9 reasons why companies NEED an ERP system

Many small to medium sized companies still question whether they really do need an ERP system. Day to day activities are already all-consuming without adding the challenge of finding and implementing a new system across your business. After several troublesome years, things are finally getting back to a more even keel, with your business moving along, seeing some growth, still getting orders, turning a bit of a profit and generally getting by ok. So why rock the boat and spend time and money on a new system?

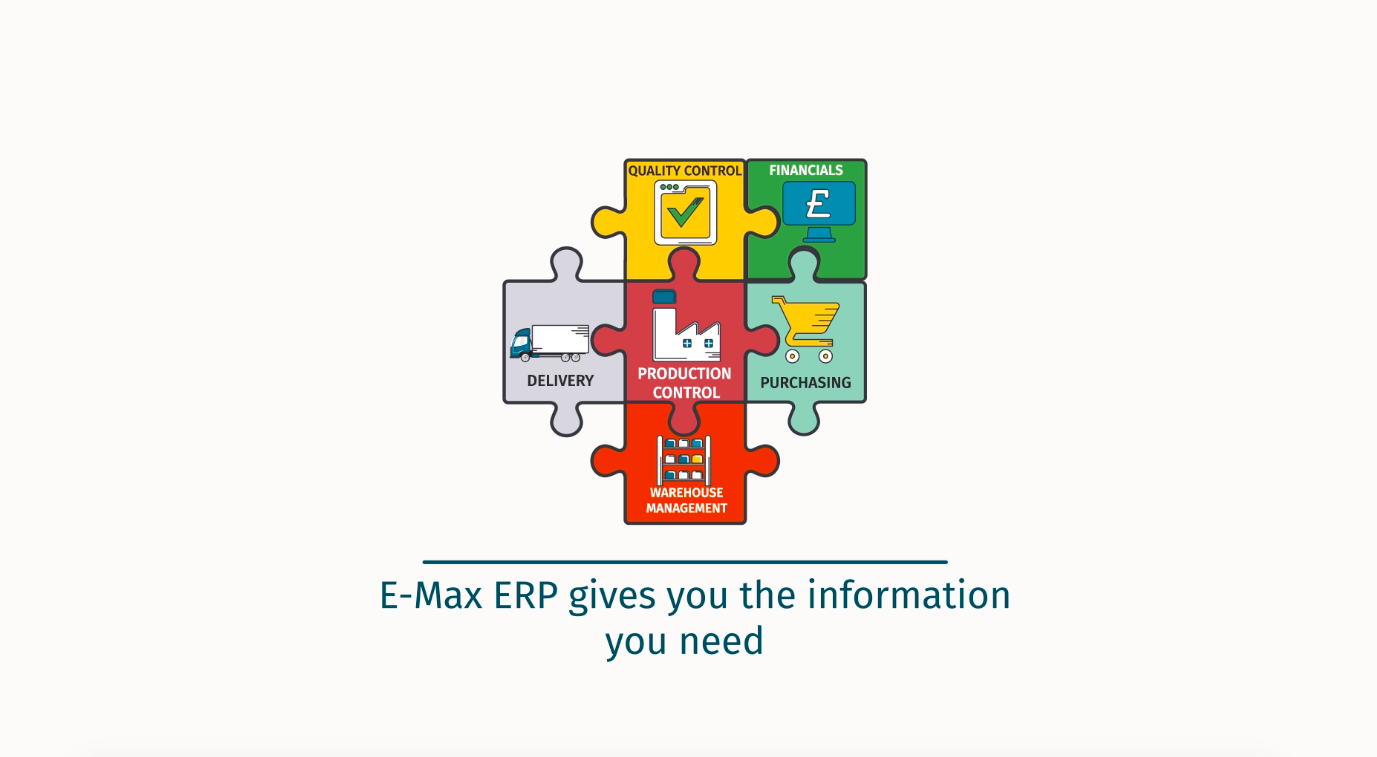

It’s simple. There’s no doubt that ERP systems bring multiple benefits to businesses, especially manufacturing companies. Whilst some companies still resist the idea of needing an ERP system, citing cost, being too busy, too small or managing with spreadsheets as justification, most progressive and ambitious businesses are recognising the opportunities an ERP system can provide them. Not convinced? Here’s the top 9 reasons our clients gave us as to why they need an ERP system:

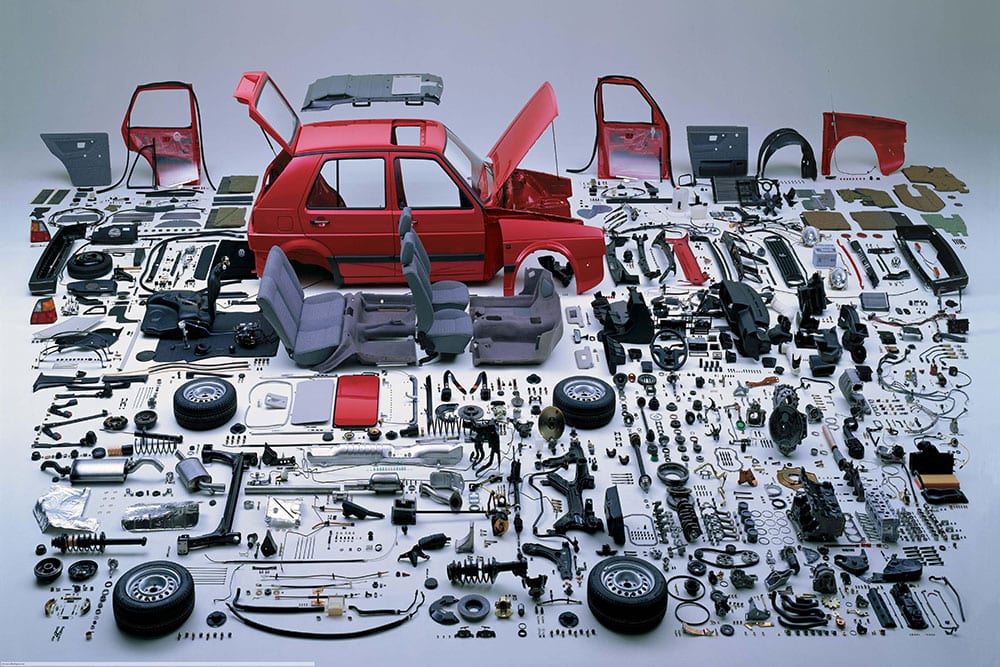

1. We want to increase our efficiency

No company wants to be carrying unnecessary stock when they can avoid it. An ERP system enables you to know exactly what stock you need for each job and when you need it. ERP software also allows you to automate many of your processes so efficiencies can be created across the entire production process. This means less duplication, better scheduling of resources and reduced downtime.

2. Our existing systems don’t do the job

Plenty of companies struggle with a legacy system which may once have done the job but is now woefully inadequate to do the job of the modern ERP system. Eventually you’ll find that this is no longer sustainable, whether through lack of vendor support, a knowledge gap created when users leave or just plain old lack of functionality stopping you from getting any meaningful information.

3. We’ve got too many spreadsheets

The humble spreadsheet might once have been a fantastic resource to store your data and even provide some basic analysis of that data but it’s long been surpassed by the ERP system. Multiple spreadsheets in companies are still a common occurrence but as your company has grown, you’ve probably got too much information to be handled by your existing spreadsheets alone. Do you really want to add yet another spreadsheet to your mix? An ERP system replaces spreadsheets whilst bringing together all your data and giving you real time answers.

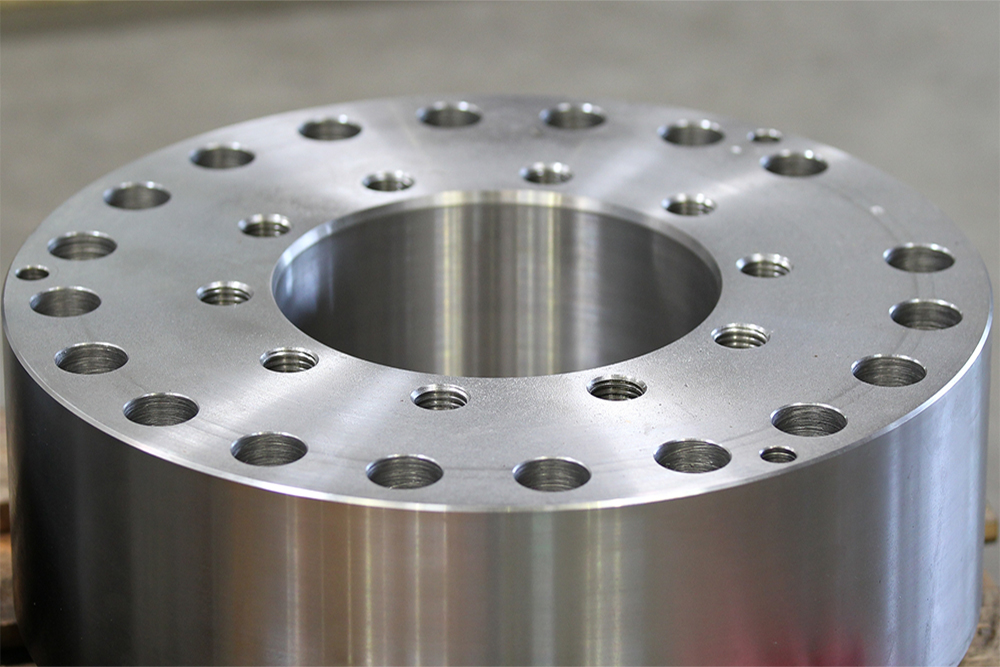

4. We need better functionality

In today’s accountable society, many jobs require accurate traceability. Working in supply chains for major sectors like aerospace, automotive or defence allows no room for errors or delays. If you want to bid on – and win – contracts in these sectors, you’ll need a system in place that can provide full traceability, manage your stock levels, schedule your production floor and manage plenty of other functions. Yes, you’ll need an ERP system!

5. We want to minimise errors

An ERP system offers you the opportunity to reduce human error significantly. Where departments use their own standalone systems, incorrect or inconsistent data can be entered into each system. With ERP software, everything comes together so information only needs to be entered once. This information flows through the whole system, with each department accessing the correct original data. And because tasks and activities are also in the one system, it’s simple to check the status of these, so nothing slips through the cracks when your employees are on holiday or off sick.

6. It’s time to consolidate our data and get real time info

You may be using a range of spreadsheets or have multiple ‘best of breed’ systems but do they fully integrate with each other to give you a full picture of what’s happening in your business? Without having all your data in one place, it’s difficult to make big decisions about what needs to be done. An ERP system usually includes a dashboard which displays your KPIs and flags any exceptions. The beauty of having your data in the one system is that all the information about an order is in one place – from the initial enquiry right through to the invoicing giving you easy access to every job.

7. We need to gain ISO accreditation so we can move into new markets

Certain industries and companies demand their suppliers are quality accredited. Whilst gaining accreditation can be a long process, it is significantly easier with a good ERP system in place. You need an ERP system to support your business’s end-to-end processes and ensure standardisation and process uniformity are the norm. Checks can be built in to an ERP system to guarantee that procedures are adhered to, resulting in consistent quality working practices – the key factor in achieving ISO accreditation.

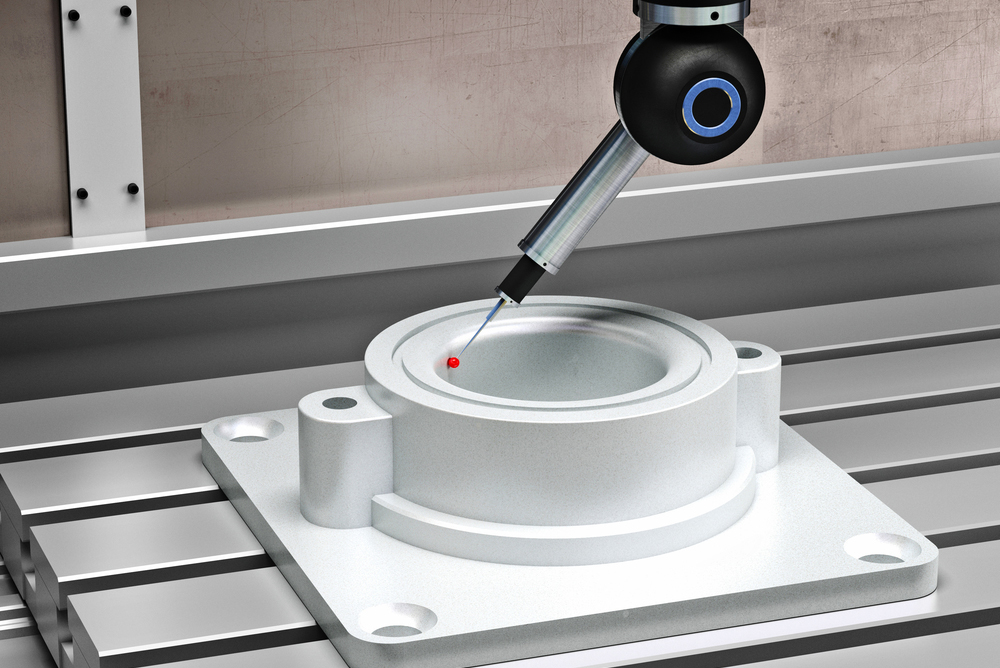

8. We’ve got no visibility of what’s happening on the shop floor

You know you’ve got plenty of jobs on the books but do you have any idea of the status of any of them? This lack of visibility can be costly and frustrating and means you’re most likely being reactive rather than proactive. AN ERP system will track all your jobs from enquiry through to invoice and, what’s more, will schedule them in to maximise the efficiency of your shop floor capacity.

9. We want to increase the value of our company and grow

It’s hard to increase the value of your company when you’re relying on outdated systems and spreadsheets. Owners looking for an exit strategy from their business can create greater order and control by bringing in an ERP system to reduce inventory, streamline processes and speed up the flow of jobs through the company, resulting in an improved bottom line. Greater efficiency allows you to become more competitive and offers solid growth prospects.

How many of these reasons resonate with you? If you’re thinking that you may well need an ERP system, then give us a call on 0808 109 2035, drop us an email or visit our website for more information. You can also arrange a free demo with us to see E-Max ERP in action.