E-Max ERP: Why Its Not Just For Traditional Manufacturers

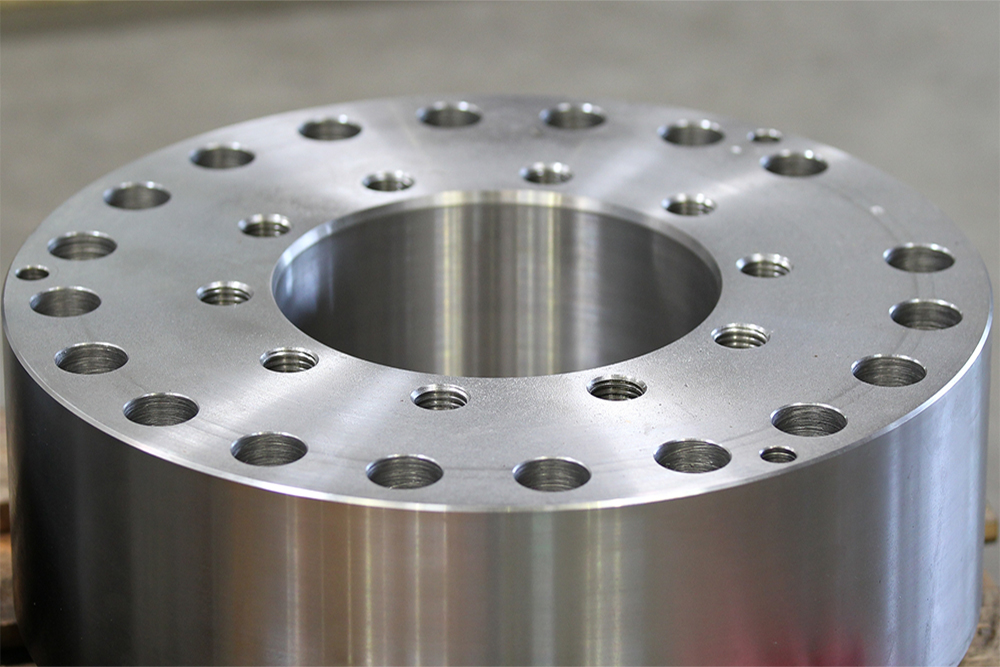

When we first developed E-Max software, our original design was based around the requirements of traditional manufacturers: companies who manufacture parts exclusively for a specific customer. Defined as the make to order (or MTO) sector, this includes companies such as the classical precision engineer or fabricator.

These types of organisations typically don’t do any design work and instead receive the original drawing from their customer along with instructions on how to make the items, information on what tests/checks to make and when in the process.

Other businesses in this sector might design and make a specific item or machine for a customer. By and large, everything is manufactured or purchased for each order, with nothing kept in stock.

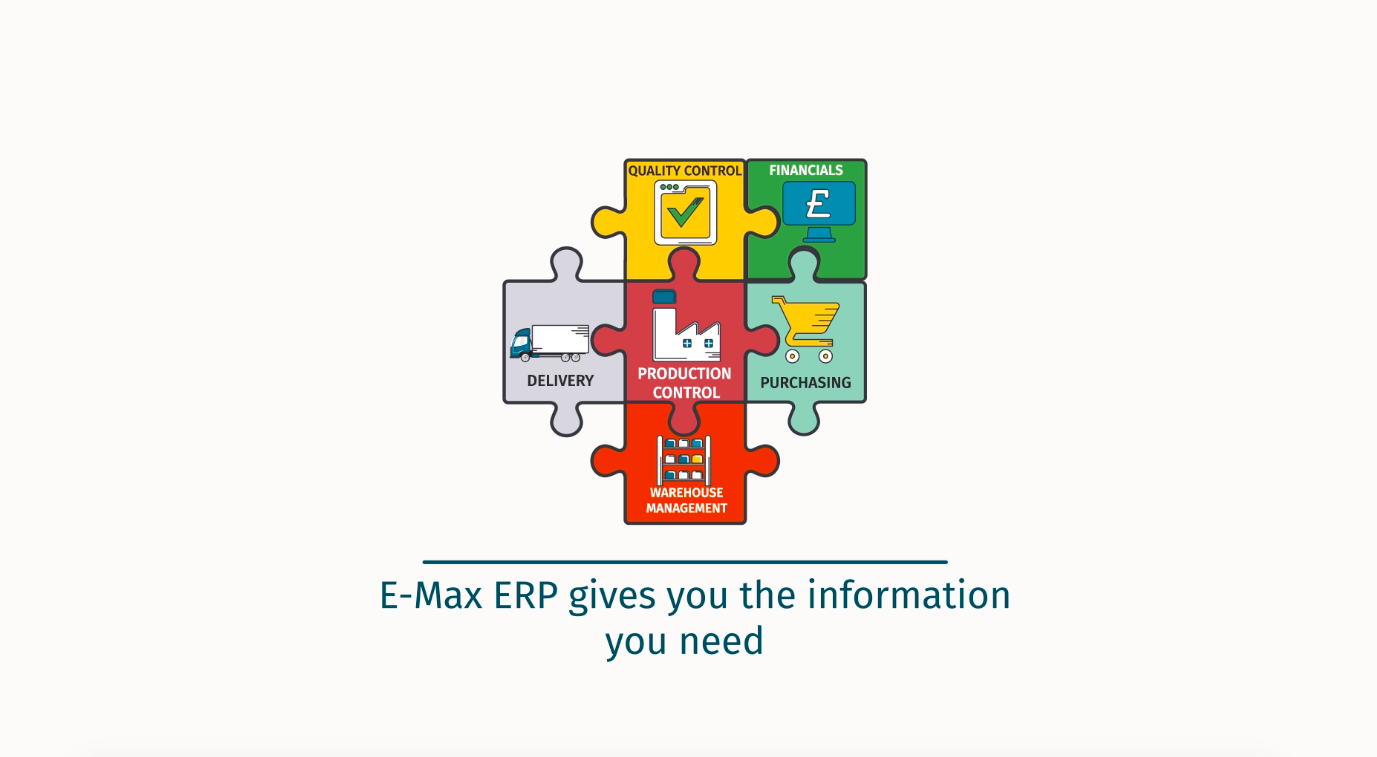

Over time, we developed our ERP software to meet the needs of other businesses within the manufacturing sector. These include companies who build or make to stock (MTS), ie making and stocking both finished items and components. When a customer order is received it is generally fulfilled from stock. As finished items are consumed and the stock falls below re-order point this triggers the requirement to raise new orders. These new orders then consume components which again triggers orders for components.

E-Max ERP is also ideally suited to a variant of the MTS mode: configure to order in which an organisation typically keeps stock of components and assemblies which it then puts together to meet a specific customer order.

Whilst E-Max ERP is a perfect solution for the above traditional manufacturers, the whole manufacturing sector is now much more fragmented than at any time in its history, and organisations who may once have been these traditional manufacturers have sought to expand their service offering. For example, they may do significant amounts of repair work or rent out the items they make. They may also want to service and control warranty claims on the items they manufacture.

E-Max ERP, in addition to handling our original “make to order” market, now also offers powerful configurable solutions in these wider areas. Below are 4 key functions that enable E-Max ERP to make a significant difference to manufacturers who offer or intend to offer a broader service to their customers.

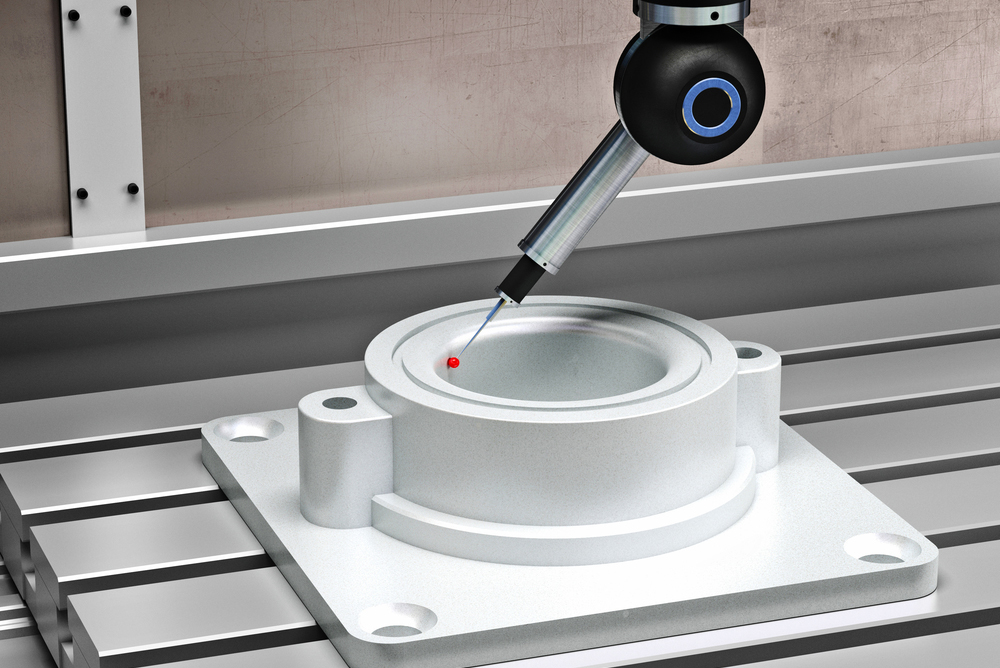

Change Control

E-Max ERP records revision changes with supporting documentation such as Engineering Change Notices. If stock of components exists, the system records the revision of these items.

If parts are in production at one revision and there is an engineering change affecting that item, it is possible to change the revision in production and book in a new revision.

It is also possible to keep a history of revision changes and call up the Bill of Material (BOM) and the route of a previous revision. Previous revision of an item can also be manufactured if required.

The ability to record revision changes can also be important for make to order companies, especially if they make assemblies and not just components for their customer.

Forecasting Stock Requirements

E-Max ERP supports the entry of a sales forecast for finished items or semi-finished assemblies. Via its powerful MRP functionality the bills of material (BOM) for these assemblies are exploded into requirements for basic manufactured and purchased parts. These requirements can then be used to generate purchase orders and works orders to ensure the stock exists when the actual orders materialise.

The system also produces forecast stock balances for each transaction on an item making it easy to see exactly when a part will run out.

Stock Control

If the range of product and components is large, forecasting how many are required might not be possible. In these situations, monitoring stock usage and re-order points is very important. Each item or part therefore is given a re-order level and re-order quantity. When the item falls below the re-order point it is automatically re-ordered.

E-Max ERP can monitor and amend re-order points based on current levels of consumption. Too high a re-order point, if not based on realistic consumption figures, can lead to carrying excess stock. E-Max ERP monitors consumption of every stocked item and, should it ncrease, the re-order point will be recalculated accordingly. Likewise, if usage is decreasing, the re-order point is also be recalculated.

Warranty and Repair– Management and Costs

The system also logs repairs and warranty costs against each serial number of finished product made. Functionality to administer the repair of the items is also incorporated.

If the company employs or uses third party repair engineers then E-Max ERP can help manage the course of the repair. This includes the logging of the original call via the creation of a support case. Also built into E-Max ERP is a knowledge base that the customer can maintain and use to suggest potential solutions to problems.

Via the identification of the serial number and date of manufacture, it is easy to find out if that item is still under warranty. At this point, a service order can be created and allocated to an engineer. Parts required for the repair can be identified and either issued to the engineer or sent to site.

Costs can then be collected along with information on the cause of the fault. In this way, a history of each serial part produced is maintained.

So although our software was originally designed for traditional manufacturers, the functionality we have added now means that a much broader range of businesses in or on the edge of the manufacturing sector can benefit from the power and flexibility of E-Max ERP.

If you’d like to find out more about E-Max ERP and how it can help improve your business, please take a look at our website, contact us on 0808 109 2035 or drop us an email. You can also book a free live demo with us to see what our manufacturing ERP system can do for you.