5 Benefits of ERP for Metal Fabricators

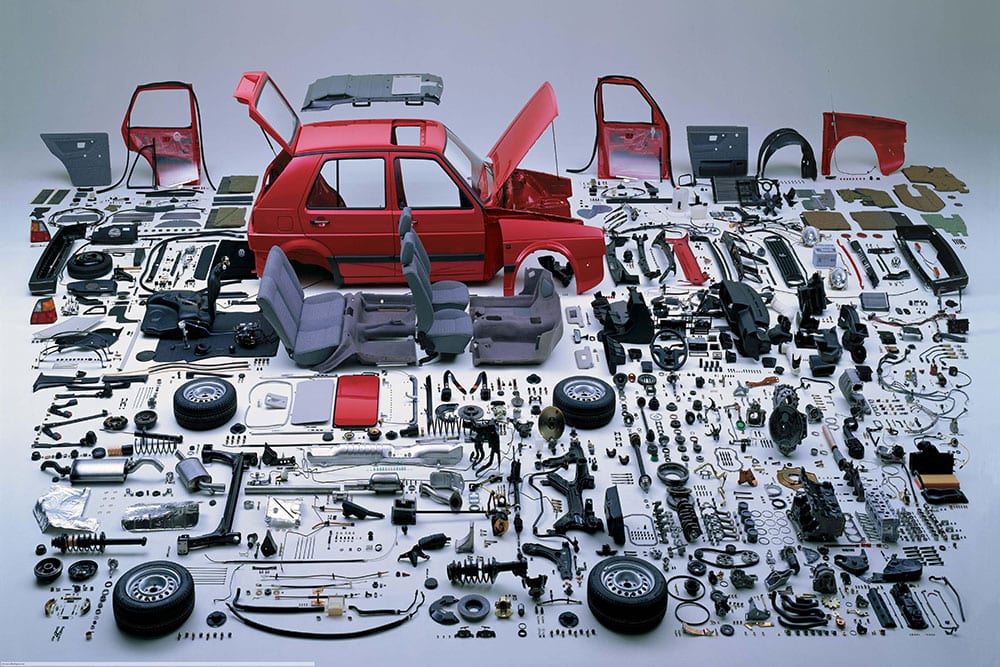

Metal is one of the most common materials that we encounter in our home and working environments. From tools and machinery, to desks and chairs, to kitchen appliances and utensils, metal is used mostly everywhere, in some shape or form, and our lives would be a lot less comfortable without it. So we really should thank the metal fabricators who start the process of turning raw metals into parts that are then assembled into the finished products we use, be it a simple pair of scissors or the nose cone of an aircraft.

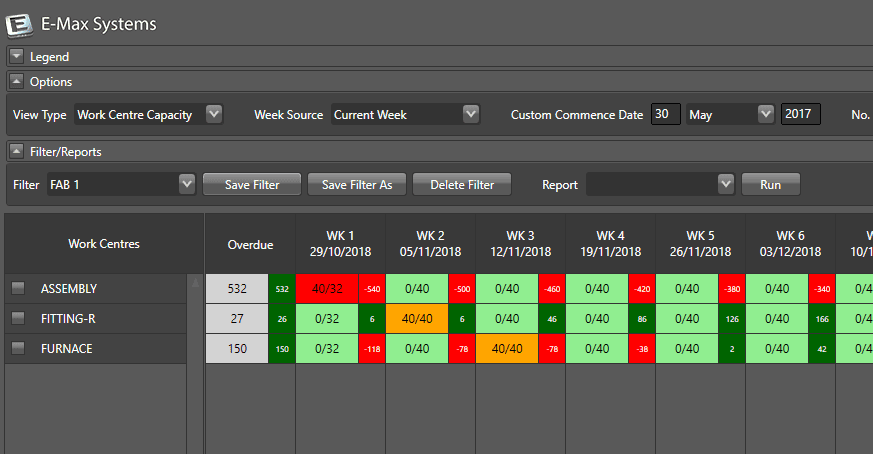

With multiple processes, including bending, punching, folding, laser cutting, welding and machining, involved in producing these initial parts, metal fabricators need to be incredibly organised to run their businesses effectively. Unfortunately, this is easier said than done. Managing processes, costs and materials is a challenge. Overall, an ERP system will offer businesses the structure they need and increase operational efficiency. But what other benefits does ERP offer metal fabricators? Let’s take a look:

5 Benefits of ERP for Metal Fabricators

Comprehensive BOM

Metal fabricators frequently need to manage large bills of materials. These could be different on each occasion but often there is some common elements within projects, such as variations in sizing of similar parts. Being able to copy existing BOMs to a new Bill of Materials, and then adapt as necessary, is a huge time saver and reduces the errors that arise from manual data entry. BOMs can also be imported from design software.

Having multi-level bill of materials functionality is also a real plus point. Even simpler projects may require sub-assemblies and being able to incorporate these into the one BOM makes it easier to see what materials are required, operations to be performed and costings across the whole project.

BOM Control is also a valuable feature to have in an ERP system as it records any changes made to the BOM and stores each version. This enables companies to review the original BOM and see changes that occurred throughout a project and identify whether changes incurred additional costs, etc. This is useful for future reference but also to determine final profitability on jobs.

Batch Traceability

Batch traceability is another benefit of ERP for metal fabricators. Whilst serial number traceability (also available in E-Max ERP) is useful to other manufacturers, batch traceability is of critical importance to metal fabricators who work in regulated industries, such as Aerospace, Oil and Gas or Defence. Being able to trace materials from supplier through each step of the process and to the customer is a must-have feature of ERP.

Inventory Control

Metal has a distinct advantage over other raw materials in that it does not go off or become obsolete, in the way foods or electronics do. However, that means that it can be stored indefinitely, taking up space in a warehouse and tying up cash that could be used elsewhere. Having an ERP system to manage inventory can stop this from occurring by accurately recording what material is in stock, what has been used and its location in the warehouse. The system will take this information into account when producing POs for required material so that existing stock is utilised first and excess stock is not ordered.

Some ERP systems, like E-Max ERP, can take into account offcuts and scrap, particularly important in metal fabrication as these can often be utilised in other jobs. By maximising materials, companies can reduce waste and save money on inventory.

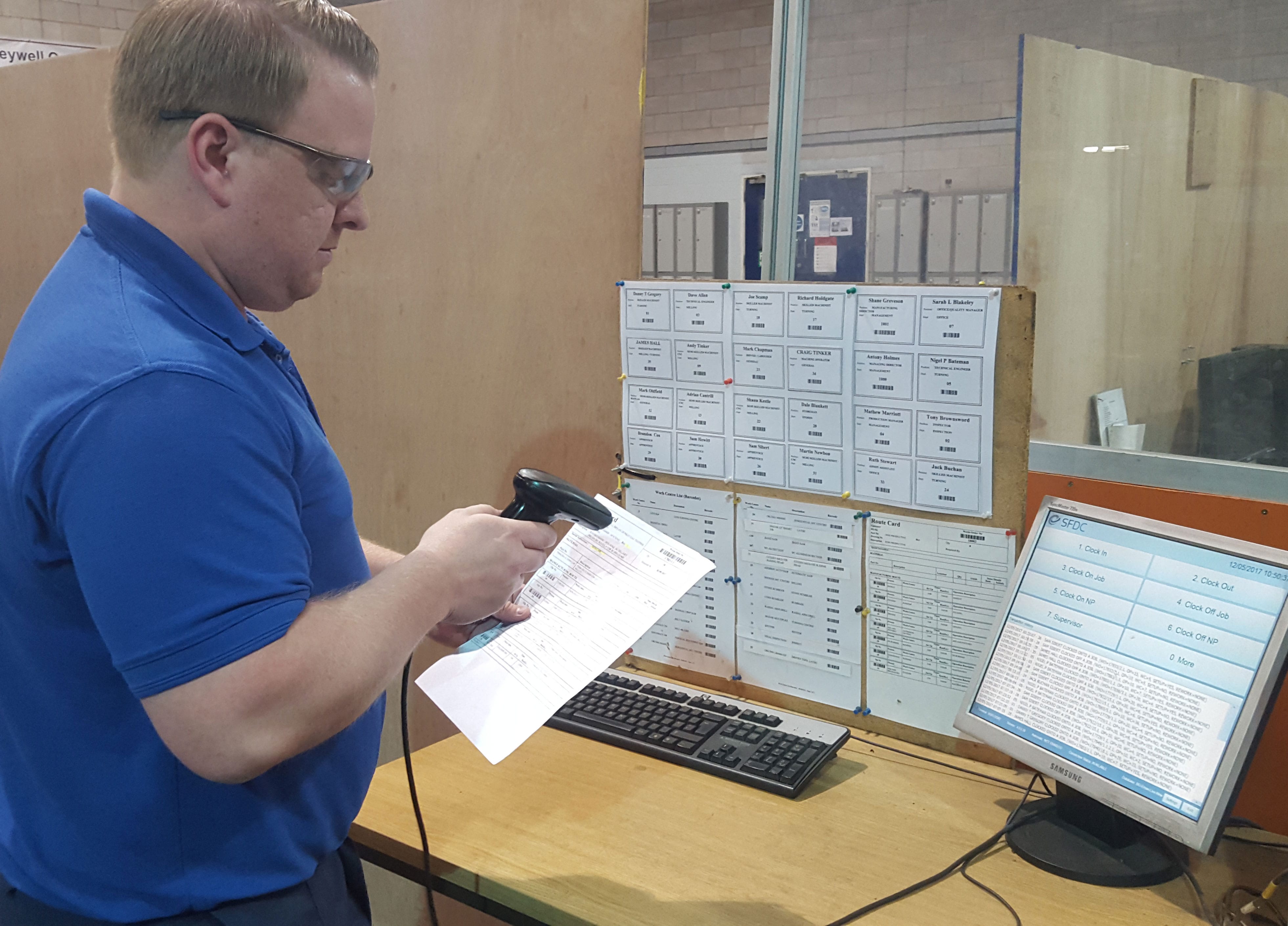

Another benefit ERP systems offer fabricators is providing transparency of stock locations. Once a PO is receipted, labels can be added to raw material and locations noted on the system. Finished stock can also be barcoded once the works order is receipted so that it is clear what each item is. This ensures that a company knows exactly what they have in stock and where it is.

Drawings Control

In complex jobs, metal fabricators may be provided with several drawing revisions during the term of the project. This can also be the case for an item manufactured regularly over time, which is gradually enhanced. In either situation, it is vital that everyone is working to the most current drawing. A good ERP system will include a drawing register that maintains and organises all drawings, revisions and approvals, keeping the most recent version in play and archiving all previous ones. Dates and revision numbers are recorded and changes in each version are easy to see. With this system, traceability and parts management is improved as it is easy to identify when a part was made and to what version number.

Calculate Hours on Job

The amount of time spent on a job can be the difference between a profitable and unprofitable job. It is therefore important to be able to accurately calculate how long your employees have spent on a project. Using a shop floor data collection system integrated with ERP software allows easy calculation of time spent and the cost. Specific hourly rates can be applied to each employee and down time can also be recorded to get a true picture of costs.

ERP enables fabrication companies the opportunity to increase their efficiency and gain a competitive advantage over other businesses in their sector.

To find out more about the benefits of ERP for metal fabricators, speak to our team of experienced consultants or take a look at some other areas of our website. If you’d like to see some of the features highlighted above in action, we can schedule a short demonstration of E-Max ERP at a time convenient to you.