Manage Activity to Manage Productivity how ERP software can help

Since the development of MRP (Material Requirements Planning) and MRP 2 (Manufacturing Resource Planning) by Oliver Wight followed by the natural progression towards ERP (Enterprise Resource Planning), the pursuit of effective and efficient management of a manufacturing enterprise has come a long way.

This, coupled with the emergence of modern and widely available technologies, such as Microsoft.NET (utilised within E-Max ERP software), means that the opportunities for business wide efficiency and productivity for the manufacturing industry have never been greater.

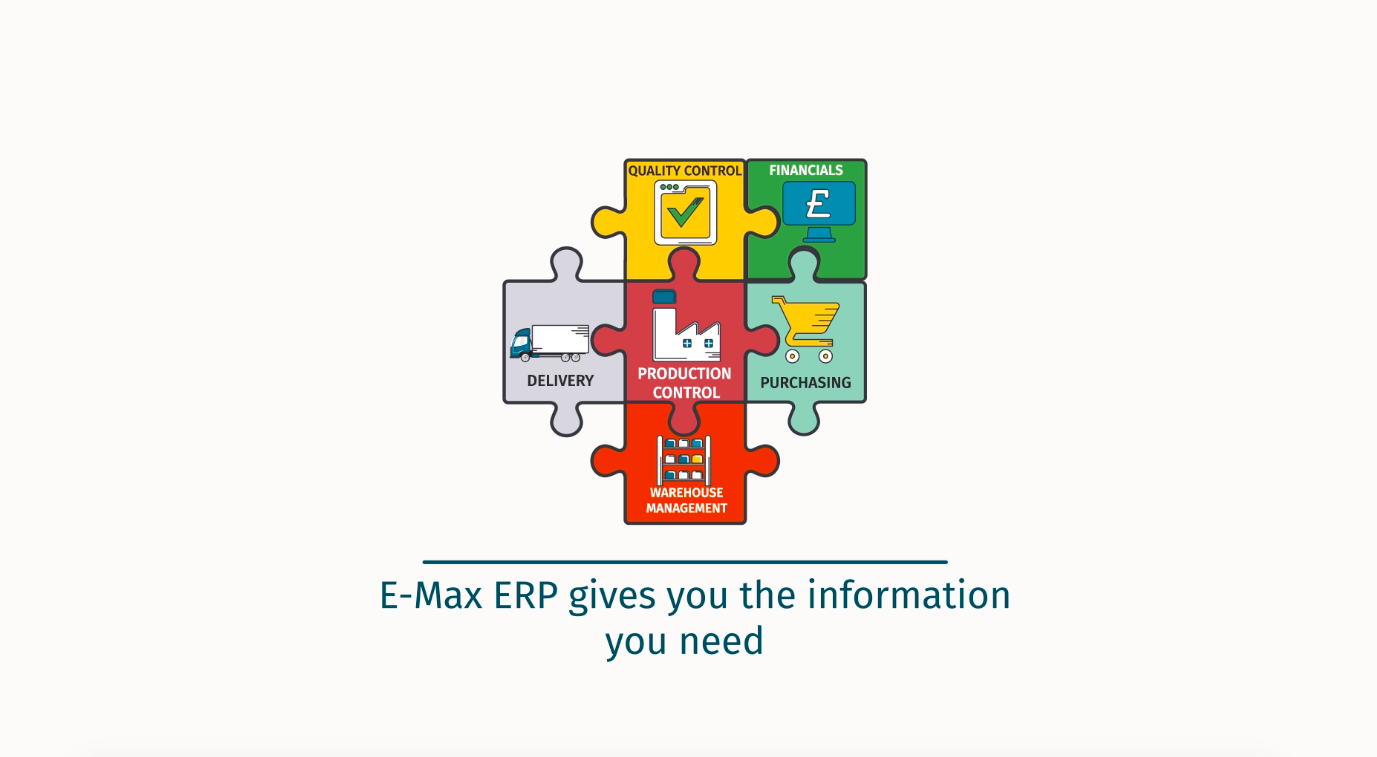

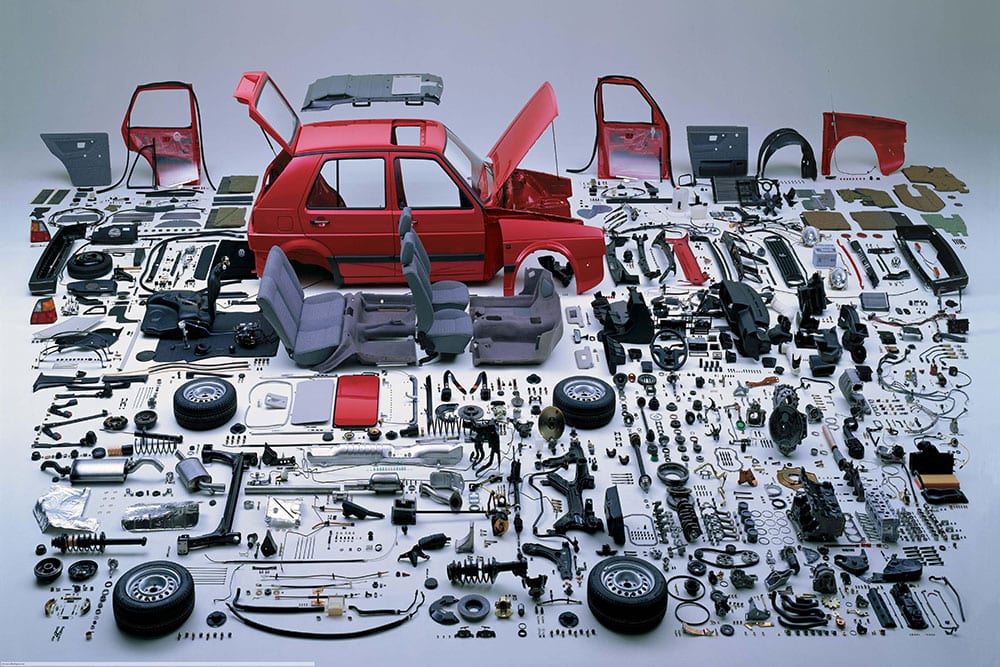

Although fundamentals of MRP/MRP 2 remain the same i.e. what do we need to make, what do we have in stock, how do we make it, when do we need to deliver it to the customer, etc, ERP software has evolved on from this and now encompasses a host of additional business processes and activities that manage and support the manufacturing process.

In a nutshell, these activities take place around:

- Information flow from enquiry to invoice

- Physical flow of materials and products

- Financial flow

The importance of tasks

At E-Max we firmly believe the optimal way to improve your productivity is to to focus on managing every task or activity in the production (and general business) process(es). By ensuring everything is managed – generally by way of an ERP system, activities are completed in the most efficient, timely and productive way possible. So, to paraphrase the old proverb, “look after the tasks and the productivity will look after itself”.

That’s why E-Max ERP has been developed to simplify the management of typical processes in a manufacturing environment. At the centre of our software is the interconnected activities or tasks which form business-wide processes and transactions from enquiry to invoice – all relevant to engineering and manufacturing companies.

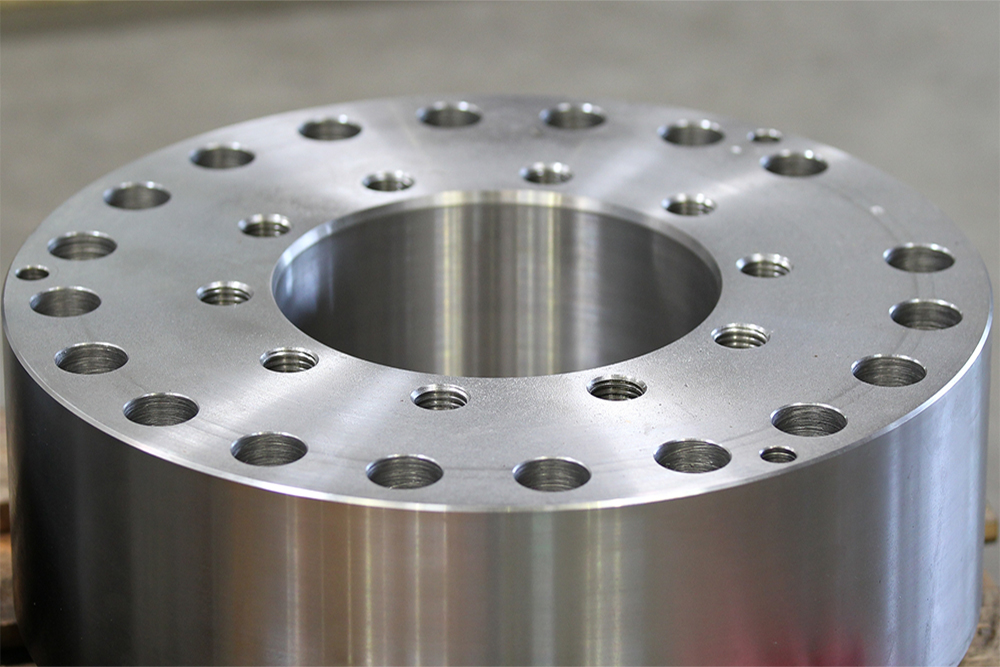

To assist workflows in traditional engineering and manufacturing, when a new enquiry or opportunity is received from a customer, a quotation is generated. This includes an accurate estimation and the details of the product to be manufactured. It can be emailed electronically for approval by the customer, after which a sales order is generated if the order is won, followed by the creation of a new project. Stock levels are monitored and kept accurate and purchase orders can be generated in line with Lean and Just-In Time principles.

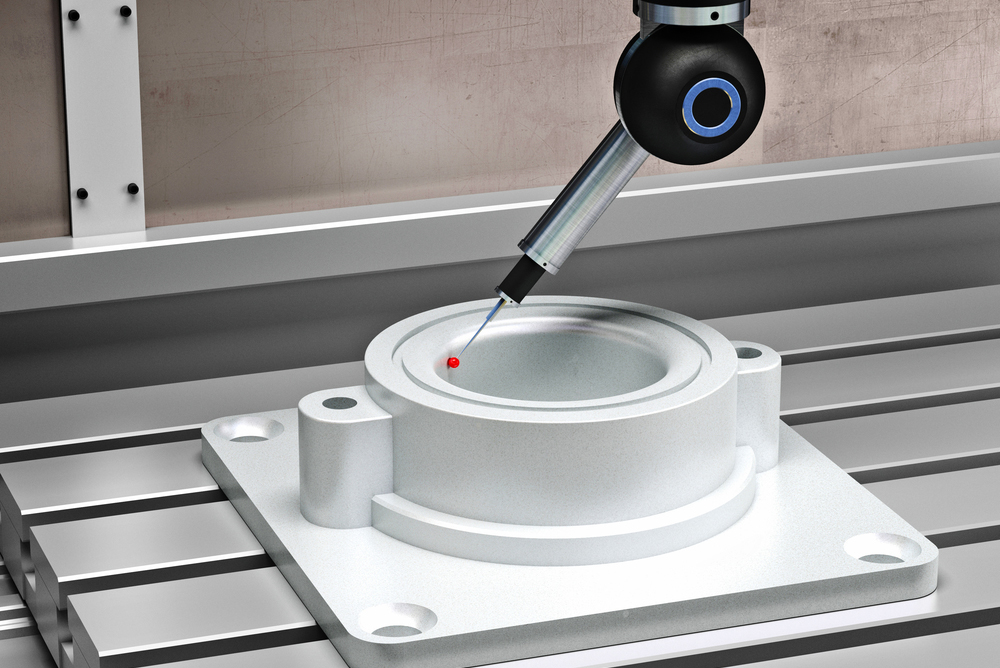

Whether engineer to order, make to order or made to stock, physical activities can start. Route cards can be created with barcodes, pieces of metal are cut, turned, welded, etc. Complicated multi-level bills of materials are processed, assemblies are made. Subcontract operations / activities take place.

Both sales and purchase invoices are generated and monitored to help the employees oversee financial transactions across the whole enterprise.

However, as businesses increasingly communicate electronically, an email from a customer with relevant documents can trigger an enquiry, as can an enquiry via a website. With the rise of social media, an enquiry can even be part of an open discussion on LinkedIn, Twitter, etc. Even with these multiple response routes, all activities can simply be created and followed up accordingly as part of an evolving conversation with relevant follow-up reminders and tasks.

All of the above are the operational activities or tasks that a manufacturing company must undertake to be successful. E-Max ERP software provides the structure to ensure these tasks are recorded and completed in a systematic way.

Achieving productivity

The sharing of information enables other departments and employees to see what is going on in other departments. There is no duplication, requirements cannot be forgotten or overlooked, or incorrectly entered into another standalone system. By having every activity on the system, the organisation benefits from an increased level of accountability.

Real time monitoring of performance and company-wide KPIs is possible by using dynamic reporting and business intelligence tools.

Ultimately, ERP software is a uniform and integrated enterprise that manages and controls activities for everyone within the organisation, helping to achieve the ultimate goal of delivering the customer’s order on time, in full, whilst achieving a high standard of productivity.

For more information on E-Max ERP software, contact us on +44 (0) 141 644 4424, drop us an email or why not book a free demo with us?