Why Flexible Scheduling Matters in Modern Manufacturing

Flexible scheduling is essential for manufacturers who face changing priorities, varying specifications and shifting customer demands. A flexible production scheduling system improves visibility, protects delivery dates and helps teams respond confidently to real-time changes. This article explains why scheduling flexibility matters - and how tools like the E-Max ERP Scheduler support more agile, reliable shop floor operations.

Manufacturing rarely runs in a straight line. Customer requirements change, materials arrive late, machines go offline, and new jobs can appear with little notice. For many engineering and manufacturing businesses, particularly those producing work on a Make to Order (MTO) or bespoke basis, the ability to adapt quickly isn’t just helpful - it's essential.

This is why flexible scheduling has become such a critical capability in modern manufacturing. Whether your operation manages high-mix/low-volume work, varied batch sizes or complex, customer-driven specifications, a flexible production scheduling system gives you the visibility and agility needed to keep work flowing, maintain delivery performance, and maximise your available capacity.

This article explores why scheduling flexibility matters, how it supports better operational outcomes, and the role tools like E-Max ERP’s Scheduler can play in improving control across your shop floor.

Production Environments Change Fast - Your Schedule Must Too

Even the most carefully planned schedule can shift rapidly. Supply chain delays, urgent customer requests, staff availability and unexpected downtime all force production teams to rethink their plans on a regular basis.

A modern, flexible scheduling system enables planners to:

- Reschedule work instantly

- Move operations between machines, work centres or shifts

- See the impact of changes before committing

- Provide teams with a continuously accurate, real-time plan

This kind of agility isn’t possible with spreadsheets or wall planners. If you’d like to see how these scheduling capabilities can be supported by more robust production tools, our Production Control and Scheduling features page offers a useful overview.

Better Delivery Performance and Stronger Customer Confidence

On-time delivery remains one of the most important performance indicators for manufacturers, whilst customers expect accurate lead times and reliable communication. . A flexible scheduling system supports this by providing:

- Real-time updates from the shop floor

- Early warnings when a job is at risk

- Scenario planning to test various sequencing options

- The ability to adjust plans around real constraints

This gives customer-facing teams accurate information and allows manufacturers to handle last-minute changes without compromising delivery promises.

Smarter Use of Capacity and Resources

Many manufacturers struggle with overloaded machines, inconsistent labour allocation or bottlenecks caused by outdated planning methods. A flexible scheduling solution built on finite capacity planning offers clear visibility into how work can flow through the business.

With finite capacity scheduling, production teams can:

- Identify bottlenecks before they occur

- Balance workloads across machines and shifts

- Understand how staffing changes affect throughput

- Expand capacity without necessarily increasing overheads

For further practical ideas, why not take a look at our blog on ways to improve shop floor scheduling.

Real-Time Shop Floor Data Powers Better Decision-Making

Flexible scheduling delivers the greatest value when it is supported by accurate, real-time shop floor information. When operators log progress, delays, or completed operations, the schedule updates automatically, giving production planners immediate insight when things are moving ahead or falling behind.

This leads to:

- Improved accuracy of lead times

- Fewer production surprises and less firefighting

- A schedule that reflects true shop floor performance

- Continuous improvement in future planning

Stronger Collaboration Across the Business

A flexible scheduling system provides a shared, reliable source of truth. Sales teams can quote realistic lead times, purchasing departments anticipate demand with more certainty, production teams can allocate labour effectively, and management gains clearer operational oversight.

When every department operates with the same accurate information, communication improves and decisions become more aligned and more effective.

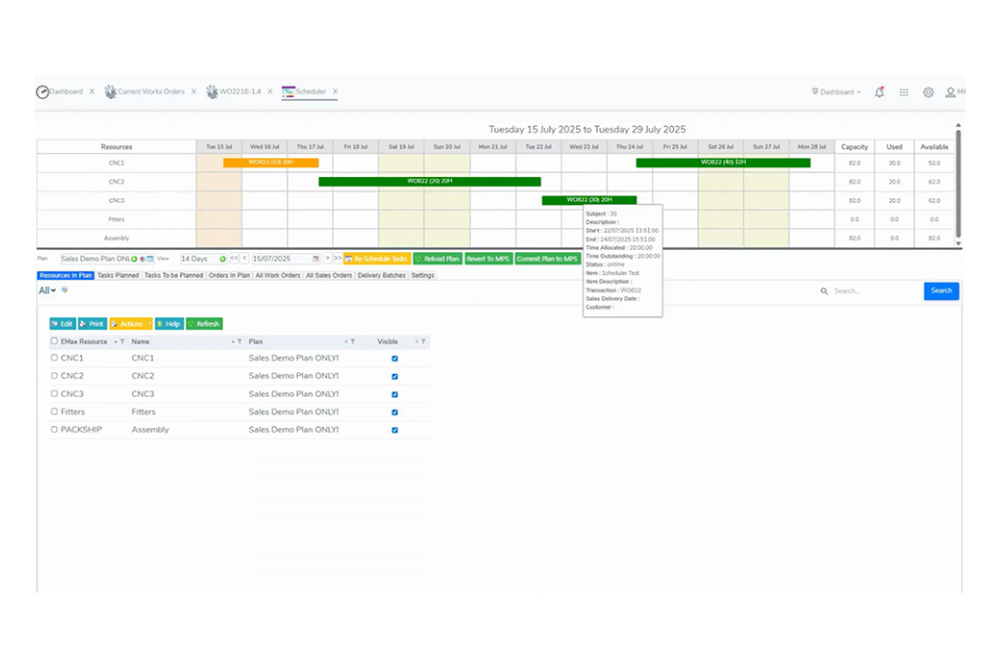

How E-Max ERP’s Scheduler Supports Flexible Manufacturing

Achieving flexible scheduling manually can be time-consuming, especially when job priorities, specifications and lead times shift regularly. The E-Max ERP Scheduler is designed to simplify this, helping manufacturers respond quickly while maintaining strong control over capacity and delivery commitments.

Key features include:

- Clear visibility of machine and labour capacity

- Instant adjustments as priorities change

- Real-time updates driven by operator feedback

- Visual dashboards showing bottlenecks, overloads and opportunities

- Scenario planning to model the best scheduling decisions

To see how easy it is to move operations in the E-Max ERP Scheduler, watch our short explainer video: Drag & Drop Operations in E-Max ERP Scheduler

Ready to Improve Your Scheduling Performance?

If you want to operate with more agility, improve on-time delivery and reduce the stress of constant rescheduling, we can help.

Book a demo of E-Max ERP today, Give us a call or drop us a message to see how flexible scheduling and real-time production visibility can transform the way your shop floor operates.