Shop Floor Data Collection (SFDC) – Get the real time view of your shop floor

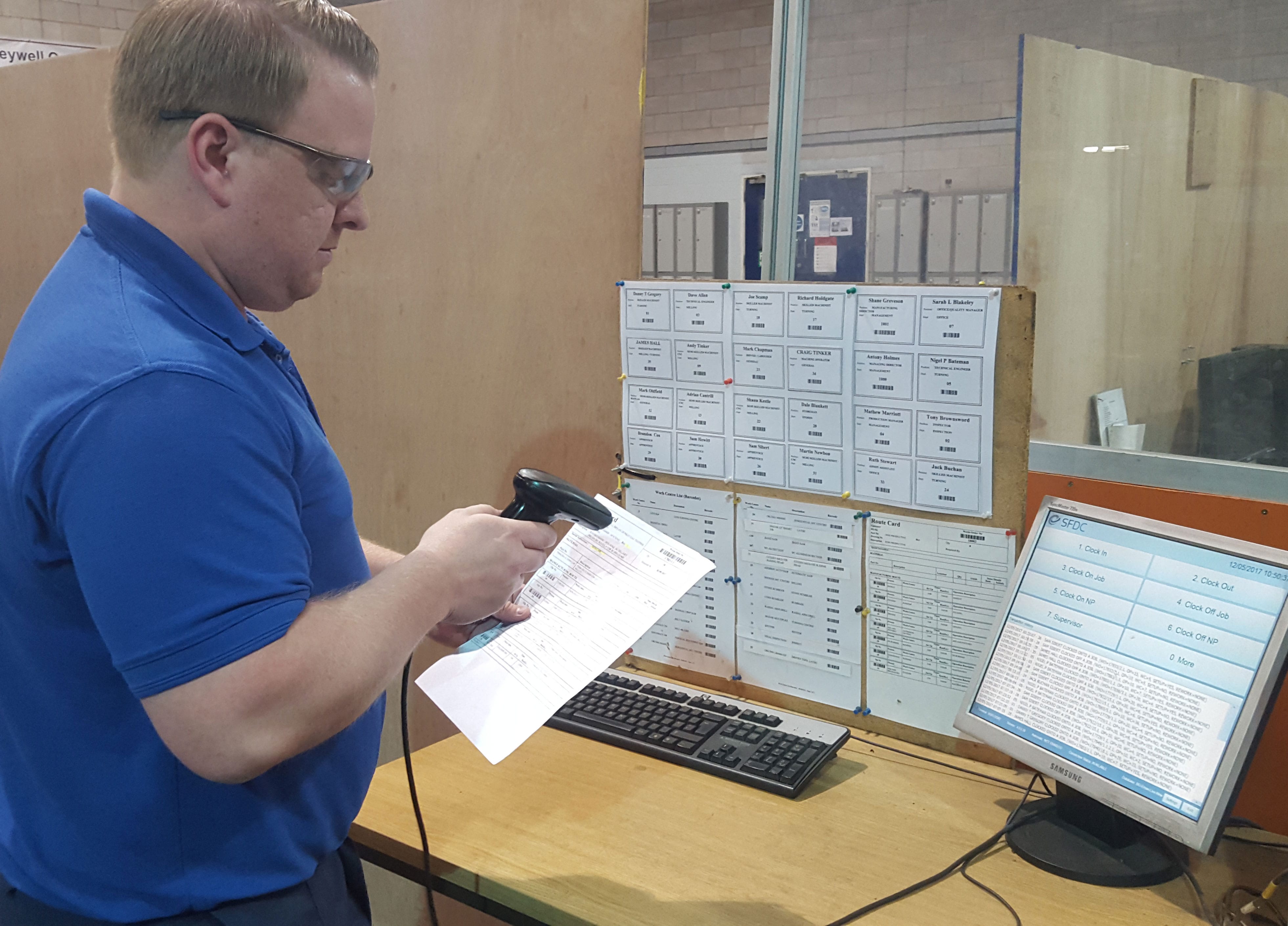

Shop Floor Data Collection (or SFDC) is a simple, low cost system designed to capture information about activity and operations on the shop floor. Mainly used in conjunction with barcode scanners or tablets to enable more efficient and accurate data capture, a Shop Floor Data Collection system replaces traditional paper-based recording methods. Whilst SFDC systems can be used in isolation to record specific data, it is when they are integrated with a company-wide system such as an ERP system that the data collected provides much richer information.

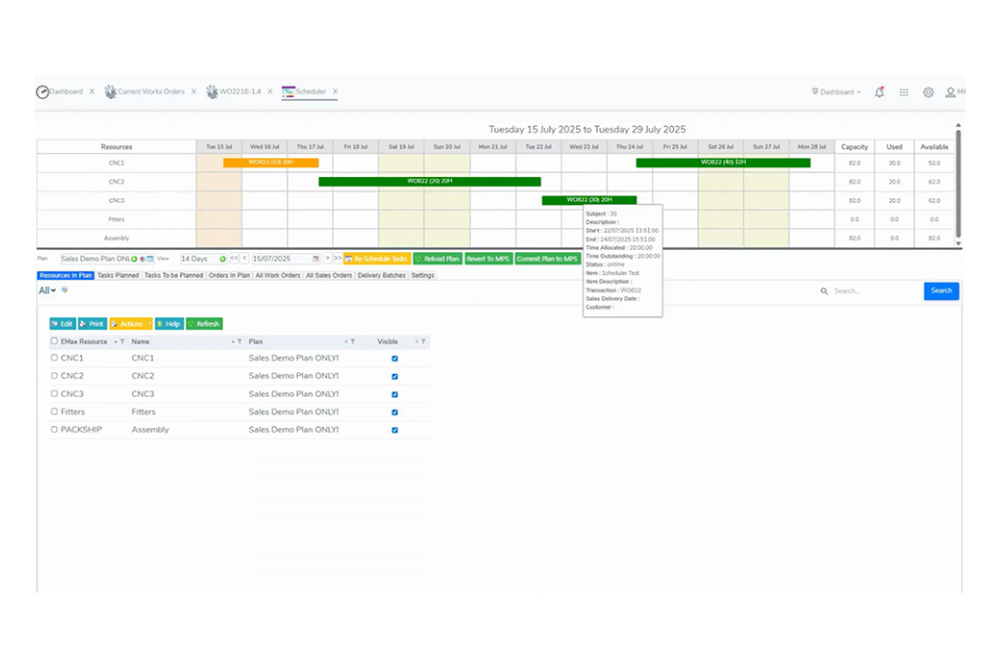

Depending on the scale of their production floor, manufacturers can opt for one or multiple terminals/screens to collect the required data. In larger fast-moving manufacturing environments, individual machines or work centres may have their own terminal to maximise reporting speed and efficiency.

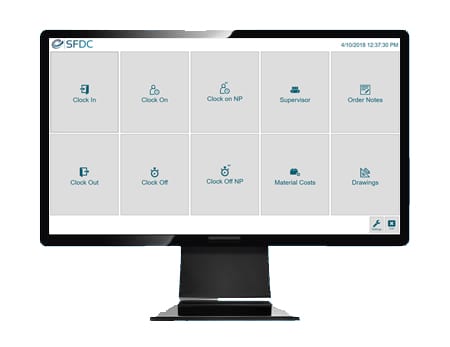

E-Max’s SFDC collects detailed information on two key areas: Job/Time Bookings and Employee Time & Attendance.

Job/Time Bookings

E-Max’s Shop Floor Data Collection allows you to easily allocate costs to jobs as they progress on the shop floor. Machine operators can record their time spent on each specific task or operation quickly and effortlessly with the barcode scanner or tablet. This data flows into the ERP system for management to review and provides a range of benefits:

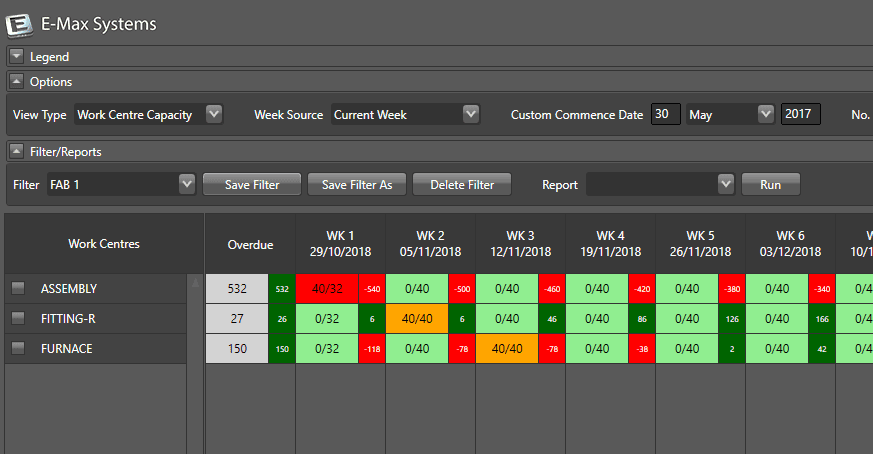

Get real time information on the progress of each job – without doubt, some jobs just take longer than expected and subsequently exceed planned costs. Getting real time information, i.e. that you are underproducing against anticipated daily quantities, allows you to make timely decisions and take remedial action, be it overtime, utilising additional work centres or managing your customer’s expectation.

Access data that previously was unobtainable – shop floor machinery or work centres are expensive investments. Do you know how efficiently these machines are performing? Do you want to calculate capacity utilisation, manpower utilisation or machine utilisation in real-time? With an SFDC system like E-Max’s, it is easy to calculate utilisation of resources and how much it is costing to run a machine over a specified period and ensure that when charging this for every job, this cost and associated additional costs (i.e. finance costs on a machine) are covered.

It’s essential to improve your delivery on time performance – having real time data on your shop floor’s performance is the only way you’ll know for sure whether you will reach target cycle times and scheduled completion dates.

Record your non-productive time – with E-Max’s Shop Floor Data Collection system, you can easily record why a machine is not operating, whether through lack of work, calibration required,. By analysing this data (which is easily viewed through E-Max ERP) trends such as increasing maintenance requirements can be detected and acted upon.

Easily control what people are doing on the work floor – i.e. should the production manager or shop floor supervisor place a job or operation on hold, i.e. due to a drawing change, quality issues, financial reasons, etc, the employee is no longer able to clock on to a job, preventing further work being carried out in error.

Know your employees’ actual productive time – a Shop Floor Data Collection system can record the amount of time each employee is on a machine and where their time is spent throughout the work day/week. Unallocated time can then be reviewed to ensure that employees are as productive as possible.

Employee Time & Attendance

With a Shop Floor Data Collection system like E-Max’s, you can automate the capture of your employees’ working hours. Using a simple barcode scanner, employees can clock in and out at the start of shifts as well as clocking on and off to specific machines and work centres. Each of these ‘transactions’ is automatically captured within E-Max ERP, meaning manufacturers can save time, money and errors by avoiding manual data entry. Other advantages include:

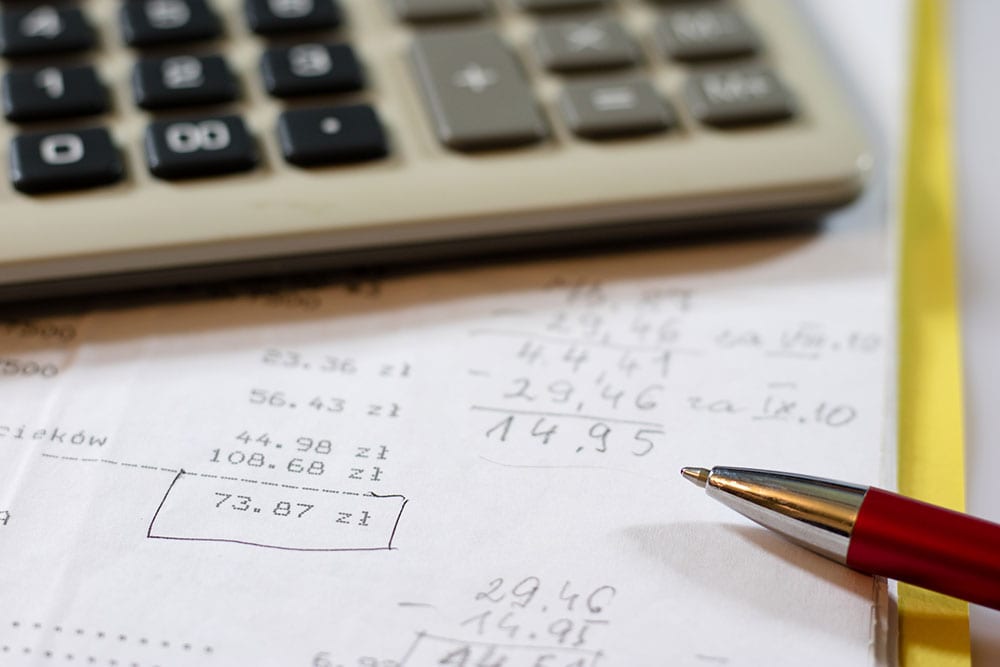

– Easy calculation of employee salaries, with reports of exact hours worked provided to Payroll

– Shift loading is also included, with E-Max’s SFDC allowing you to specify at what times specific hourly rates, i.e. time, time and a half, double time, etc are paid at. The system can also be configured to calculate when hourly rates kick in, e.g. after 35 hours or more are worked.

– Build in your company specific shift rules or tolerances, such as any late times per week.

– Provides an employee list in the event of a fire or evacuation – although it’s not something we like to dwell on, some manufacturing environments have a higher potential risk of fire and other unexpected emergencies due to the materials or equipment being used. Having a real time list of employees who are in the building at the time of the alarm or emergency is a benefit to both employers and emergency services.

– Full transactional history of all hours worked is stored, avoiding disputes over time worked.

5 key reasons Shop Floor Data Collection should be integrated into an ERP system

1. Using SFDC with an ERP system provides a much bigger picture across production, inventory and finance.

2. No integration issues – data is easily and instantly shared and transferred.

3. Replace difficult to analyse spreadsheets with informative reports highlighting trends.

4. Stay ahead of the game with the real time view of your shop floor (no time lags).

5. Become a paperless shop floor, with machine operators able to access key information via the SFDC screens, such as drawings, instructions or comments.

To find out more about E-Max’s Shop Floor Data Collection and how we can help you increase efficiency across your business, take a look at our website, contact us on 0141 644 4424 or drop us an email. You can also book a free demo with us to see our manufacturing ERP system in action.

In November’s blog, we’ll be reviewing what you should look for in a Shop Floor Data Collection system – to make sure you don’t miss out, register to receive our monthly update on the latest industry and ERP trends.