Why a quality production control (MRP) system is essential to manufacturers

We’ve all heard the old adage that by failing to plan we are planning to fail. But this has never been truer for manufacturers than it is today, with ever rising costs, demanding customers and increasing competition in both local and global markets. It’s not all doom and gloom though – the development of production control or MRP software (our clients regularly interchange these two terms so we will too) means that all sizes of manufacturing companies can efficiently plan around their workforce, equipment and materials to ensure they deliver on time to their customers at the agreed price.

So how will MRP software help improve your manufacturing company’s bottom line?

Taking it back to basics, MRP (or more accurately, MRPII – Manufacturing Resource Planning) is a method for the effective planning of all resources of a manufacturing company. By using an MRP system to plan operations, control inventory and organise logistics, manufacturing and engineering businesses can reduce costs and optimise their processes, making them much more competitive.

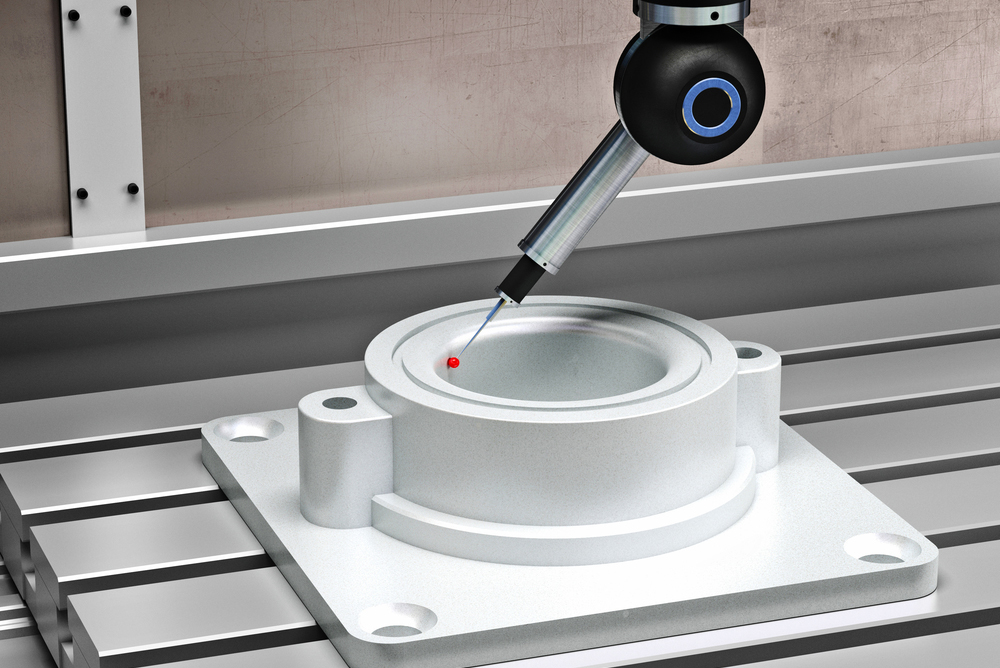

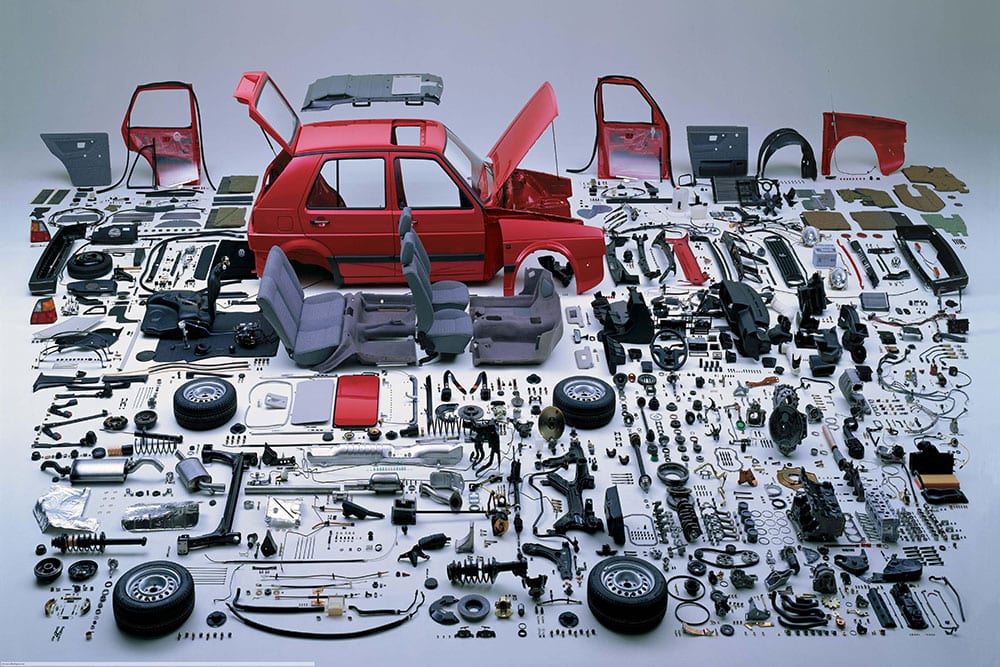

Whilst in theory an MRP system doesn’t need to be computer based, it is hard to envisage such a complex planning system not taking advantage of the speed and reduced processing time MRP software can offer. Consider the amount of time needed to manually create a bill of materials (BOM) for an intricate – or even relatively simple – component and then how long it would take to manually calculate what raw materials need to be purchased (and delivered) to support the production schedule – ouch! And that’s not even factoring in the production of sub-parts!

By producing a set of planned work orders for each job and scheduling these orders to meet the customers’ deadlines, MRP or production control software can hugely reduce the amount of effort and time required for planning the production process. This allows production planners to focus on data analysis rather than data collection. But how else can it benefit a manufacturer?

3 key benefits of MRP software

1. Improve customer service

By bringing all the data together into the MRP system, production schedules can be accurately planned. This allows manufacturers to meet their promised delivery schedules as well as shortening their delivery lead times = increased customer satisfaction.

2. Reduce inventory costs

With MRP you can plan and schedule production operations without buying in excessive inventory – in line with Just In Time manufacturing principles. You know exactly what you need and when you’ll need it so there’s no need to overcommit on the inventory front. This in itself brings huge advantages – you’ll improve your cash flow, remain liquid and can even make your money work harder by diverting it into other areas such as a new production line, machinery, workforce training or better marketing campaigns. And by holding less stock, you’ll save on storage space.

3. Improve operating efficiency

By assigning operating priorities and capacity to load production systems, production processes can be optimised. There’s less downtime of personnel and equipment and as it is clear exactly when a job will be completed, it is easier to organise the logistics of getting them to the end customer.

So to paraphrase the British Army’s 7Ps, by using MRP or production control software to Properly Plan and Prepare resources, we can be sure we Prevent Particularly* Poor Performance. But if we weren’t?

(*we went for the soft option here – you can see the original version here!)

Risks associated with not using a quality MRP system

1. Can’t deliver on time

Not having a production control system in place means that the chances of you not delivering on time increase. Issues such as delayed raw materials, production schedule clashes or a lack of delivery options can all cause an order to run late. With MRP these issues are highlighted instantly, giving you the opportunity to take remedial action.

2. Unhappy customers

Unhappy or dissatisfied customers will look for discounts or move their business to a competitor. Either way, it’s detrimental to your bottom line and unsustainable in the long run.

3. Excessive cash tied up in inventory

Having to use significant funds for inventory often has implications for cash flow. It can also make businesses less agile and unable to quickly respond to changes in demand

Should I implement an MRP system?

Every manufacturer, regardless of the size of their operations, knows that planning and scheduling are vitally important to ensure that they get their products out of the door to their customers on time. Automating the production process with production control software helps ensure this is achieved and creates higher levels of productivity within a company.

Maybe you already have an existing MRP system but aren’t sold on it? MRP (and ERP) has continued to develop, with better functionality and options. Legacy systems that may be 10-15 years old could be complicated and ineffective, as well as costly. Newer MRP systems incorporate best practice to ensure you are at least as efficient as any of your competitors.

But to our minds, the most important factor that a quality MRP system can provide is the ability to grow your customer satisfaction and with it, your business. With an MRP system you have the answers to all the important customer questions like “how much will it cost” and “when can we have it”? Accurate responses to these questions help enhance your reputation as a reliable supplier and keep the customers coming back. We’ve seen our customers achieve great results and growth after implementing E-Max’s production control functionality.

Using an MRP system to plan operations, control inventory and organise logistics, enables manufacturing and engineering businesses to reduce costs and optimise their processes, making them much more competitive. Surely that’s where we all want to be?

At the core of E-Max ERP sits our proven MRP system. To find out more about the impressive functionality it offers, visit our production control page, give us a call on 0808 109 2035 or drop us an email. Of course, if you’d like to schedule a free, no obligation demo of the system in action, you can book here.