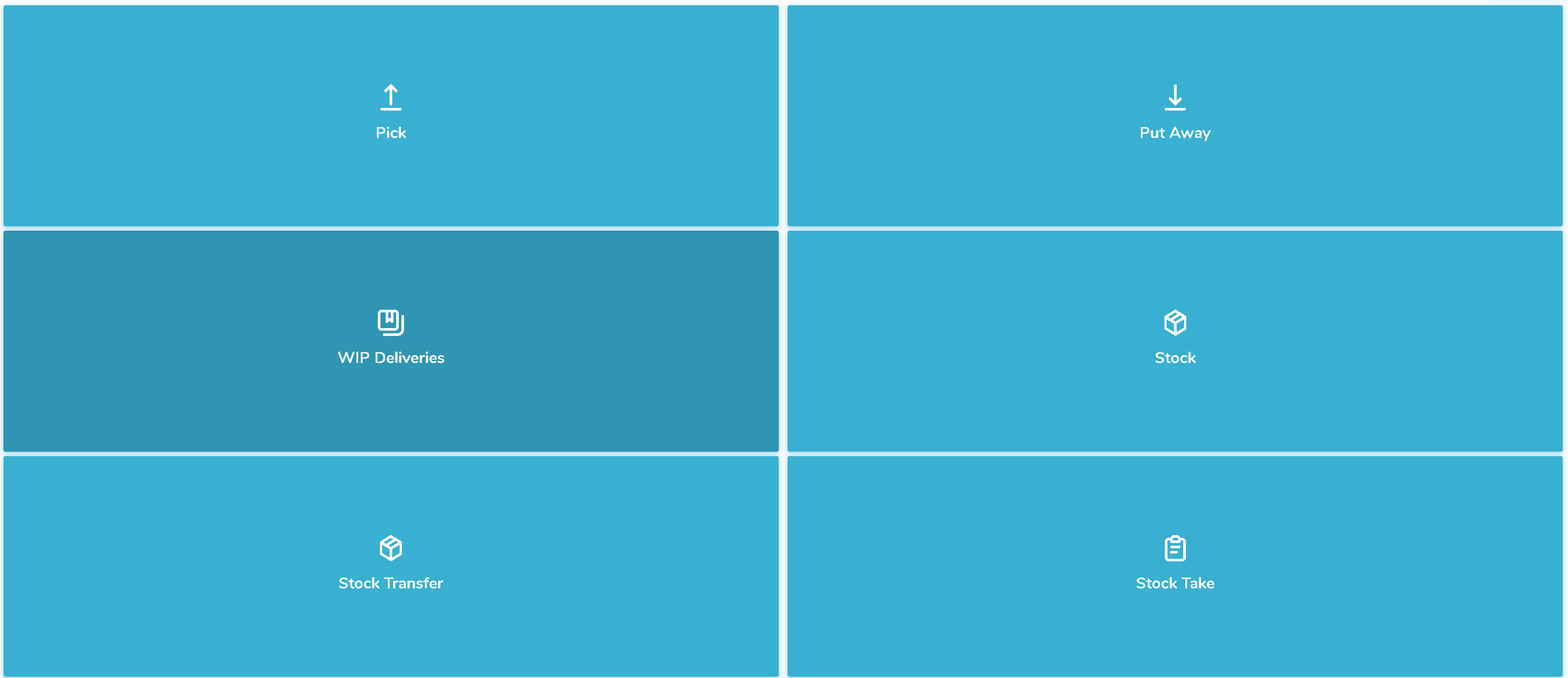

Optimise picking and packing and reduce the time spent on these. Use any handheld device capable of barcode scanning to verify items and record their location. E-Max ERP allocates all the deliveries, inbound and outbound, for a day or shift, to allow the warehouse team efficiently work through these, whilst recording locations. This can also be used for quick stocktakesQuarantined Stock

The multi-location nature of E-Max ERP’s warehouse system allows you to specify locations for quarantined stock or stock that requires inspection.Conduct Efficient Stocktakes

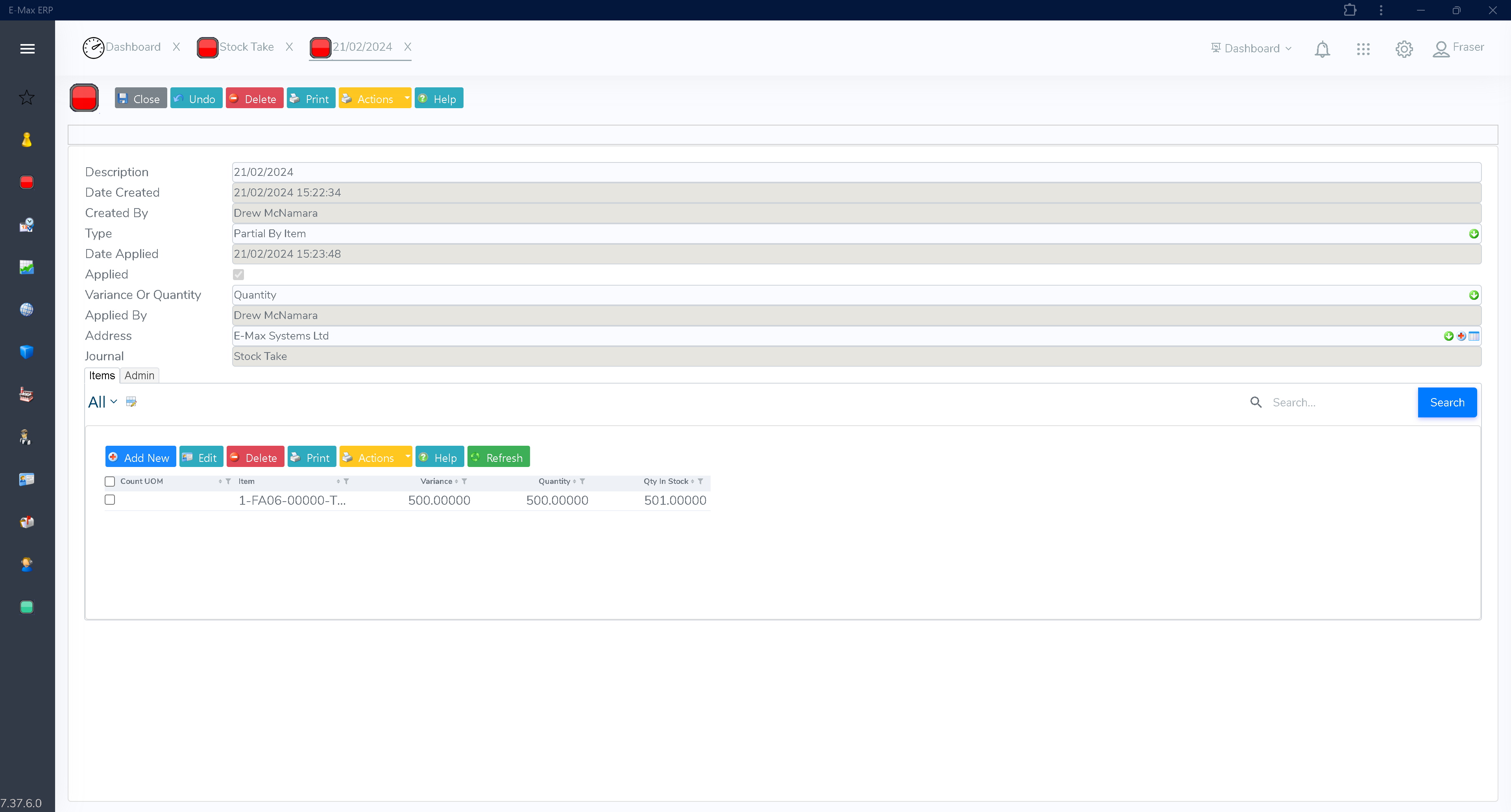

See your actual stock balances quickly. Simply scan the location, each item’s barcode and confirm quantity at that location to identify any variances in quantities.Full Traceability

E-Max ERP tracks materials in real time across your operations, not just in the warehouse. Track by batch, serial or lot numbers, or by date, including First In First Out (FIFO), Last In First Out (LIFO), and Use By.Multiple Locations and Multi-Warehouse

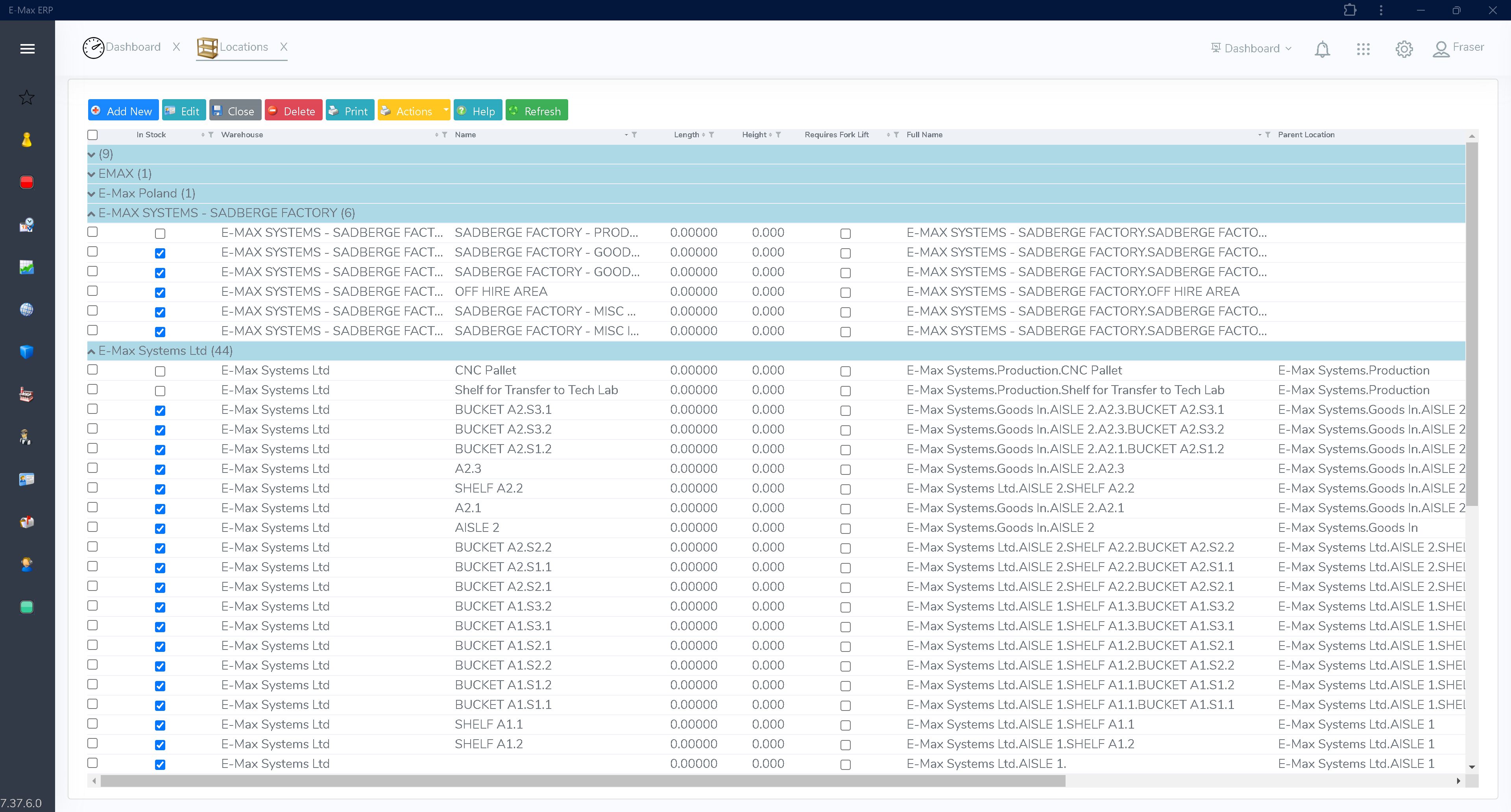

Define and manage bin locations within your warehouse, from site, aisle, shelf, bin, to location on shelf to optimise use of space and gain easy access to stock. Plus, if you have more than one warehouse, E-Max supports different addresses to ensure materials are issued to the appropriate site.Pick, Pack & Ship Automation

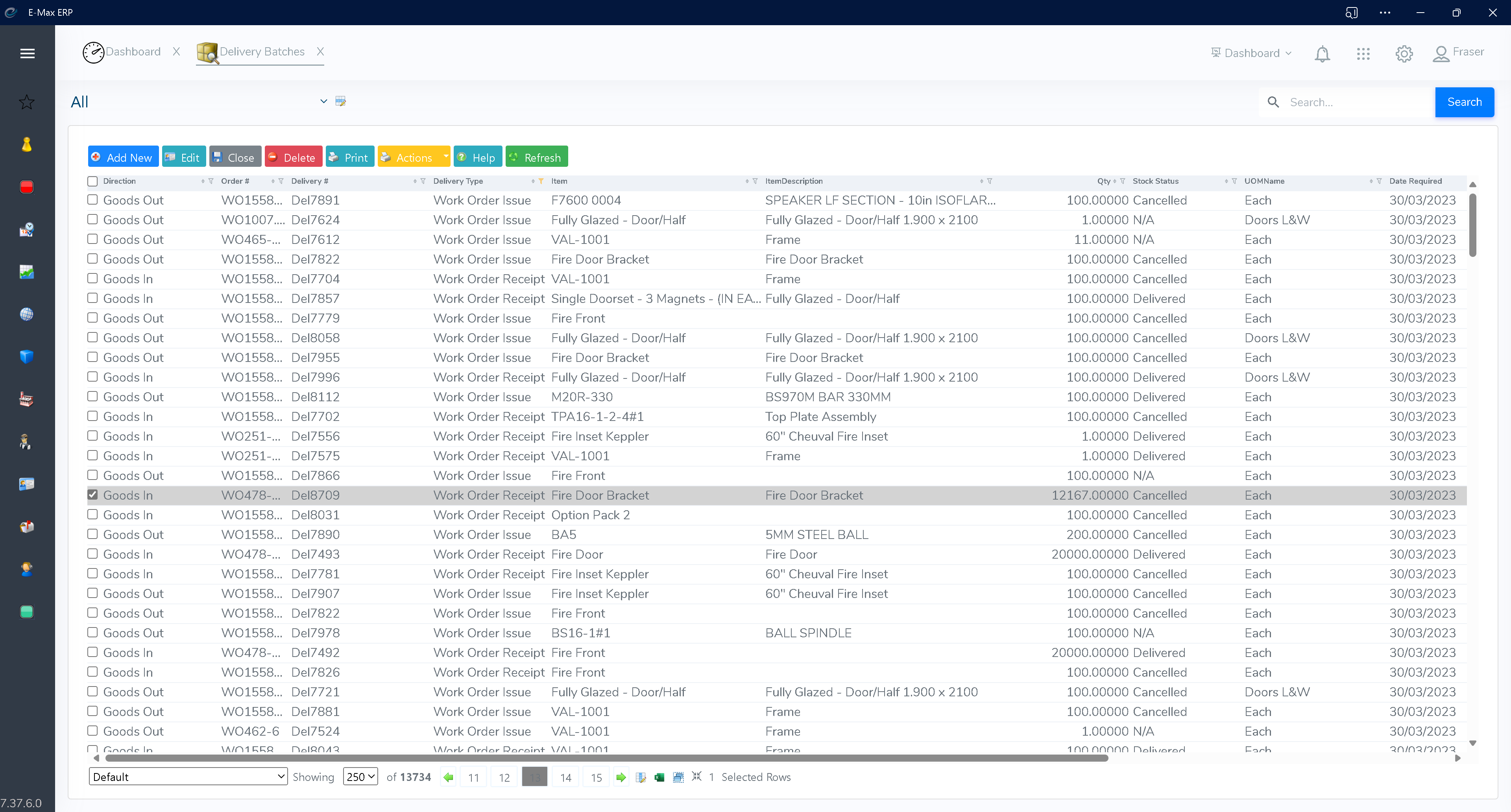

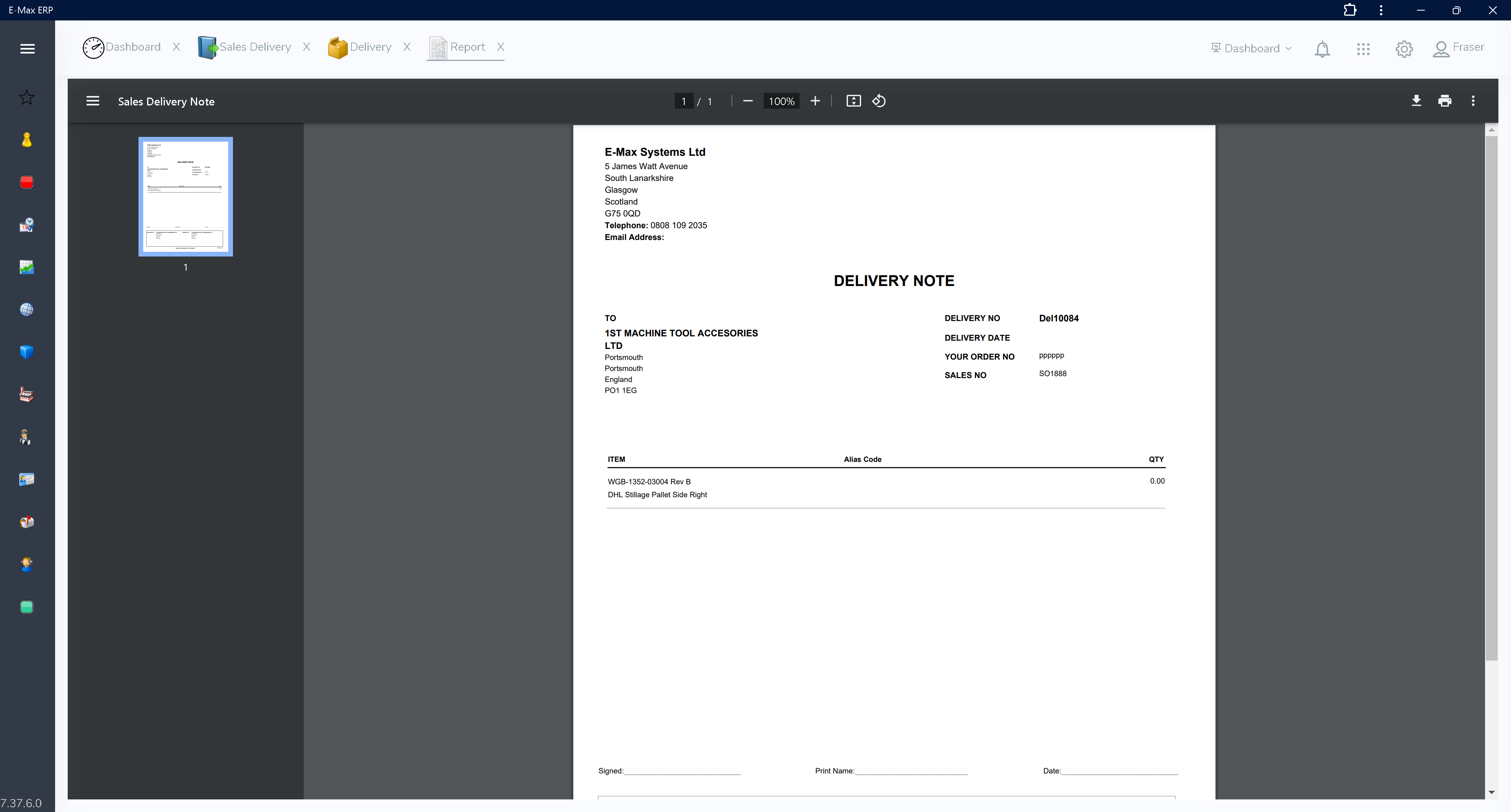

E-Max ERP automates the pick, pack, and ship processes, reducing manual errors and increasing efficiency. Pick lists, packing slips, and shipping labels can be generated automatically from orders, minimising delays and improving order accuracy.Kitting

Streamline your picking and packing process further by creating kits. Use E-Max’s BOM to specify components and quantities and store them in easily accessible locations under a separate SKU or item number.Goods In

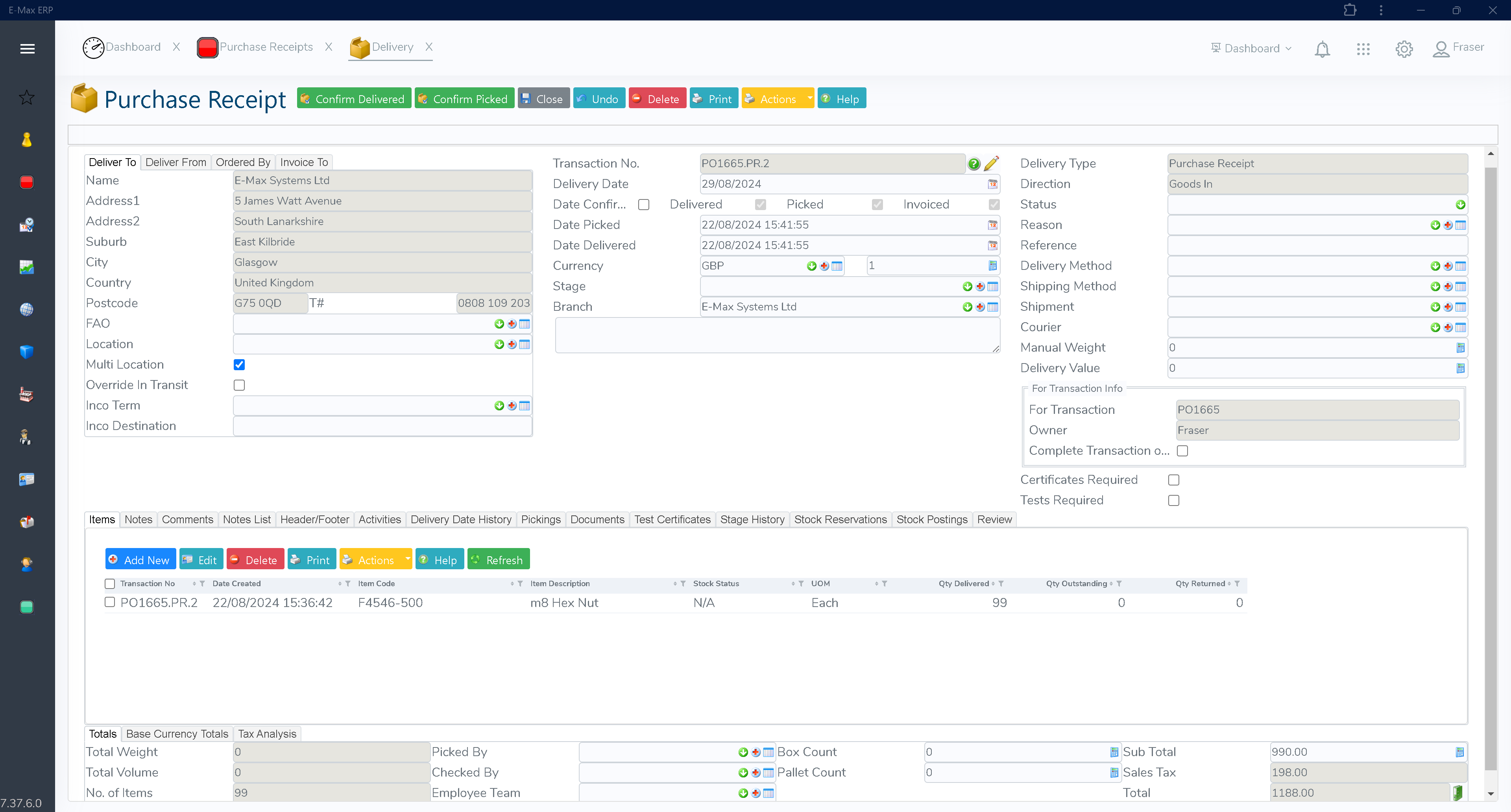

Upon receiving goods into your warehouse, you can easily reconcile goods against the PO in E-Max ERP. Record quantities, weight, volume, batch, lot or serial numbers, inspection reports of damage or quality issues and any other relevant information, including any documentation such as images, descriptions, drawings, certificates, and testing results. Once goods are received in E-Max ERP, notifications will be sent to relevant departments and stock levels updated.Returns Management

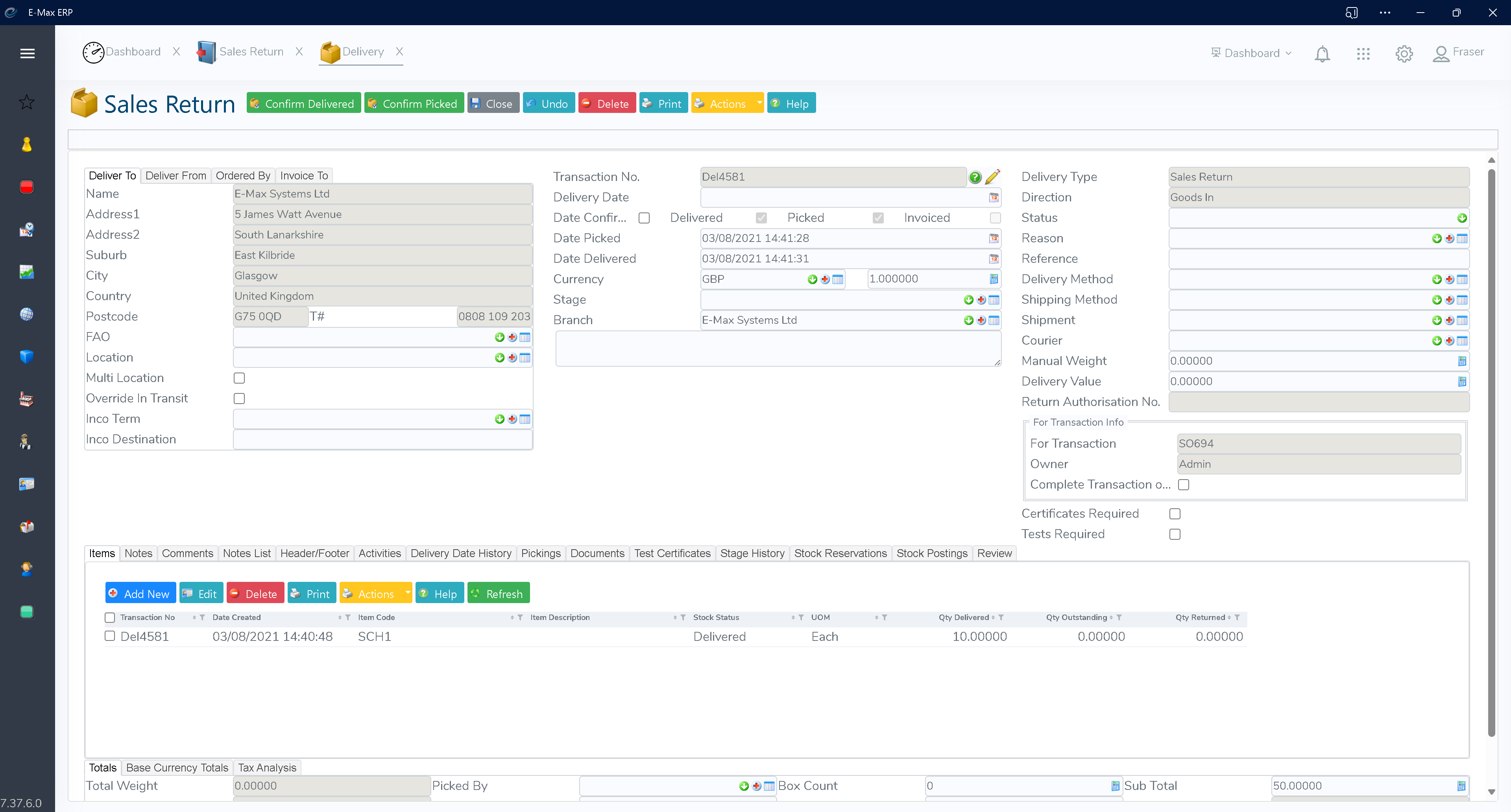

Effectively manage your returns process and minimise the impact of returns. From return authorisation, receipt of goods, inspection reports to the final outcome, whether it’s restocking, refurbishing, repairing or disposal, E-Max ERP allows you to record all the details and communicate throughout the process with customers.Landed Costs for Imports

E-Max ERP offers full capture and analysis of landed costs, allowing you to allocate all costs, including transport, import fees, tax and customs fees.EDI (Electronic Data Interchange) Compatible

Avoid problems such as miscommunication, human errors and incorrect shipments with standardised data transfer. Moving to an electronic platform allows automation of slow manual processes and removal of paperwork.Shipping

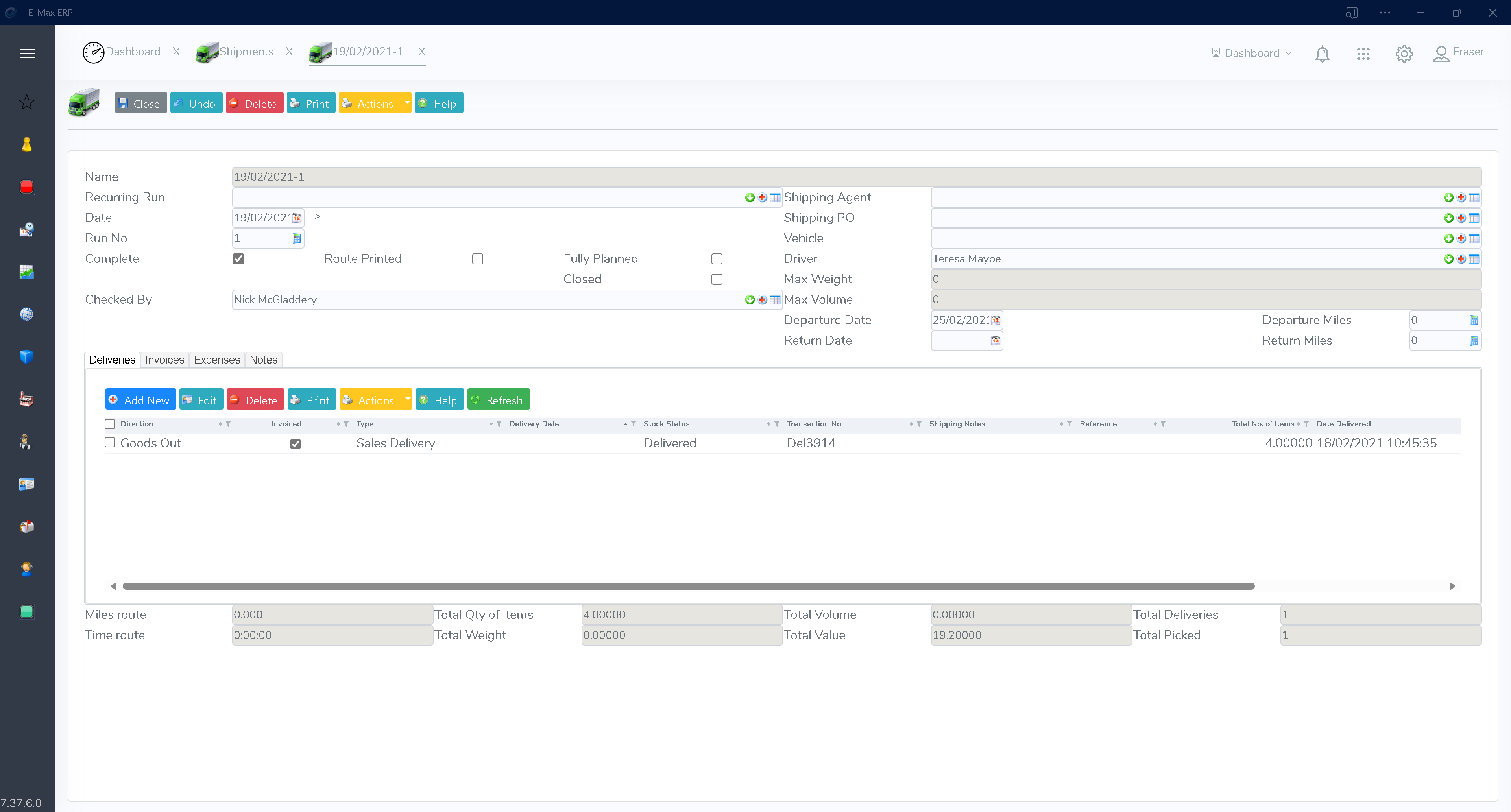

Manage shipping by grouping multiple deliveries into one shipment and easily applying the same status to every delivery.Backorders and Split Deliveries

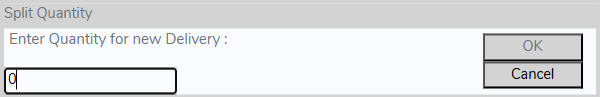

With E-Max ERP you can manage backorders and split deliveries. Customers who accept split deliveries can be noted as such and deliveries then split into multiples. If a customer has a change of mind, further deliveries can be easily cancelled. All date is recorded in E-Max and available for review at a later date.Calculate Weights of Finished Products

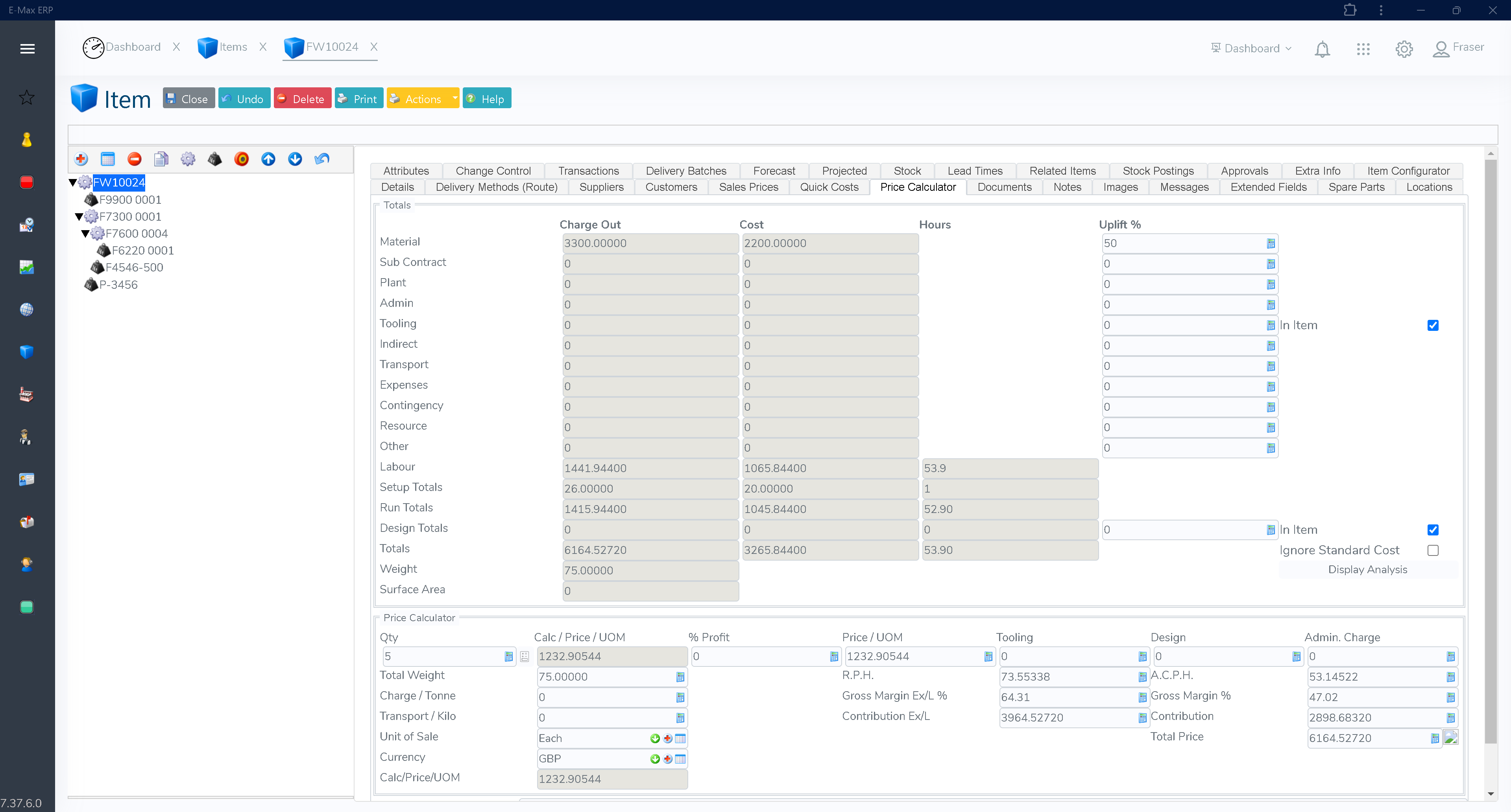

E-Max ERP calculates the finished weight of your manufactured products so these can be safely stored in your warehouse before being delivered to a customer or used in production of another product.Time to optimise your warehouse efficiency?

We can help

E-Max ERP Software

With E-Max ERP you can easily manage

.png)

.png)

.png)

.png)

.png)

.png)