E-Max ERP Review an Engineers perspective of our software

We asked our new ERP Implementation Consultant, Mike Colman, to give us a no holds barred review of E-Max ERP from an engineer’s perspective. As a mechanical engineer with over 15 years’ experience in engineering operations, ranging from CNC machinist through to production manager, Mike is well qualified to put our software through its paces. Being a new member of our team, he was always likely to give our ERP software a positive review, but we found his feedback on his top 5 features very interesting and not what we had expected! Here’s his E-Max ERP review.

“So here I am, a month already at E-Max Systems, already finding it to be an encouraging and enjoyable journey. My experience of working within the engineering sector has been very useful as I explore E-Max ERP in depth. It’s easy to see how the functionality within E-Max’s software will make a massive difference to the smooth running of any engineering or manufacturing business.

My previous experiences with ERP systems have been to learn on the job and pick up techniques and routines to make both myself and the company more efficient. I’ve always tried to harness the full potential of a system but have frequently been left looking for functionality that I felt should be built into the system but never was. That was one of the big draws that convinced me to join E-Max – product features that I had looked for for years but never found come as standard within E-Max ERP.

I’ve been challenged by the team to review E-Max ERP as an engineer and identify my 5 favourite areas of the system. It wasn’t easy keeping it to 5 but I’ve done my best. Hope you find this useful.

- Filters & Searches – a very flexible and accessible way to find what you are looking for in a list. Just create a filter or a search and it will only display the relevant information you are looking to find. This is a simple and effective way to save time as only the information relating to the search you are working on is shown.

- Simplicity of the system – all the screens have a similar look and feel. This consistency means it’s much easier to learn and navigate around the system – once you’ve learnt one area, the same operating principles apply throughout.

- Support at every level – this is a massive help and what I think separates E-Max from the competition. There is extensive support at all stages, from an initial scoping session to determine how a new customer operates and identify the improvements they want make, through to the implementation stage which includes intensive training and system walk throughs to ensure the customer is ready for their ‘go live’. Further support is available once they go live, with a new customer portal and knowledge base integrated into the software. The Support team captures feedback on the system and feeds it into the Development team so that the software is constantly being enhanced.

- Export to excel – I’ve seen many engineering companies use excel spreadsheets for anything as small as a process or table of information right through to literally running the whole company database from one! So it was brilliant to discover this feature as it is a really effective way of gathering information within the system and exporting it out into excel so it is manageable in a way the company finds effective and can use. E-Max offers a range of reports for data so we don’t generally encourage the use of spreadsheets but some companies see these as an easy and efficient way of analysing data. In a previous role, we used to provide weekly updates to customers through excel and having this simple and effective feature would have made our lives so much easier.

- Dashboard – Saved the best until last! This is the game-changer, the wow factor, the main event of the system! I can’t say enough good things about it! I call this the ‘birds eye view’ of the whole system. This is what every MD wants to see – every aspect of their business is on one screen and at the power of their fingertips. Every section of the company can be featured on the dashboard. The interface is fully customisable so that you can set it up to include the KPIs that are most relevant to you. Every user has a dashboard and can access whatever data they need (access rights permitting). The dashboard shows where a company is, what the workload is, highlights any problems, bottlenecks and opportunities for improvement – all the information that management can use to build on going forward.

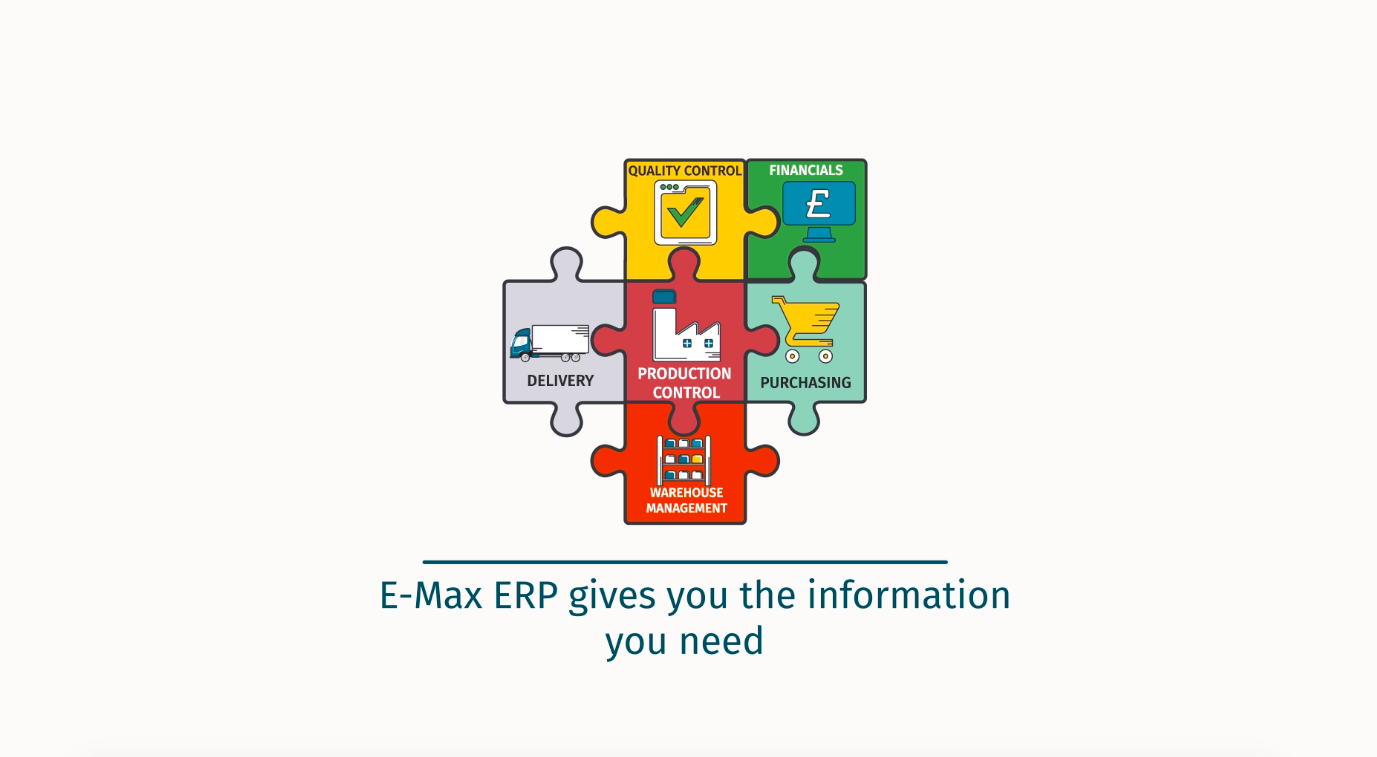

These are the main 5 aspects of E-Max that have made me sit up and take notice. Other features I really like is the way an order is carried right through the different stages i.e. quotes, sales, purchases, stores, production and despatching. The additional features like the scheduler & SFDC (shop floor data capture) means that E-Max ERP really is the complete package. I can’t wait to start implementing it with our new customers – it’s going to save them so much time and effort.”

If you are interested in finding out more about what E-Max ERP can do for your manufacturing or engineering business, then call our team on 0808 109 2035 or message us today. We’d also be delighted to show you how E-Max ERP can work for your company with a free no obligation demo.