What is an ERP system and why does it matter in manufacturing?

Although ERP (Enterprise Resource Planning) has grown steadily over the last two or three decades, we continue to meet companies and individuals who remain unsure of the concept of ERP and what it can do for them. In this article we’re going back to basics and defining exactly what is an ERP system and the benefits it offers to manufacturers.

What is ERP?

Investopedia defines ERP as

“A process by which a company (often a manufacturer) manages and integrates the important parts of its business. An ERP management information system integrates areas such as planning, purchasing, inventory, sales, marketing, finance and human resources.”

Simply put, ERP is the bringing together of the key functions and activities that help a company manage its day to day operations. Usually software based, an ERP system connects business processes and collects and organises information across different departments. Back office functions are integrated into one system, providing a much better flow of information within a company and enabling improved data-based decision making. In addition, ERP systems can also standardise and automate various processes throughout an organisation, so helping to increase operational efficiency.

A brief history of ERP

The origins of ERP can be tracked back to the early 20th century. In 1913, engineer Ford Whitman Harris developed what became known as the Economic Order Quantity (EOQ), a paper-based manufacturing system for production scheduling. For decades, EOQ was the standard for manufacturing.

Toolmaker Black and Decker changed the game in 1964 by becoming the first company to adopt a material requirement planning (MRP) solution that combined EOQ concepts with a mainframe computer.

MRP remained the manufacturing standard until manufacturing resource planning (MRP II) was developed in 1983. MRP II featured modules including purchasing, bill of materials, scheduling, and contract management. For the first time, different manufacturing tasks were integrated into a common system. MRP II also provided a compelling vision of how organizations could leverage software to share and integrate data and boost operational efficiency with better production planning, reduced inventory, and less waste or scrap.

Subsequently, as computer technology evolved through the 1970s and 1980s, concepts similar to MRP II were developed to handle business activities beyond manufacturing, incorporating finance, customer relationship management, and human resources data. Gartner, the world’s leading research and advisory company, created the term Enterprise Resource Planning to describe this evolution and ERP was born.

ERP software evolved rapidly in the 1990s as many large corporate organisations, faced with multiple legacy systems and the threat of Y2K, opted to implement ERP systems as a cost-effective solution to these issues. Today ERP systems are no longer the prerogative of large organisations and are critical to the smooth running of thousands of businesses of all sizes and in all industries. To these companies, ERP is as indispensable as the electricity that keeps the lights on.

Characteristics of an ERP system

There are a few key attributes that an ERP system should have:

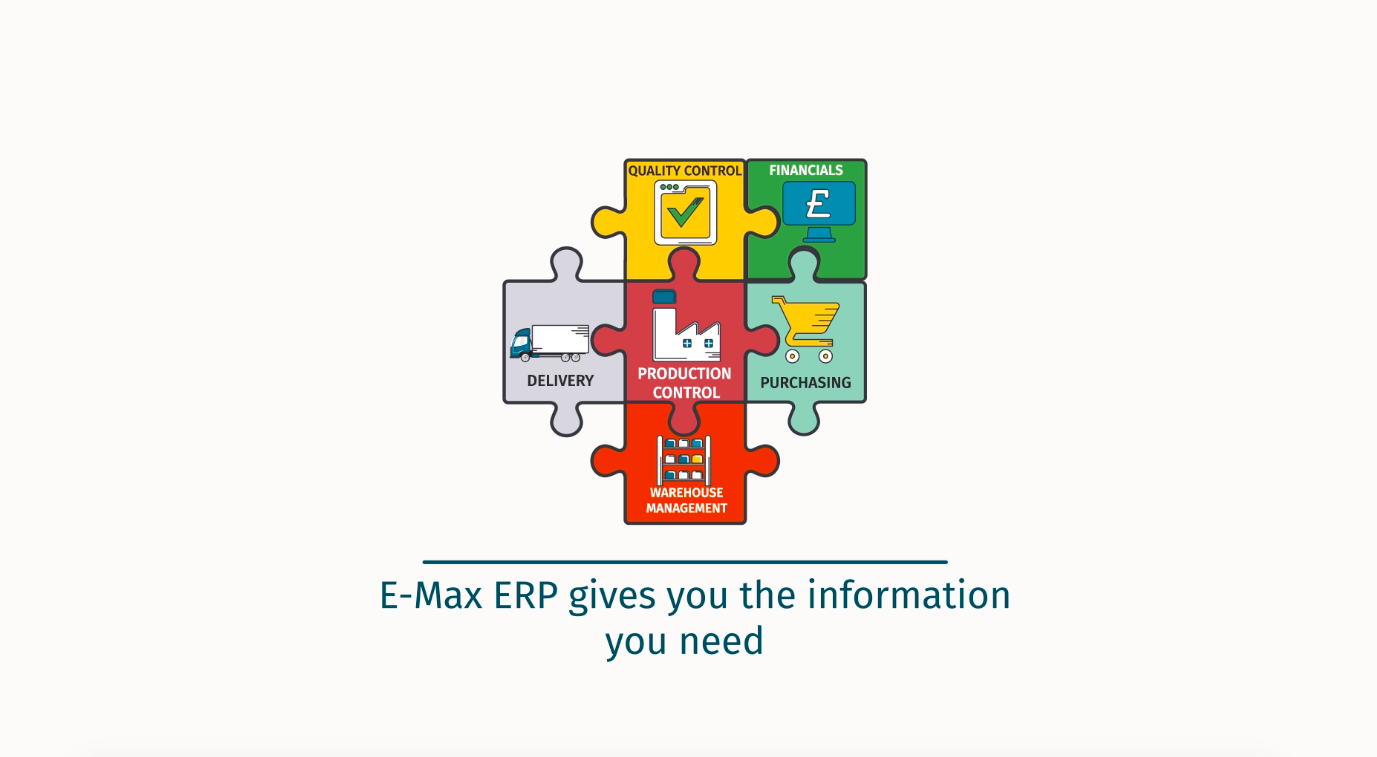

Company wide integration – business processes should be integrated across the company. For example, our ERP software, E-Max ERP, provides enquiry to final accounts integration and automation. Once an enquiry is logged and a new order received from a customer, E-Max ERP will raise a sales order, automatically check stock levels, initiate any required purchase orders, create a requirement for a works order and job card to fulfil the demand and push the job into the scheduler. When the order is shipped, an invoice can be sent directly from the system via email.

A single database – one underlying database will collect and organise all of a company’s data to facilitate decision making. Data therefore only needs to be entered once and can be used by every department.

Consistent look and feel across all modules – by standardising the look and feel of the user interface, training costs and time are reduced. A consistent look generally appears to be more professional and gives users confidence when using different elements of the system.

Flexible and open design – as business requirements are constantly evolving, an ERP system should be flexible in design to allow specific modules to be activated or deactivated as required without affecting the other modules. Integration with company- or industry-specific applications should also be available. Scalability is also important to ensure an ERP system can continue to benefit a growing organisation.

Operates in real time (or near real time) – to allow an organisation to act quickly and respond to issues.

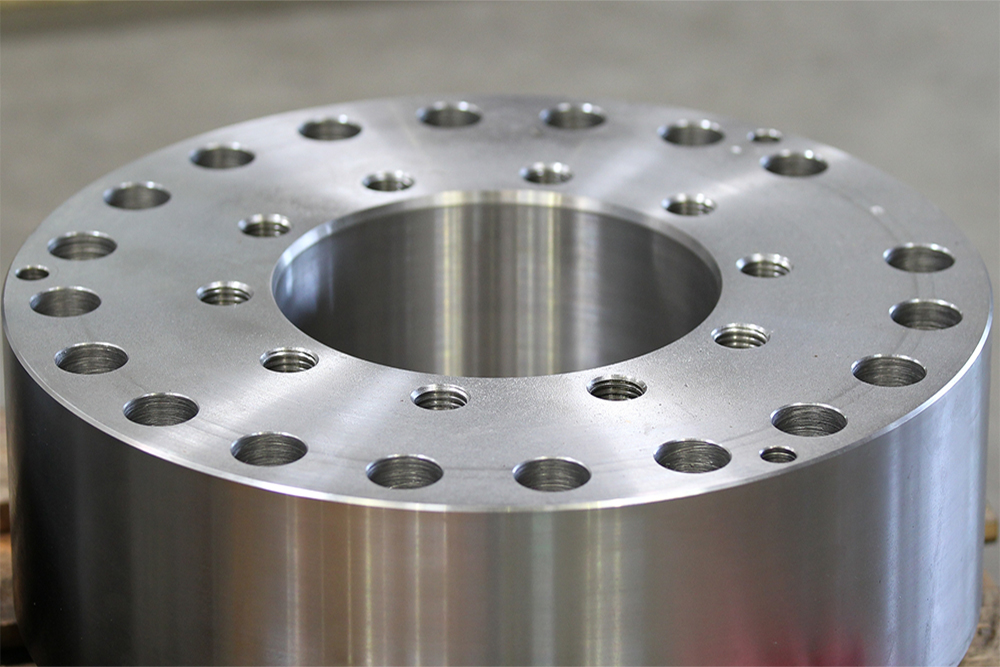

Functions of a manufacturing ERP system

An ERP system should typically offer the following areas of functionality. These are usually separated into modules but work as an entity.

Customer Relationship Management – contact management, opportunities / enquiries, estimation and quotation, customer service, sales and marketing, campaigns, activities and tasks, email integration

Sales Order Processing – order entry, credit checking, price lists, live available stock, shipping and delivery management, sales analysis and reporting, sales invoices

Production Control – MRP, bill of materials, work orders, scheduling, capacity planning, project management, reworks and rejects

Purchasing – purchase orders, purchases required, purchase invoices, supply chain planning, delivery scheduling, request for quotes (RFQ), supplier price lists, supplier management, analysis of supplier performance

Warehouse Management – inventory control, stock location, goods in, picking and packing, goods out, vehicle logistics

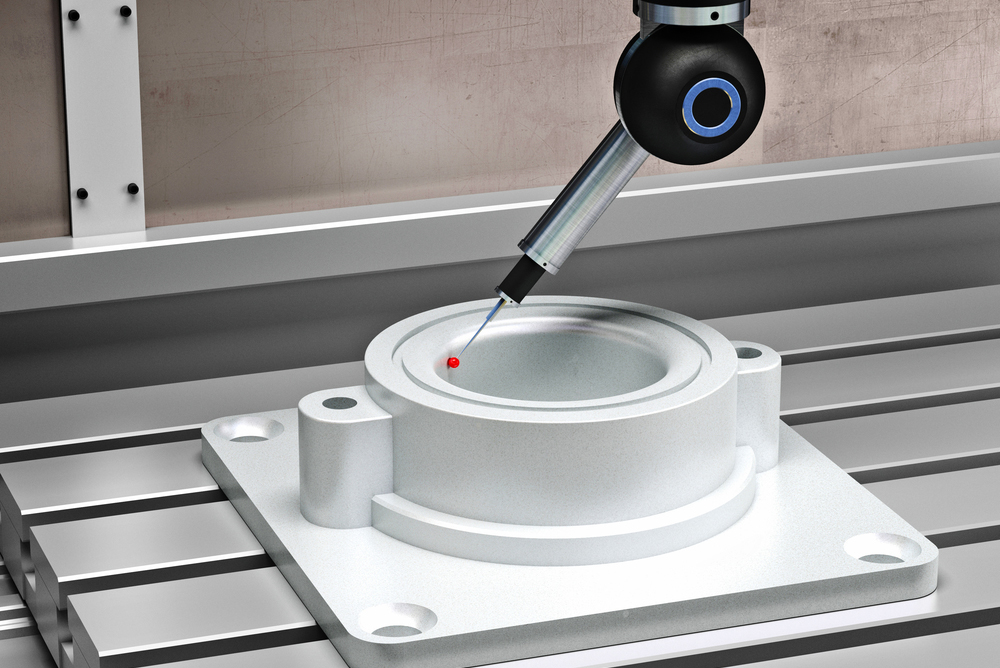

Quality Control – test certificates including certificates of conformity (CofC), tests, specifications, non-conformances, traceability control (batch, serial, location, FIFO, LIFO, etc.)

Finance – general ledger, sales ledger, purchase ledger, accounts receivables, fixed assets and depreciation, bank reconciliation, budgeting, company-wide cost analysis, accounts periods

Human resources – training, leave management, absentee management, discipline, shift management, time and attendance, health and safety incidents

Benefits

ERP systems bring a host of benefits to manufacturers. We’ve listed our top 5 benefits below but the list goes on and on – just ask some of our customers. Here’s the ones we believe have the most impact for manufacturing organisations:

1. ERP systems improve efficiency within a business. As ERP systems tend to be built around perceived best practices for particular industries and sectors companies can take advantage of these to streamline their own processes.

2. Real time information is available to management and departments allowing them to make better decisions, act more quickly and be more agile.

3. The automation of processes enables manufacturers to plan better, deliver more and faster, whilst reducing costs.

4. A single source of data ends duplication and improves data integrity, as well as allowing everyone to work to the same key performance indicators.

5. Makes your data more secure, both internally and externally, and makes compliance with industry standards, such as ISO 9000, much easier to implement and maintain.

Disadvantages

It’s true that there can be some downsides to an ERP system. Initial acquisition cost of a system can be high, particularly if using one of the large ERP vendors where costs can run into 6 or 7 digits in some instances. The good news is, for manufacturing and engineering SMEs, there are plenty of smaller vendors offering a range of ERP functionality, meaning investing in a major corporate system is not necessary.

Implementation can also be a challenging period for a company, requiring time and resource to get it right. A good ERP provider will take the time to work closely with potential customers to understand their needs and offer solutions to make the implementation process as smooth and short as possible.

Integration with existing internal systems may also throw up issues. Whilst an ERP system should be the primary software within a company, there are often occasions where a company may need to use an existing specialist application such CAD software or nesting software, etc. When looking for a new ERP system, businesses should look for flexible systems that offer the option to connect with additional software, for example, E-Max ERP has a number of API links already built for manufacturers and engineers to aid this process.

So, to ERP or not to ERP – that is the question

There are undoubtedly many benefits that ERP systems can offer. Many engineering and manufacturing businesses are now utilising ERP software and enjoying the competitive advantages it provides. Whilst there are some perceived disadvantages in bringing on a new integrated system, these can be managed to minimise their effect and there is no question that, in the long run, ERP systems can significantly improve and grow your company.

For more information on E-Max ERP, call 0141 644 4424 or drop us an email. Alternatively, why not book a free 30 minute demo of our ERP software here?