Cloud ERP for UK Manufacturers – A Complete Guide

Summary:

Cloud ERP delivers ERP software as a secure online service, helping UK SME manufacturers reduce upfront costs, deploy faster, and gain real-time visibility across production, stock, and finance. With automatic updates, strong security, and easy scalability, it supports multi-site teams and reduces IT overheads compared with on-premise ERP. Some of the biggest benefits include tighter control of WIP, improved traceability, and faster, data-driven decision-making.

What is Cloud ERP?

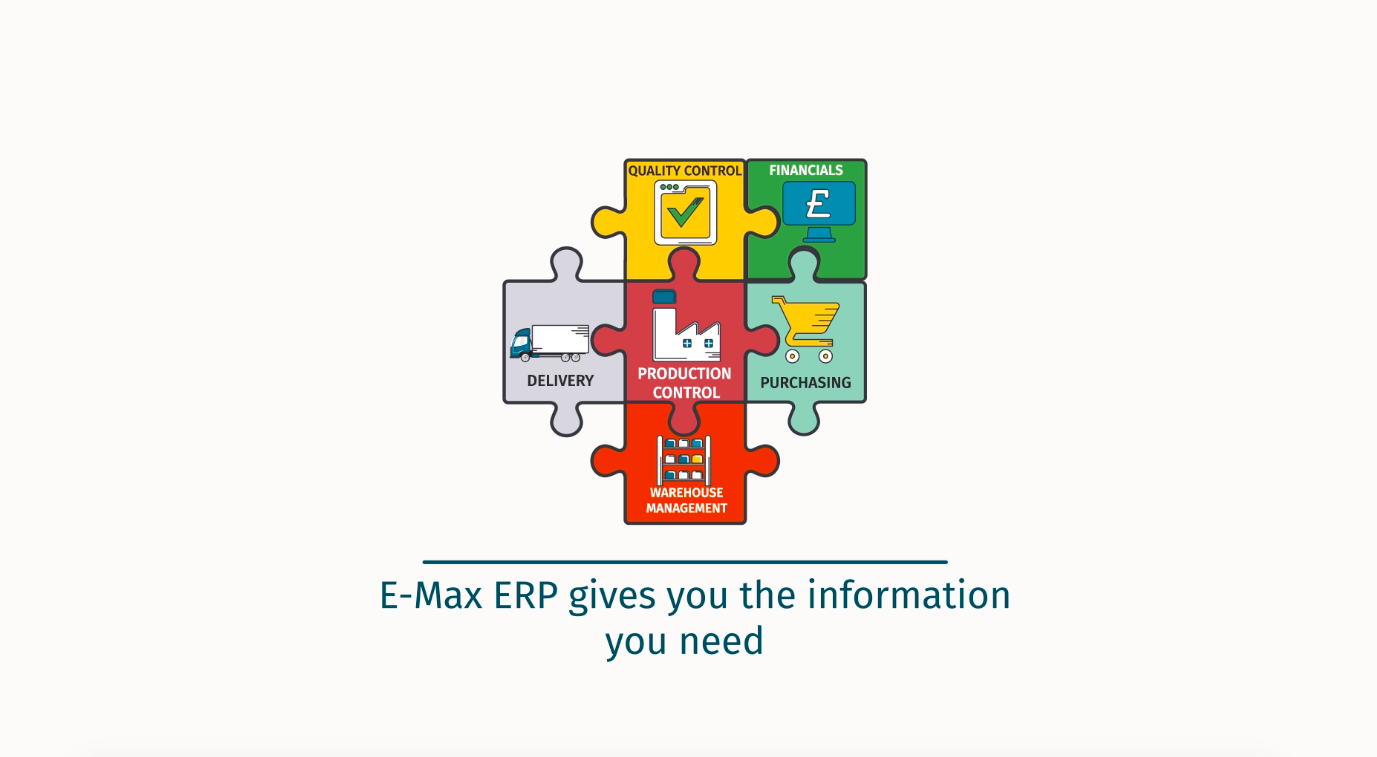

Cloud ERP (Enterprise Resource Planning) is a type of software that helps companies manage their key business processes - from customer relationship management (CRM), through to supply chain management, production, and finance - using cloud-based technology. Unlike traditional on-premise ERP systems, it is hosted by the ERP provider in the cloud and accessed via the internet, meaning companies no longer require expensive physical servers or heavy IT maintenance.

Benefits of Cloud ERP for UK Manufacturers

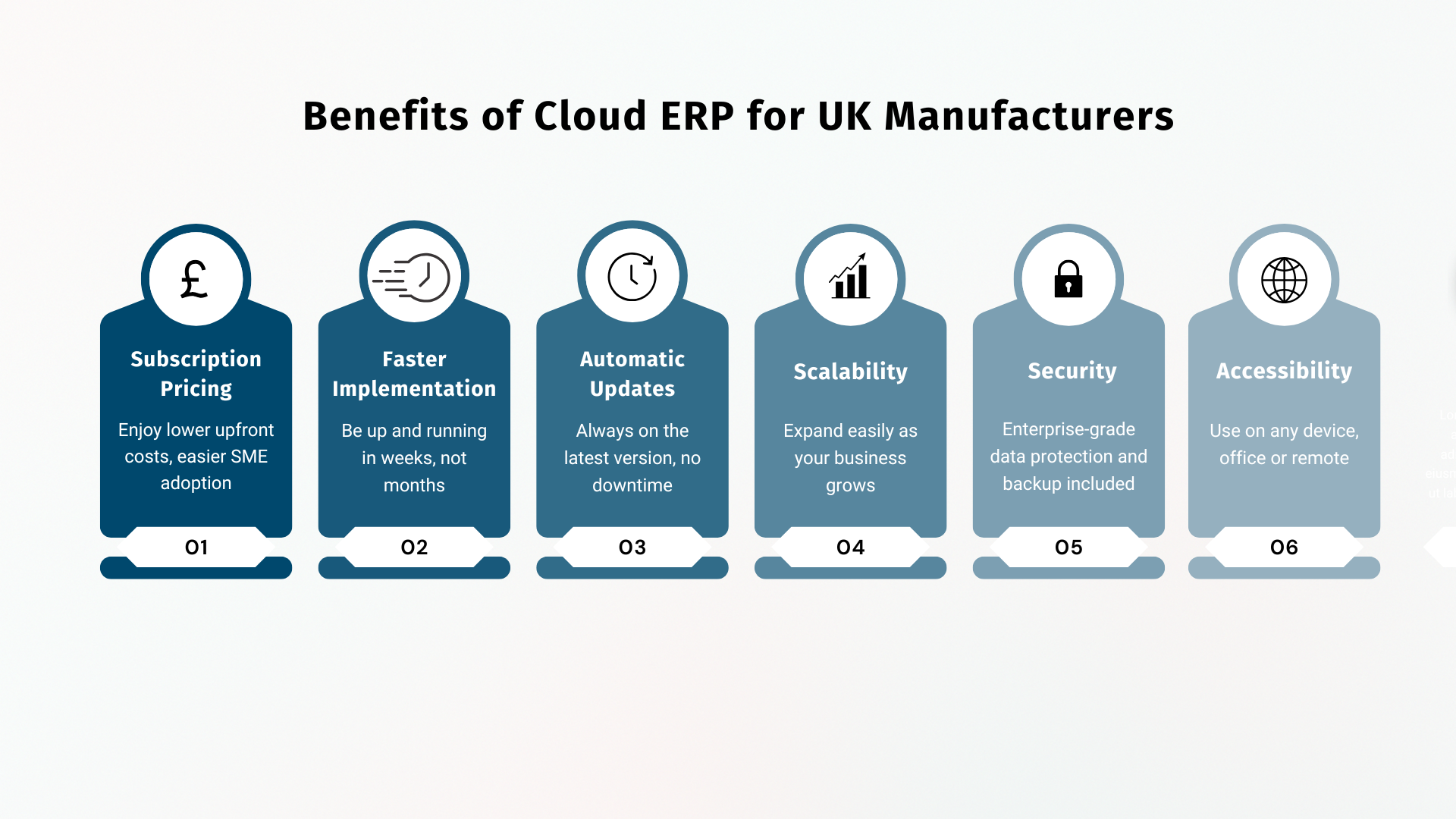

Cloud ERP offers many advantages for both small and mid-sized manufacturers. By moving ERP to the cloud, companies can reduce costs, further streamline their operations and enjoy better visibility across the business. Let’s look at some of the key benefits:

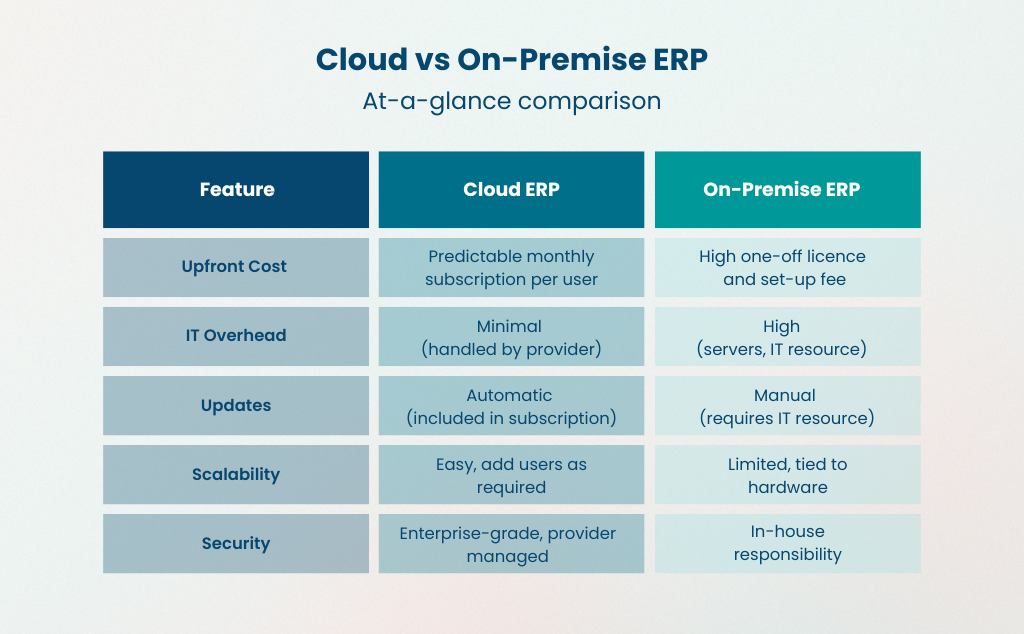

1. Lower upfront costs (OPEX vs CAPEX)

Traditional on-premise ERP systems require significant capital investment in servers, IT infrastructure, and licensing. Cloud ERP for manufacturers is subscription-based, turning large upfront costs into manageable operating expenses (OPEX). This makes it easier for SMEs to adopt a full-featured ERP without tying up capital.

2. Faster implementation and deployment

Cloud ERP systems are hosted online, removing the need for complex hardware installation and IT setup. Manufacturers can go live in weeks rather than months, accelerating benefits like better production tracking, WIP visibility, and integrated financial reporting.

3. Automatic updates and upgrades

A major advantage of cloud ERP is that software updates happen automatically. Your system is always running the latest version, with auto backups, new features, and security patches applied without disruption. This means your manufacturing processes remain efficient and secure without requiring in-house IT resources or untimely downtime.

4. Scalable as your business grows

Cloud ERP scales easily with your business. Whether you expand to multiple sites, increase your production volume, or add new users, cloud systems can grow easily without major IT investments or changes. This flexibility is particularly valuable for manufacturing SMEs aiming to expand operations or adopt new manufacturing technologies.

5. Secure & compliant (GDPR, ISO standards)

Cloud ERP providers invest heavily in enterprise-grade security, including data encryption, secure access controls, and disaster recovery. Many systems are also designed to comply with UK and EU regulations such as GDPR and ISO standards. Manufacturers can be confident that their sensitive production and financial data is safe.

6. Anytime, anywhere accessibility

With cloud ERP, authorised users can access the system from anywhere with an internet connection. This supports multi-site operations, remote work, and on-the-go decision-making. For manufacturers with production, warehousing, and sales teams in different locations, this real-time access improves collaboration and responsiveness.

How Cloud ERP Helps Manufacturing Operations

For UK SME manufacturers, managing production, stock, quality, and finance efficiently is critical. Manufacturing cloud ERP systems streamline these operations, providing real-time insights and automation that improve productivity, reduce errors, and support data-driven decision-making. Here’s some key operational benefits:

WIP Tracking

WIP tracking functionality gives manufacturers real-time visibility into work-in-progress across the production floor. This allows managers to monitor job status, identify bottlenecks, and allocate resources more effectively. An ERP system will also track components as they move through assembly, ensuring accurate reporting of WIP value for finance and production planning purposes. Accurate WIP tracking also helps reduce inventory discrepancies and supports faster month-end reporting.

Production Scheduling & Capacity Planning

Cloud ERP enables efficient capacity planning ERP and production scheduling by providing an integrated view of resources, machinery, and labour availability. Manufacturers can plan production runs, avoid overbooking machines, and reduce downtime. For instance, if demand spikes unexpectedly, cloud ERP allows production managers to quickly adjust schedules, reallocate resources, and maintain on-time delivery. This flexibility is especially valuable for SMEs with limited resources, helping them maintain consistent output without costly delays.

Quality & Traceability

Manufacturers must maintain high standards of quality while ensuring compliance with UK and EU regulations. Traceability functionality in cloud ERP allows manufacturers to track batches, serial numbers, and quality inspections at every stage of production. This makes it easy to identify root causes of defects, manage recalls if necessary, and maintain compliance with standards such as ISO 9001. Real-time traceability also improves customer confidence and strengthens reporting for audits.

Integration with Other Software

A key advantage of ERP software is the ability to integrate seamlessly with other business systems, such as accounting software, Outlook, MES, or QMS platforms. This eliminates manual data entry, reduces errors, and ensures consistency across finance, production, and quality management. For example, production data captured in the ERP can automatically update financial reports, improving decision-making and operational efficiency across the business.

Implementation for SMEs

Implementing a cloud ERP system may seem complex, but with a structured approach, manufacturing SMEs can achieve a smooth rollout that delivers maximum value. Cloud ERP implementation typically involves five key stages, each designed to minimise disruption and accelerate benefits:

1. Discovery & requirements gathering

The first stage involves understanding your business processes, current pain points, and operational goals. SMEs should engage key stakeholders from all departments, and particularly production, finance, and quality management, to map workflows and identify the modules required. This step ensures that the ERP system is tailored to the unique needs of your manufacturing business.

2. Data migration

Accurate data migration is critical for a successful ERP implementation. This involves transferring historical data from spreadsheets, legacy systems, or manual records into the new cloud ERP platform. Cloud ERP systems often include tools to streamline data import and validation, reducing errors and saving time. Proper data migration ensures real-time, accurate reporting from day one.

3. Configuration & setup

During this stage, the ERP system is configured to match your business processes. This may include setting up production scheduling, capacity planning, financial reporting, traceability workflows, and user permissions. Configuring the system to mirror existing processes while incorporating best practices helps SMEs optimise operations quickly.

4. Training & adoption

User adoption is crucial to realising the full benefits of cloud ERP. Role-based training should be provided to all key personnel, including production managers, sales teams, and operational staff. Cloud ERP platforms like E-Max ERP often include online training resources, help documentation, and dashboards to simplify learning. Early involvement of key users encourages engagement and reduces resistance to change.

5. Go-live & support

Once the system is configured and users are trained, the ERP can go live. Cloud ERP systems typically allow phased rollouts to ensure a smooth transition. Ongoing support from the ERP provider, including helpdesk services and updates, ensures issues are resolved quickly and the software continues to deliver value.

Timeline: For most UK SME manufacturers, a full cloud ERP implementation takes between 6-9 months, depending on the complexity of processes and number of users.

Tip: Involve Key Users Early

Engaging key users from day one reduces adoption issues, improves data accuracy, and ensures the ERP system reflects real operational requirements. Their input helps customise dashboards, reports, and workflows to suit the needs of your manufacturing business.

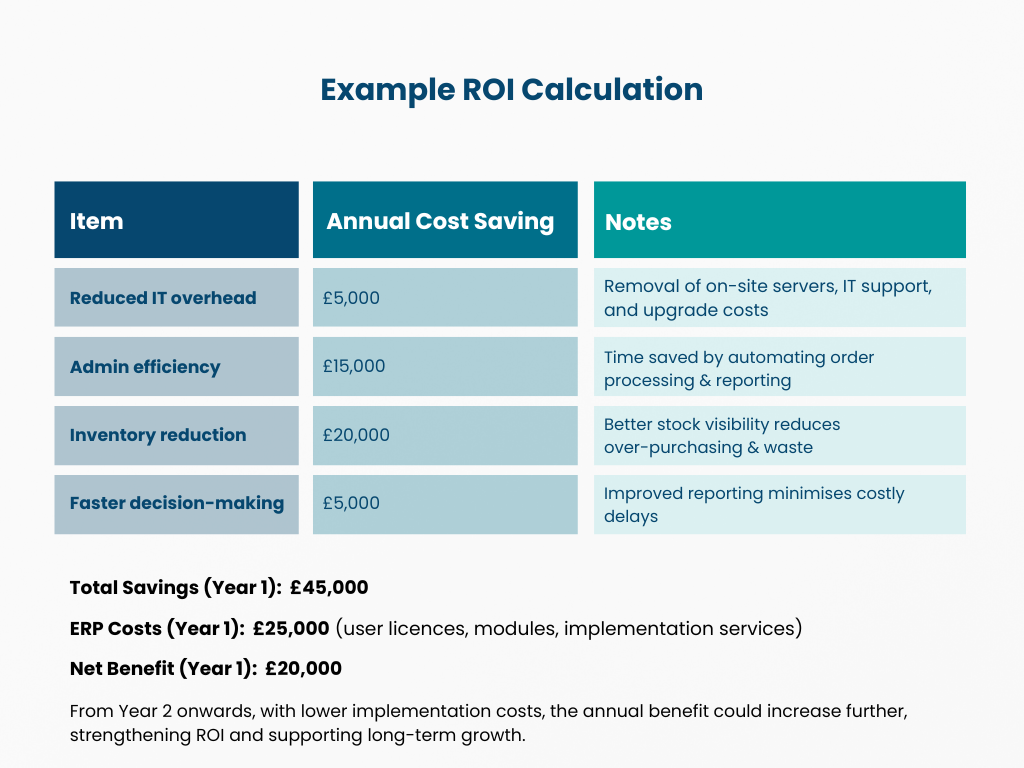

Costs & ROI of Cloud ERP for UK SME Manufacturers

When considering a new ERP system UK, one of the first questions most SME manufacturers ask is: 'how much does Cloud ERP cost, and when will we see a return on investment (ROI)?' The answer depends on the size of your business, the number of users, and the functionality you choose.

Typical Cloud ERP Costs

- Licence model: Most cloud ERP solutions, like E-Max ERP, are priced on a per-user, per-month basis, meaning you only pay for what you need.

- Modules: Costs scale depending on the functionality you require – for example, adding advanced modules for production scheduling, traceability, or WIP reporting.

- Implementation services: Optional services such as data migration, business process reviews, and tailored training can be factored in to ensure a smooth rollout.

This OPEX model (operational expenditure) is often more manageable for SME manufacturers than traditional on-premise ERP, which typically requires significant upfront investment in servers and infrastructure, often presenting a barrier to entry .

Cost Savings & Efficiency Gains

A cloud ERP system delivers measurable savings by:

- Reducing IT overheads (no server maintenance, backups, or upgrades required).

- Automating manual tasks such as purchase order approvals, cutting administrative workload.

- Enabling faster, data-driven decisions with real-time reporting and dashboards.

- Improving stock control and production planning, reducing waste and excess inventory.

ROI Timeframe for Manufacturers

Most UK SME manufacturers achieve ROI within 12–24 months, although some see benefits much faster. Savings are not just about IT costs, but also operational improvements, fewer errors, and better financial visibility.

FAQs

How much does cloud ERP cost for manufacturers?

Cloud ERP systems are typically priced on a per-user, per-month basis. For SMEs in the UK, entry-level plans start at around £50–£100 per user, with costs scaling depending on the number of users and the modules required. Unlike on-premise systems, you avoid large upfront hardware investments.

Is cloud ERP secure for SMEs?

Yes. Leading cloud ERP providers use enterprise-grade security, including data encryption, two-factor authentication, and regular backups. For UK manufacturers, cloud ERP can also help with compliance requirements such as GDPR, as data handling is managed to strict standards.

Can cloud ERP scale as my business grows?

Absolutely. Cloud ERP is designed to scale with your company. You can add new users, sites, or modules as needed without investing in new infrastructure. This makes it particularly suited to growing SMEs in the manufacturing sector.

See the Benefits of Cloud ERP in Action

Cloud ERP systems like E-Max ERP help UK SME manufacturers gain full visibility of WIP tracking, optimise capacity planning, improve traceability, and streamline finance and operations in one integrated system. By reducing manual processes, cutting IT overheads, and enabling faster, more informed decision-making, manufacturers can achieve a rapid ROI and support future growth.Now that you know the benefits of cloud ERP for manufacturers, why not see it for yourself? Book a free no-obligation demo of E-Max ERP today and explore how an ERP system UK solution can transform your operations. Call us on 0808 109 2035 or drop us a message and our friendly team will be happy to help.